Completed Research Projects

- Abigail Ackerman - Secondary Alpha in Ti-6Al-2Sn-4Zr-6Mo

- Dr Ioannis Bantounas – Effect of Microstructure & Micro-Mechanisms Responsible for High Temperature Mechanical Properties of Co-Based Superalloys

- Chris Collins - The effect of nitrogen on Ti-6Al-4V

- Peilong Dong - Atmospheric Stress Corrosion Cracking of Low Carbon Austenitic Stainless Steels...

- Dr Claudia Gasparrini - Neutron irradiation damage of nuclear reactor pressure vessel steels

- Tianhong Gu - EBSD studies of the evolution of microstructure and damage during the thermal cycling of Pb-free solder materials

- A CIP-HIP Method for the Production of Near Net Shaped Titanium Components

- Alloys by Design: Coupling Quantum Mechanical Models into Microstructural Simulations for the Prediction of Complex Microstructures

- Tansel Arif - Mesoscale modelling of steel processing

- Alpha Case Formation in Titanium Alloys

- Atomic Scale Theory and Simulation of High Temperature Shape-Memory Alloys

- Bartosz Barzdajn - Total life prediction from nucleation, short crack growth behaviour and linear elastic fracture mechanics

- Beta titanium at elevated temperatures

- Calculating Liquid State Thermophysical Properties from First Principles

- Patrick Burr - Atomistic modelling of Zr and Be intermetallics

- Characterise and model a gamma/gamma prime microstructure in a nickel-based superalloy

- Tamara Chapman - Fatigue cracking behaviour in Ti-6Al-2Sn-4Zr-6Mo

- Combinatorial Development of High Temperature Shape Memory Alloys

- Mitch Cuddihy - Cold dwell crack nucleation in titanium aeroengine components

- Creep Modelling in Polycrystal Nickel Superalloys

- Bernadette Elliott-Bowman - Thermomechanical processing of high carbon steel

- Tomiwa Erinosho - Strain path effects in ferritic steel polycrystals

- Defect Formation in Single Crystal Nickel-based Superalloys

- Deformation of Dendritic Structures in Directionally Solidified Al-Cu Alloys

- Peter Evans - TWIP beta-Ti armour and containment alloys

- Effect of Texture on Performance of Ti-6Al-4V

- Electrochemical Deoxidation of Titania-based Mixed Metal Oxides

- Farah Ismail - Oxidation and oxygen transport mechanism in Co-Al-W superalloys

- Electrochemical Reduction of TiO2 in Molten CaCl2

- Dr Jun Jiang - Micro-mechanical tests in aerospace materials

- Extrusion of Zr-2.5Nb for Pressure Tube Applications

- Dr Tea-Sung (Terry) Jun - Micromechanics of hexagonal polycrystals

- Fatigue Initiation and Micromechanics of Ti-6Al-4V

- Kristina Kareh - In situ synchrotron tomography of granular deformation in semi-solid Al-Cu alloys

- In situ synchrotron characterisation of Fe-rich intermetallic formation during the solidification of Al-Si-Cu-Fe alloys

- Investigation of the effect of lanthanum on the oxidation of CMSX-4

- Matthias Knop - Deformation behaviour of Co-base superalloys

- Microstructural Investigation of Nickel-based Superalloys

- Modelling the Melt and Mreeze Behaviour of Materials for the Next Generation of High

- Multiscale Modelling of Continuous Casting Processes

- New Materials for Long Life Flare Tips

- Wenjun Lu - Microstructure processing for steels

- Oxidation and oxygen transport in a commercial polycrystalline Ni-based superalloy under static and loading conditions

- Simulation of the Mechanical and Flow Behaviour of Bone Fixation Implants

- Paul Mulvey - Development of Co-based superalloys

- Stress Corrosion Cracking of Metal Packaging for Foods

- Dr Maelig Ollivier - Influence of contact reactions and thermal treatments on the surface of pure silver

- Superelastic beta titanium

- Dr Daniela Proprentner - Oxidation damage at a crack tip and its significance in crack growth under fatigue-oxidation conditions

