Prof. M. Titirici (MT, ICL), Prof.S. Vignolini (SV, UCAM), Prof. S. Eichhorn (SE, Bristol), Prof. J. Hallett (JH, ICL), Prof. N. Shah (NS, ICL), Prof. C. Petit (CP, ICL), Dr. I. Stephens (IS, ICL), Dr. C. Mattevi (CM,ICL), Dr. A. Brand Talbot (ABT), Prof. J. Jones (JJ, ICL), Dr KY Lee (KYL, ICL), Prof. M. Heeney (MH, ICL), Prof. J. Nelson (JN, ICL), Prof. P. Dupree (PD, UCAM), Dr. P Yaseneva (PY, UCAM), Prof. A. Lapkin (AL, UCAM)

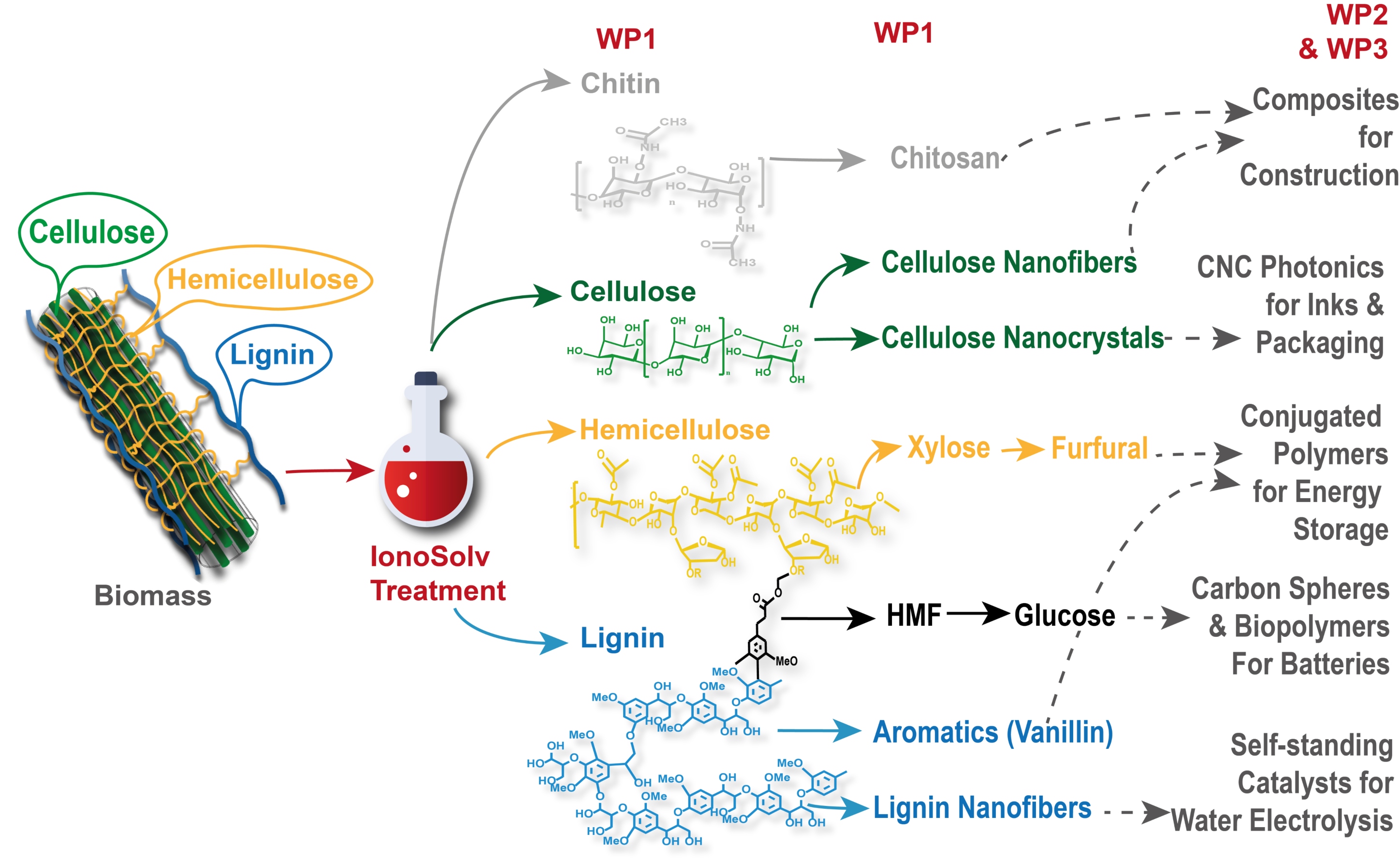

WP1: Creating a local and sustainable raw materials supply chain, led by JH

This WP is establishing design rules based on a fundamental understanding for green and efficient harvesting of bio-based precursors from food, forestry, and agricultural waste provided by our project partners. Multidisciplinary expertise in plant biochemistry for understanding the cell wall of different biomass streams (PD) is key, allowing both the design of tailor-made materials (as in WP2) and the development of sustainable solvents (JH) to extract desired pure components from biomass (e.g., cellulose, lignin, chitin, pectin, hemicellulose) and further convert them into chemicals (e.g., fructose, glucose, xylose, furfural, 5-hydroxymethylfurfural) in a reproducible and saleable manner. These biorefinery routes are being supported by LCA (NS-WP5) to ensure sustainability and optimised using ML (AL-WP4) and HT approaches (CP-WP4).

WP2: Bio-derived advanced materials and processes (SV lead)

Is developing engineered “on demand” processable materials based on different precursors from WP1 to enable sustainable manufacturing of advanced materials with tailored properties. The consortium has vast expertise in low TRL sustainable materials manufacturing based on hydrothermal