Metal Forming and Materials Modelling

Our mission is to provide solutions and develop applications in metal forming through industrial collaboration, drawing on knowledge and experience using available resources.

Our mission

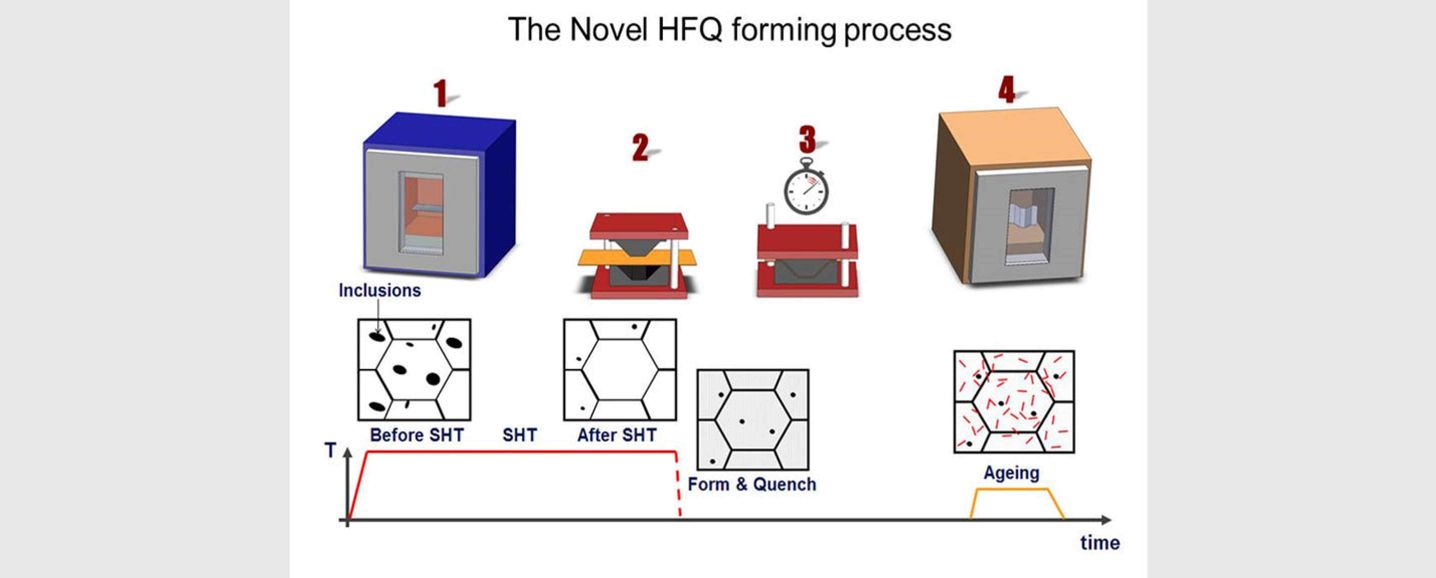

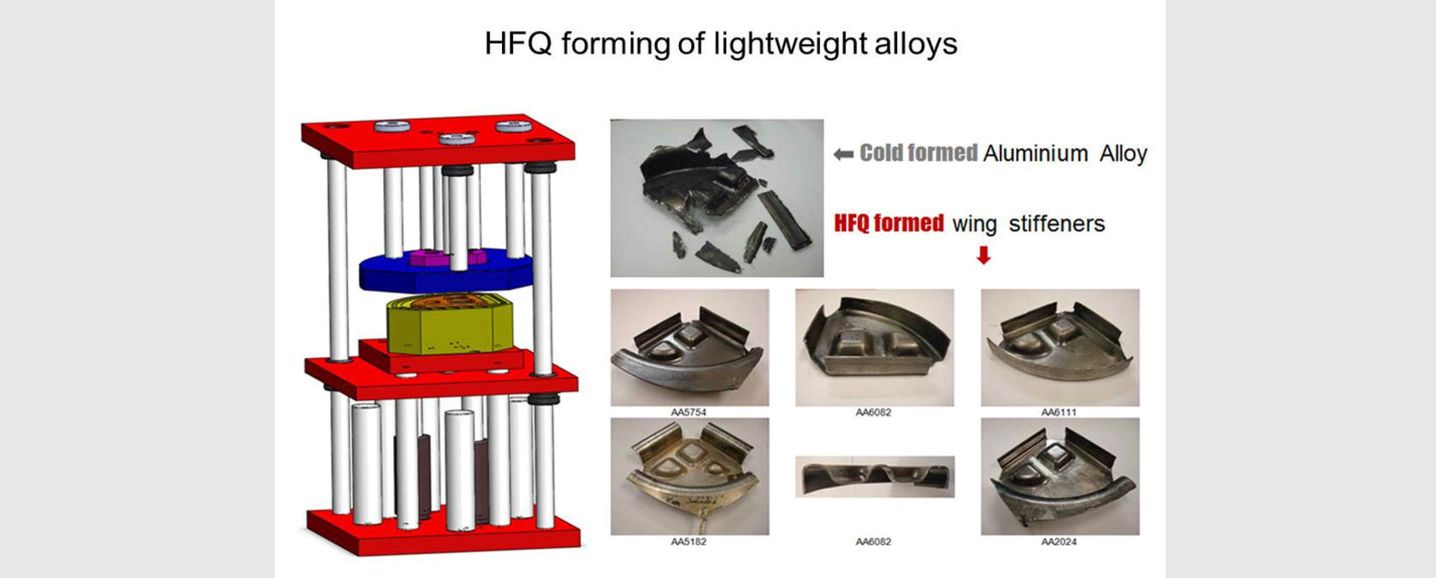