- Other projects

- Dr Khandaker M Rahman - Blast performance of TWIP steels

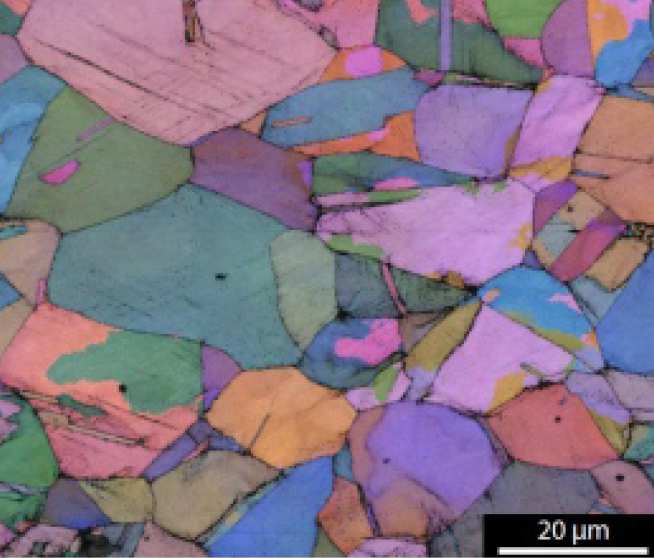

- Anna Radecka - Short-range ordering and the deformation mechanisms of Ti-7wt%Al

- Alireza Rahnama - TMPC - Property relationships in strong steels

- Dr Ananthi Sankaran - Micro-mechanisms involved during high cycle fatigue of zirconium alloys

- Peter Tympel - The effect of complex loadi ng regimes on fatigue of Ti-6Al-4V

- Victor Wan - Fundamental modelling studies of crack nucleation and microstructurally short crack growth in superalloys

- Hannah Weekes - Micromechanics of hydrides in zirconium alloys

- Tiantian Zhang - Understanding fatigue crack nucleation from inclusions in a powder nickel alloy using micromechanics

- Dr Xinfang Zhang - A novel clean steel green processing method

- Dr Zebang Zheng-Investigation of slip transfer across grain boundaries within a crystal plasticity and discrete dislocation formalism with application

- Dr Alexander (Sandy) Knowles - Design and development of new materials for gas turbines – high strength titanium alloys

- Bo Chen - The Analysis of Fatigue Crack Nucleation & Propagation in Powder Nickel Superalloys using Crystal Plasticity Finite Element Modelling...

- Giuseppe Scatigno - Chloride-induced transgranular stress corrosion cracking of austenitic stainless steel 304L

- Dr Guang Zeng - Intermetallic nucleation and growth in Magnesium alloy solidification

- Hao Shang - Influence of Zn on the nucleation of beta-Sn in Pb-free soldering

- Hikmatyar Hasan - Multi-scale modelling of high-temperature deformation mechanisms in Co-Al-W-based superalloys

- Muzi Li - Characterisation and modelling of the mechanical properties of gamma prime phase in nickle P/M superalloy

- Ning Hou - Directional Solidification of Eutectic Pb-free Solders

- Osamudiamen Omoigiade - Microstructural Control of Pearlite

- Suki Adande - A micromechanical study of crystal orientation and coating chemistry in a graded engineering alloy

- Dr Vassili Vorontsov - High-resolution electron microscopy of Co-Al-W superalloys

- Dr Vivian Tong - Micromechanical Testing of HCP Alloys

- Zhalong Ma - Controlling nucleation and grain size in Pb-free solder

- Zhenqi Li - Composite Solder

- Dr Zhen Zhang - Microstructure-sensitive deformation mechanisms in high performance HCP alloys

- Dr Daniel King - Atomic scale modelling of nano-solute-vacancy clusters in reactor pressure vessel steels

- Vlad Podgurschi - Modelling the effect of iodine at stress corrosion crack tips in Zr using hybrid quantum mechanics/molecular dynamics simulations

- Lucy R Reynolds - Cobalt based Superalloy development

- Te-Cheng Su - In-situ synchrotron radiography and tomography studies of semi-solid deformation in Al alloys and steels

- Claire Trant - Fatigue in Gamma Titanium Aluminide

- Filippo Vecchiato - Microstructural evolution of 316l stainless steel in laser powder bed fusion

- William White - Discrete dislocation dynamics coupled with discrete solute diffusion to model the effect of hydrogen in steel

- Tom Whiting - Atomic-scale modelling of solute clusters in reactor pressure vessel steels

- David Wilson - Microstructurally sensitive modelling methodologies for crack nucleation and growth in Zr alloys

- Simon Wyatt - Understanding Crystallographic Texture Evolution in Two-Phase (hcp/bcc) Alloys

Investigator: Abigail Ackerman

Supervisors: Dr David Dye

Collaborators: Prof. David Rugg, Rolls-Royce plc.