processes (MT), fibre spinning (MT, SE), solution spinning (SE, ABT), self-assembly (SV), and solid-state approaches (KYL, JJ). Examples of materials include carbon spheres, enzyme mimetics (nitrogenase, cytochrome C) based on Fe-N complexes supported on carbons, lignocellulosic-based carbon fibres, bio-composites based on cellulose/carbon fibres, CNCs, photonic materials and inks, conjugated polymers from lignin/furanes. HT methods (CP, WP4) are being applied to accelerate materials discovery and optimise their properties using ML (AL-WP4), while being screened for sustainability (NS-WP5). Processing via printing techniques/additive manufacturing is being applied for scalable production of 3D structures to be directly used in different applications in WP3.

WP3: Scaled materials with targeted functionality (MT lead)

Is optimising and upscaling advanced materials from WP2 in targeted applications, bridging the gap between different scales, manufacturing methods, and performance/durability. They are being directed by the most promising performance based on sustainability assessments from WP5, as well as optimisation and prediction modelling in WP4. Applications are being explored in important sectors of the UK economy that need to be decarbonised. Employing net-zero materials based on abundant and locally available precursors is creating truly sustainable solutions. Materials synthesised in WP2 are being assessed for fuel cells and electrolyser catalysts (IS, MT, CM), NH3 electrosynthesis (IS), alternative batteries beyond Li-ion (e.g., Na, K or organic) (MT), mechanical robustness for buildings, sustainable structural colour, and leveraging the flexibility afforded by a PG, new applications that are yet to be discovered.