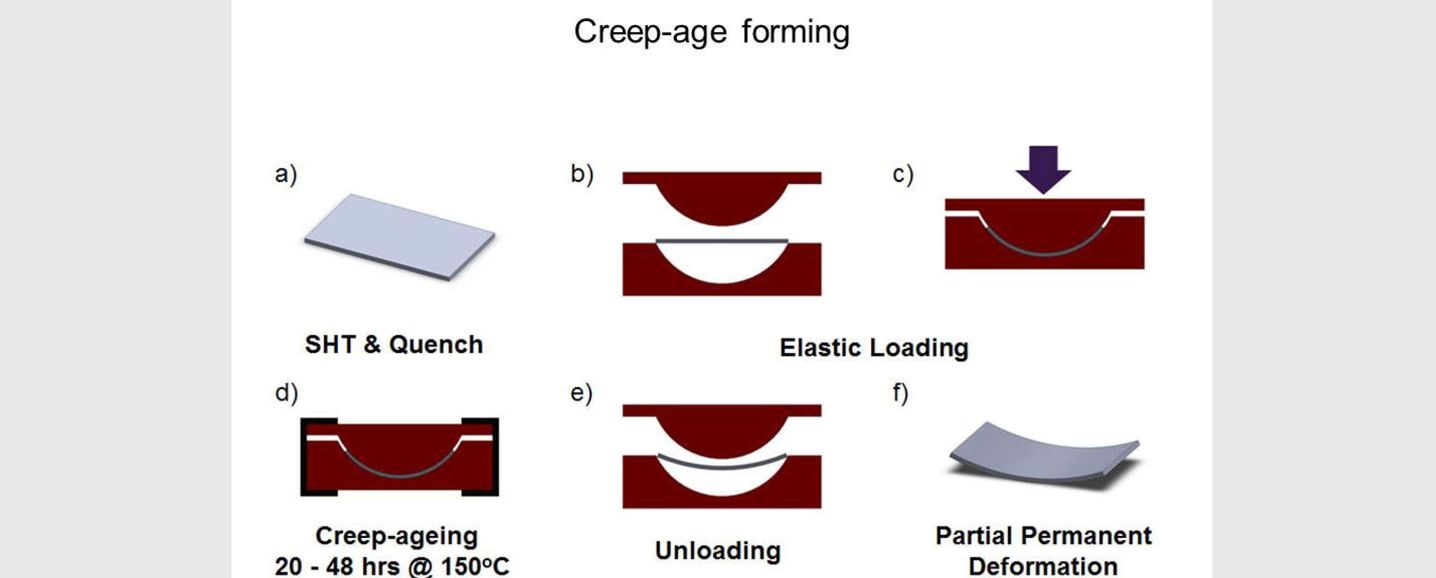

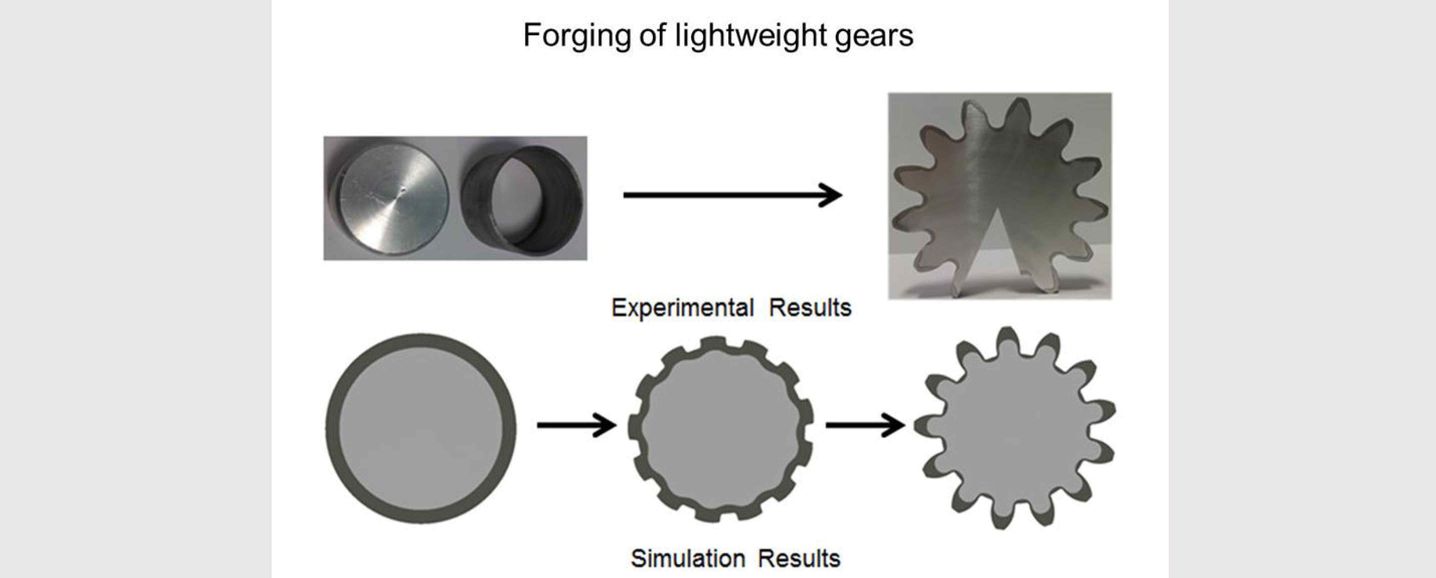

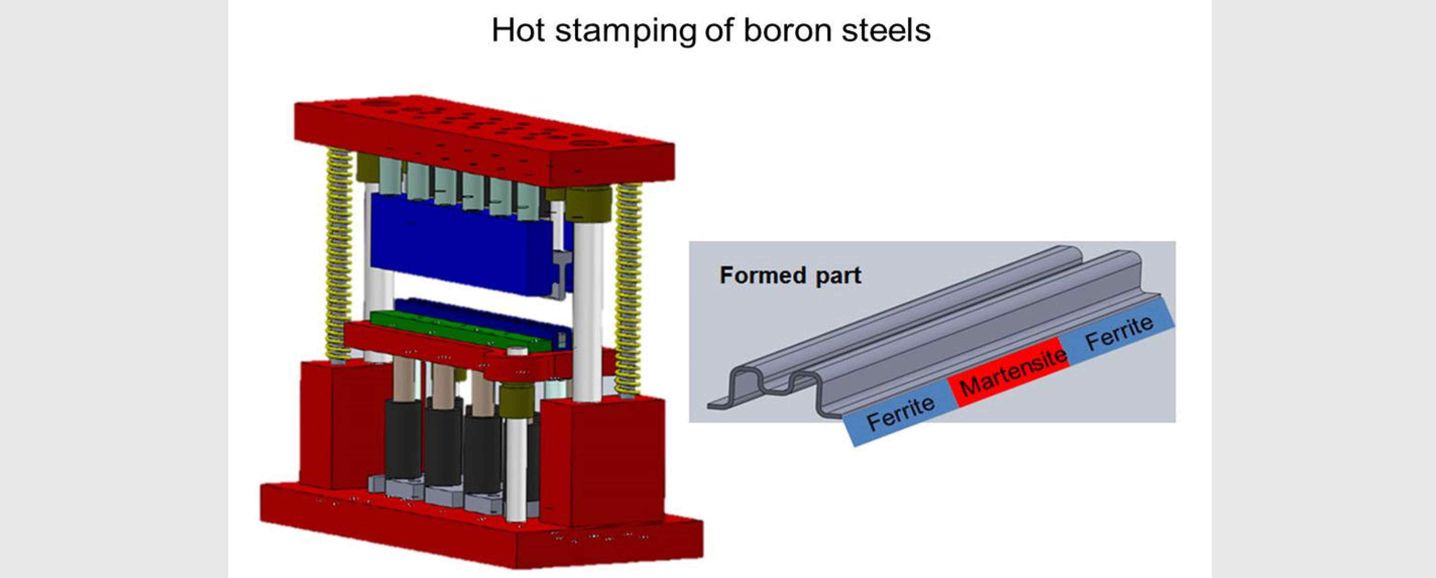

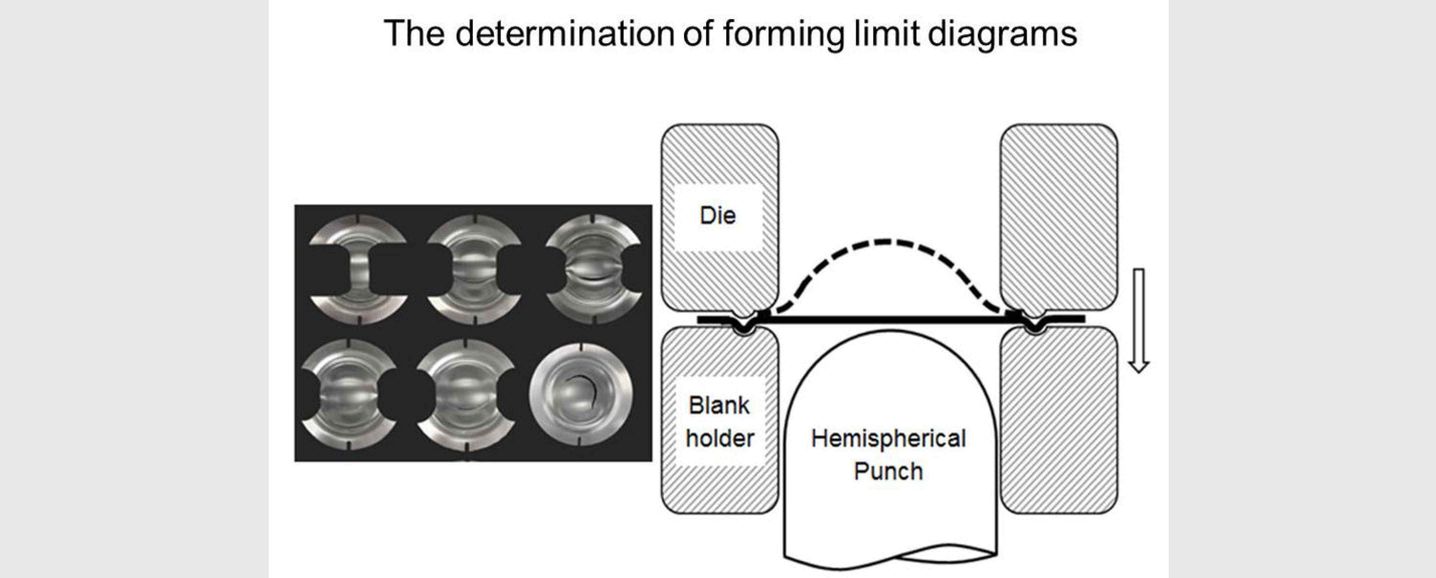