Duration: 10/04/2014 - 10/01/2017

Description:Ti-6Al-2Sn-4Zr-6Mo (Ti 6246) is currently used in the HP compressor of gas turbine engines. Secondary alpha is the phase of the alloy that nucleates from primary alpha, growing within the beta grains and additionally at the grain boundaries. The presence of secondary alpha gives the alloy it’s strength, however little is known about its nucleation, growth and behaviour.

By investigating how the phase grows under differing processing conditions, it is hoped some insight will be gained into the development of secondary alpha in Ti6246. The project will include analysis of chemistry, morphology, grain orientations and behaviour under deformation.

Investigator: Dr Ioannis Bantounas

Supervisors: Prof. David Dye

Collaborators: Dr Mark Hardy, Rolls-Royce

Duration: 01/08/2015 – 01/08/2017

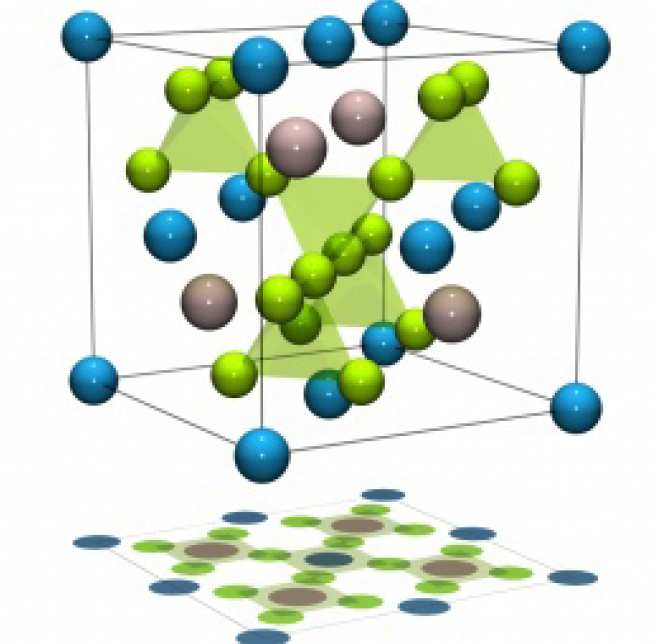

The discovery of the gamma prime L12 phase in the Co-Al-W ternary system has enabled the development of Co-based alloys with increased high temperature mechanical performance. Cobalt exhibits a higher melting point than nickel, the base material of current high temperature engineering alloy applications. Co-superalloys thus promise a higher upper limit for high temperature mechanical performance.

Applied to an industrial context, development of these alloys could realise increase gas turbine inlet temperatures. This in turn would result in a positive impact on engine efficiency, reducing fuel consumption and CO2 emissions.

The current project is aimed at understanding the relationship between microstructure and mechanical performance of this new class of alloys. A particular focus is placed on the high temperature dwell fatigue crack growth behaviour and the micro-mechanisms governing crack advance under such loading and environmental conditions.

Chris Collins - The effect of nitrogen on Ti-6Al-4V

Investigator: Chris Collins, Rolls-Royce plc

Supervisor: Professor David Dye

Collaborators: Professor David Rugg, Rolls-Royce plc

Duration: 01/02/2016 - 01/02/2019 (Part-time MPhil)

Description:

Although the effects of oxygen on titanium alloys have been well characterised; the effects of another alpha stabilising interstitial, nitrogen, have not been researched as throughly. Samples will be taken from bars manufactured in the laboratories at Imperial, with particular care taken over reproducing microstructures and mechanical properties relevant to industrial applications.

This project aims to quantify the effects of a range of nitrogen contamination levels on the general properties of Ti-6Al-4V moving onto study the effects under simple LCF loading.

Name: Peilong Dong

Title: Atmospheric Stress Corrosion Cracking of Low Carbon Austenitic Stainless Steels used in Dry Storage Casks for Interim Storage of Spent Nuclear Fuels.

Supervisor: Dr Mark R Wenman

Collaborator: EDF

Duration: 01/10/2016 – 01/10/2019 (PhD studentship)

Description: One of the major issues with nuclear power generation is the disposal of nuclear waste. In the UK, it has been decided that the ultimate disposal route for high level nuclear waste would be deep geological, however such a facility has not been sited yet and it will be decades before one is constructed and in operation. Previously PWR reactors, for example Sizewell B, used wet storage in the form of fuel ponds, however, these have since reached capacity and alternative methods need to be employed. EDF have decided that further high level waste such as spent nuclear fuels generated at Sizewell B would be stored in austenitic stainless steel dry storage casks.