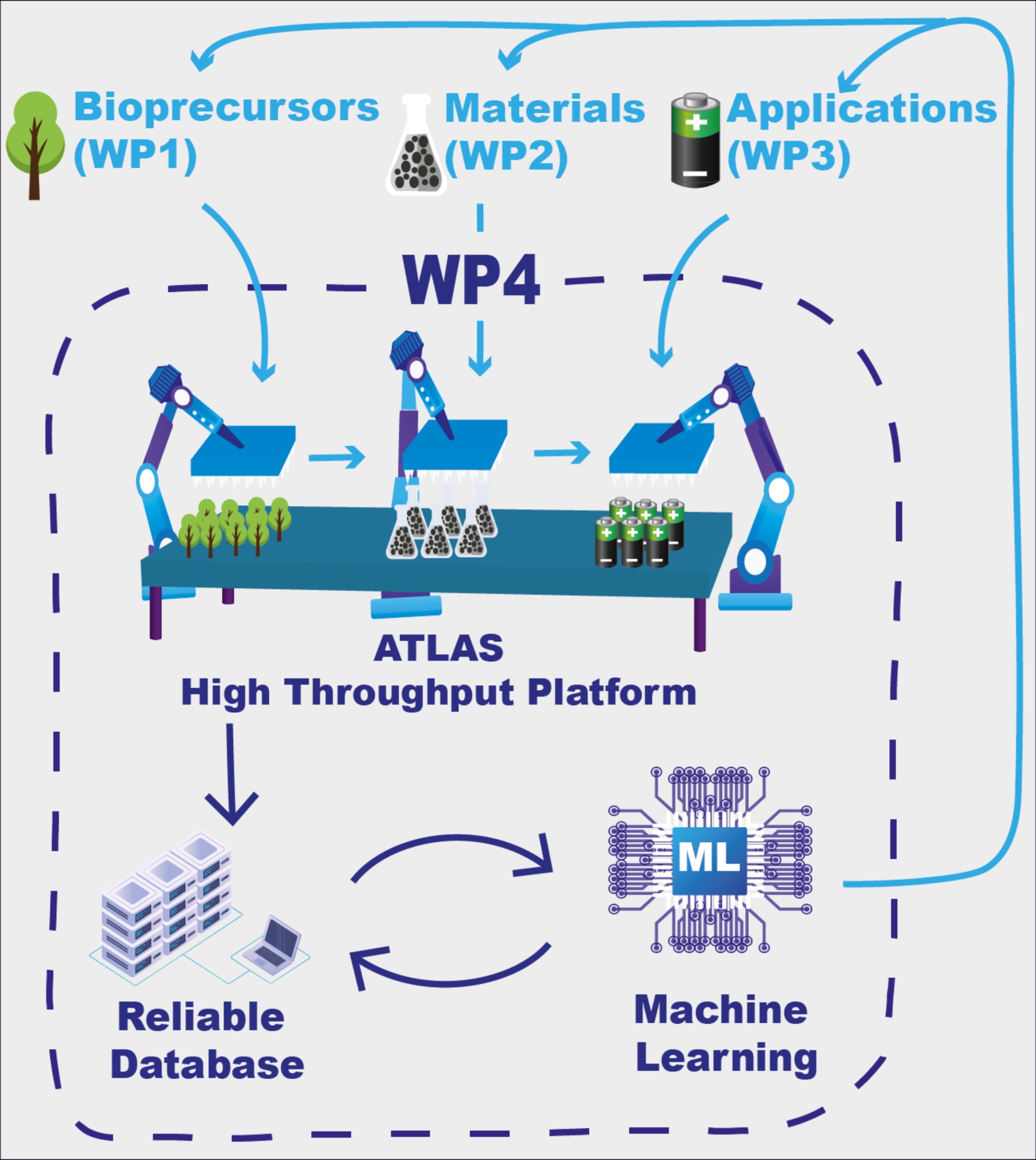

WP4 Optimisation via high throughput (HT) experiments powered by artificial intelligence (AL lead)

Is applying automated experimental workflows (using the recently funded EP/V029142/1; ATLAS - automated high-throughput platform suite for accelerated molecular systems discovery). The workflows cover WP1-3, from optimising extractions to employing different bio-waste precursors (e.g., different ionic liquids, temperatures, mixing ratios, shear mixing) to some of the materials synthesis and processing. In terms of materials synthesis, the workflows include hydrothermal carbonisation under different conditions (temperature, concentration, pressures, feed gas), mixing of biomass precursors and derived materials for bio-composites, optimising the size and functional groups of cellulose nanocrystals (CNCs) by applying different precursors and hydrolysis times. In terms of processing, we are covering different applications, e.g., printing inks for electrodes via precise shear mixing of accurate amounts of components and coating onto various conductive substrates with controlled thickness and homogeneity. HT outputs, combined with characterisation methods and performance data (see WP3), are forming reliable and reproducible data sets that can be used by ML algorithms to understand and optimise raw precursors from biomass, materials, processes, devices, and systems in the context of WPs1, 2 & 3.