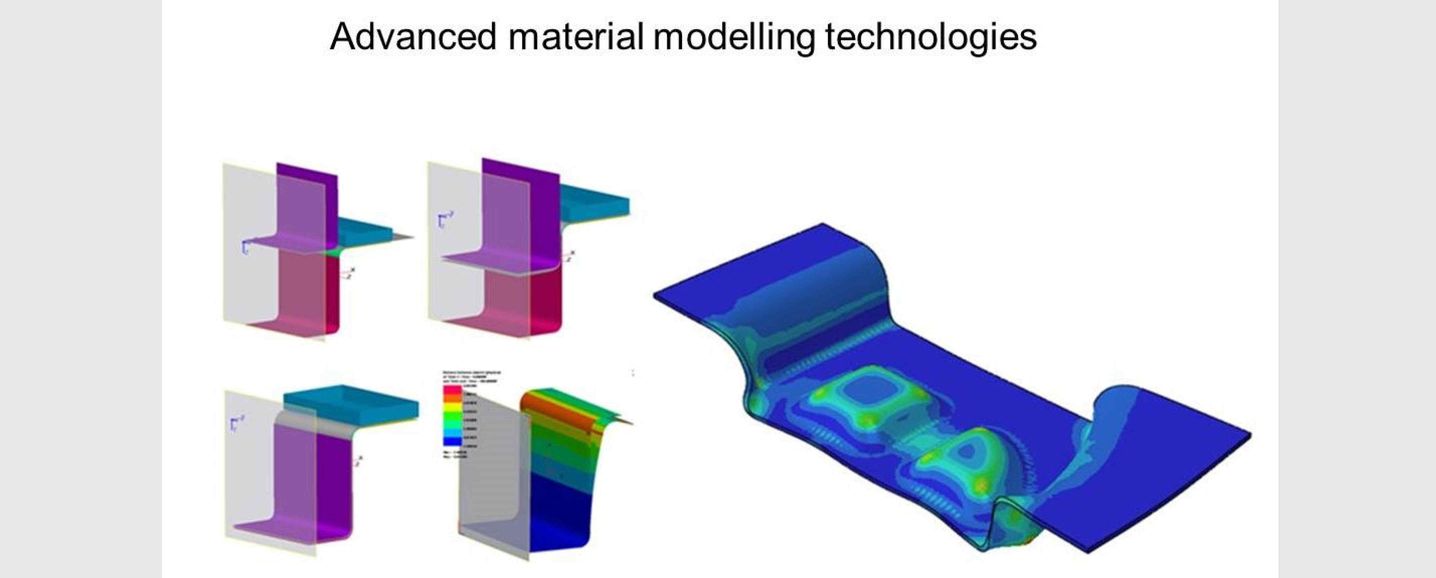

Metal Forming and Materials Modelling works on a range of metal forming processes, such as rolling, forging, extrusion, sheet metal forming, warm forming, hot-stamping and cold-die quenching for boron steel and Aluminium alloys, creep age forming, spin-forming, cross-wedge rolling, etc.