Austenitic stainless steels are known to fail via a localised corrosion mechanism known as stress corrosion cracking (SCC). In low carbon steels, transgranular SCC may occur when a susceptible material is exposed to a specific chemical environment and a tensile stress. This is an issue as dry store facilities are located coastally (on site of nuclear power stations) exposing canisters to an aggressive chloride atmosphere. Residual tensile stresses will also be present in the canisters due to welding. These conditions make failure by SCC a possibility. However, as these canisters have an expected service time of 50-100 years, it is important to find out the SCC susceptibility and the extent of SCC cracking in these materials as a part of the safety case.

This project looks at the effect of salt deposition and different type of salts (MgCl2, Synthetic Sea-salt, actual sea-salt composition at Sizewell) as well as different compositions of steels (304L, 316L weld material from an actual Holtec MPC canister, and additively manufactured 316L ). Analysis will be done primarily using optical microscopy, SEM, EBSD and EDX for crack counting, grain and texture information, and qualitative chemical analysis. Atom probe tomography will also be used to try and identify the presence and role of chlorine at/ahead of crack tips using atom probe tomography.

Investigator: Dr Claudia Gasparrini

Supervisor: Dr Mark Wenman

Collaborators: Rolls-Royce Plc, Australian Nuclear Science and Technology Organisation, UK Atomic Energy Authority Materials Research Facility, National Nuclear Laboratory, Culham Centre for Fusion Energy, Oxford University, Manchester University, University of New South Wales.

Duration: 01/12/2017 – 01/12/2019 (Postdoctoral Research Associate)

Description: The aim of this project is to investigate the role of microstructure and processing history on the phenomenon of neutron irradiation embrittlement in reactor pressure vessel (RPV) steels. The materials investigated will all be of the same chemical composition of A508 class 3 ferritic steel but manufactured using different methods. There will be forged (in current use), hot isostatically pressed and electron beam welded materials. The position involves help oversee the technical and safety aspects of carrying out irradiations in the OPAL reactor and packaging/transport of the materials to be sent back to the UKAEA Materials Research Facility at Culham. Micro-mechanical tensile testing and microscopy (SEM and TEM) are performed on unirradiated and irradiated steels in collaboration with the UKAEA Materials Research Facility, Manchester University and the Australian Nuclear Science and Technology Organisation.

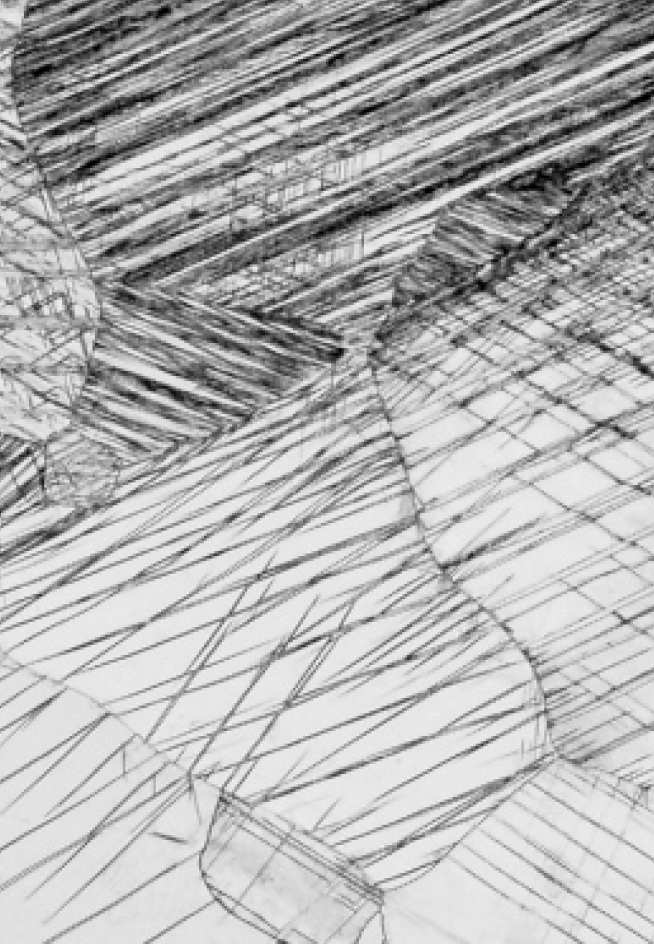

Title: EBSD studies of the evolution of microstructure and damage during the thermal cycling of Pb-free solder materials