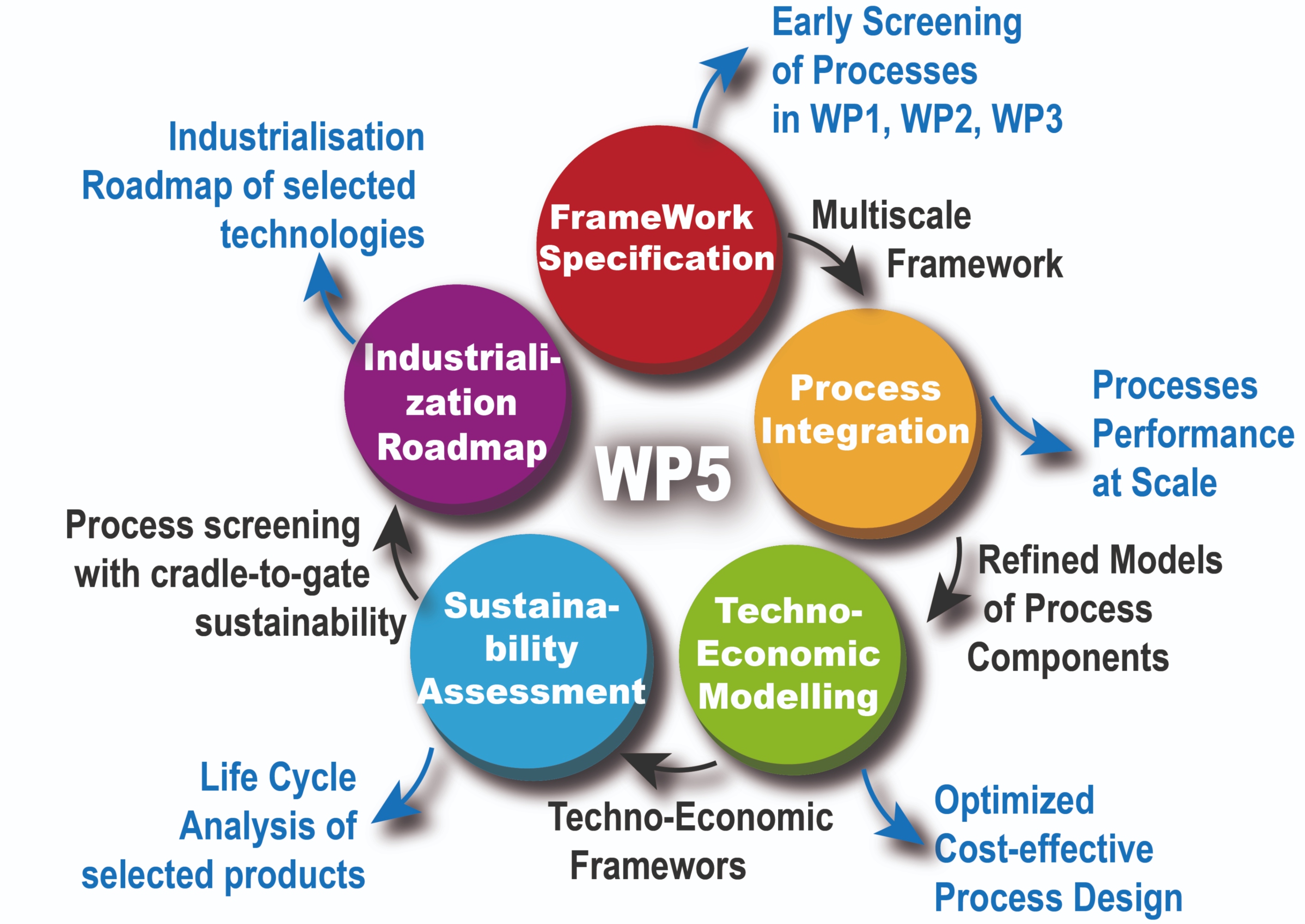

WP5: Techno-economic and sustainability assessment and optimisation from raw materials to applications (NS lead)

Demonstrates the USPs of the next generation of sustainable and durable devices produced using locally sourced sustainable materials and shows value advantages over current technologies, ensuring no unintended consequences arise from these new process pathways. Predictive modelling coupled with LCA using the consortium’s preliminary data initiates the PG, using the most environmentally friendly processes and valuable materials. LCA/TEA is used over the project’s duration, setting the direction for the development of the most promising technologies and providing continual screening and feedback.