Our mission is to provide solutions and develop applications in metal forming through industrial collaboration, drawing on knowledge and experience using available resources. The key research is related to the development of unified constitutive equations to predict microstructure evolution in thermomechanical forming processes.

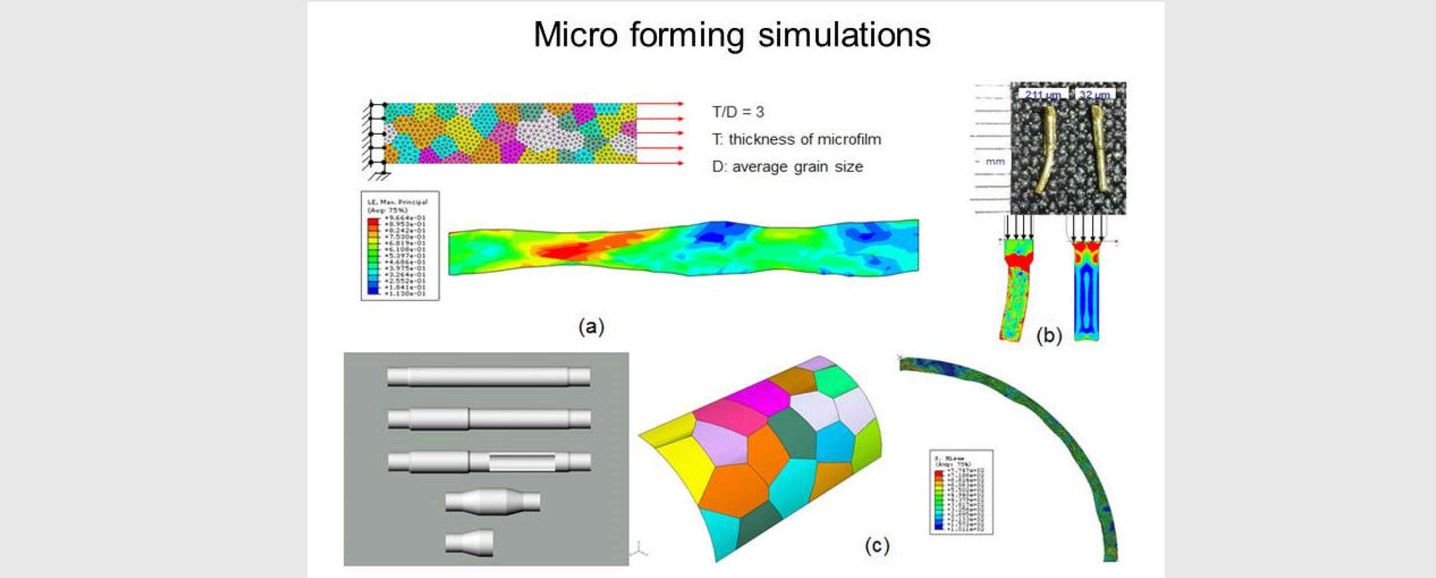

Multiscale materials modelling is also carried out for the purpose of understanding fundamental aspects of materials deformation. New equations informed by discrete modelling are being introduced for mechanisms such as grain boundary sliding and rotation, and the interaction between dislocations and grain boundaries, so that previously inaccessible deformation modes, such as superplasticity, can be captured by the unified constitutive equations.

Advanced computational techniques such as XFEM are used to model the material and displacement discontinuities that occur at grain boundaries and interfaces.

Industrial collaboration

The group has extensive experience in developing new forming technique for industrial applications. Three industry-sponsored research centres have been established within the group with the aim to explore the frontiers of metal forming and modelling in the aviation, aerospace and railway industries. More details of the centres can be found as below.

CRRC Sifang - Imperial Centre for Rail Transportation Manufacturing Technologies