Investigator: Tianhong Gu

Supervisors: Dr Ben Britton / Dr Christopher Gourlay

Funding: Self-funded

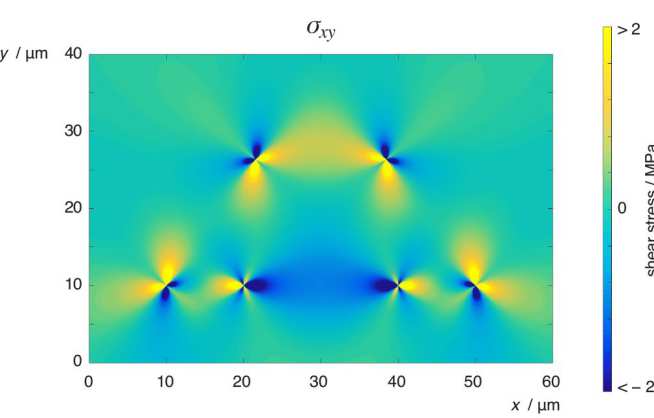

Description: When electronics fail in service the cause is often thermomechanical failure of the solder joints. The major failure is cracking occurred in the bulk near solder / substrate interface, as shown in Figure 1. Pb-free joints usually contain more than 95% tin phase, which has highly anisotropic thermophysical properties. Thus, tin is particularly sensitive to thermomechanical fatigue caused by cycles of heating and cooling. There is a strong industrial demand to understand the mechanisms leading to thermomechanical fatigue failure, to be able to predict the joint microstructure that is most resistant to thermal cycling, and to develop ways of generating the optimum microstructure through alloy design and processing.Therefore, this project will be focused on investigating the role of stress distribution within solder joint generated from thermal expansion mismatch between solder ball and substrate, and microstructure of solder ball on failure mechanisms of solder joints during thermal cycling.

Researcher: Fatos Derguti

Supervisors: Dr Richard J Dashwood, Dr Martin Jackson, Dr David Dye and Professor Malcolm Ward Close (QinetiQ)

Sponsors: EPSRC (Case Studentship), QinetiQ

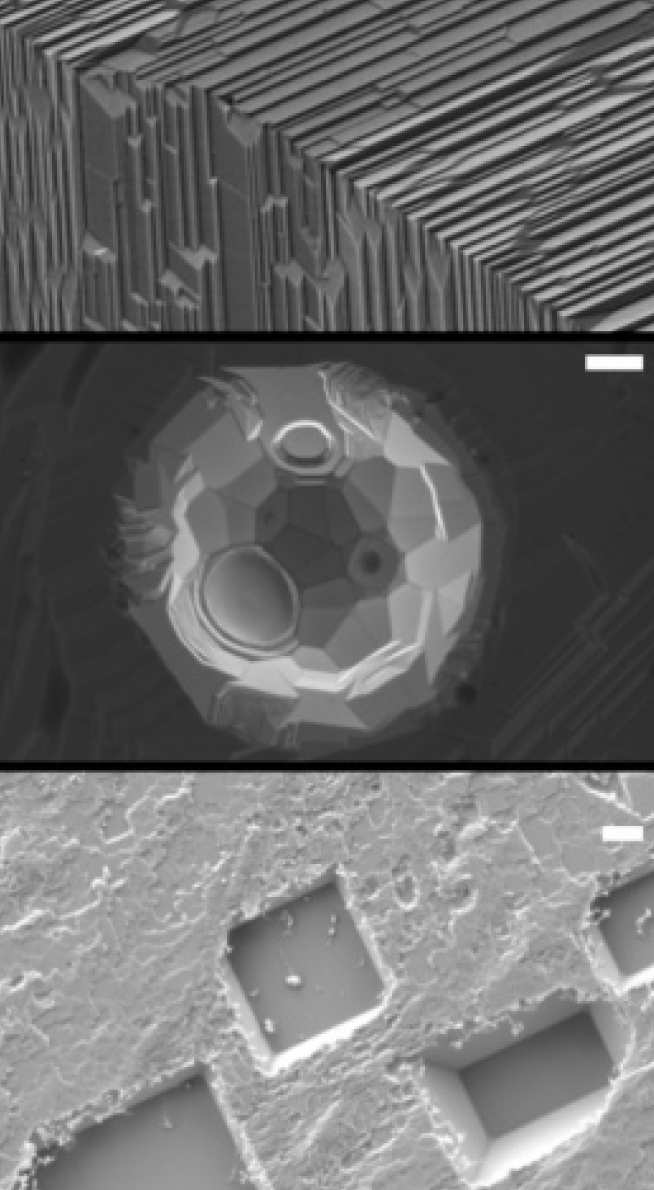

The recent emergence of a number of novel low cost production methods for titanium alloy powders has stimulated significant interest in the near net shape production of titanium components via powder metallurgy. This project is concerned with the development of a new route for titanium parts based on a multi-stage forming and consolidation process using both cold and hot isostatic pressing. Commercial purity titanium and Ti-6Al-4V powders of varying particle size distributions are being cold isostatically pressed at a number of compaction pressures using different bagging materials. The resulting compacts are then being indirectly hot isostatically pressed using a process intended to achieve full material density without the need for expensive metal cans. The importance of the cold isostatic pressing variables and in particular the bagging material, on achieving sufficient green strength for further processing are being investigated. The benefits of this process with respect to the microstructure and properties of the final product are also being evaluated.

Researcher: Stefano Angioletti-Uberti

Supervisors: Professor Peter D Lee and Professor Mike W Finnis

Sponsor: EPSRC (Project Studentship)

This is part of a larger project developing an integrated multiscale modelling framework over the atomistic, defect and continuum length scales relevant to materials with heterogeneous microstructures. Working with researchers at Oxford, Cambridge, Birmingham and the industrial collaborators of Rolls-Royce and Siemens, this project is predicting: liquid state diffusion coefficients and solid-liquid interfacial energies from linked ab initio and molecular dynamics calculations, which will be used to simulate crystal formation during solidification, predicting microstructure, phase and composition using in-house microstructural modelling techniques. The models developed are being coupled into micromechanics models but experimental validation with existing data, and the design of new experiments is a key aspect. The final goal of the overall project is to open up as yet unexplored avenues in materials engineering, leading to true computational materials design.

Calculating Liquid State Thermophysical Properties from First Principles

Researcher: Stefano Angioletti-Uberti

Supervisors: Professor Peter D Lee and Professor Mike W Finnis

Sponsor: EPSRC (Project Studentship)

Modern day single crystal Ni-base superalloy turbine blades suffer from defects arising during solidification (e.g., freckles). These defects may cause premature failure of the blade during service, thus the defective piece must be remelted increasing production costs. Freckle formation depends on preferential partitioning of elements during the solidification process; therefore a knowledge of the partition coefficients is required to engineer alloy compositions and casting procedure to avoid defect formation. Calculation of partition coefficients is possible using atomistic modelling and statistical mechanics. However, the accuracy of the calculated value depends on the reliability of the energetic description of the alloy, and ab-initio modelling is thus the best candidate for this purpose. Lower level approaches based on empirical potentials would be much faster due to their lower computational cost, but do not have the same accuracy. We show here that it is possible to combine both strengths of the two modelling approaches to calculate partition coefficients with an ab-initio accuracy in an efficient way by a free energy perturbation approach. The simulations, made using different embedded atom method potentials, show that it should be effectively possible to apply our technique to ab-initio calculations. This procedure will be applied to actual ab-initio calculations in the near future.

Investigator: Tansel T Arif

Supervisors: Dr Rongshan Qin

Duration: 01/09/2011 - 01/07/2014 (PhD Studentship)

Description:Within the area of materials science there is an increase of interest in modelling techniques that can accurately predict the microstructure of a material subject to various processing conditions. The phase-field method, a popular technique used in this area, has been shown to have the ability to cope with phase transformation dynamics such as solidification and solid-state phase transformations. However, its predictive capabilities apply to a flow free environment where flow effects are minimal compared to other effects. Other techniques such as Smoothed Particle Hydrodynamics (SPH) exist that are more than capable of describing the mechanisms of flow. The aim of this project is to develop a model to describe the evolution of steel from its molten state through to the solid-state phase transformations occurring at lower temperatures. This will be done by developing phase-field models that can deal with displacive transformations as well as diffusive, and SPH models with the ability to be coupled with thermodynamics.

Read more:

Arif TT, Qin RS, A phase-field model for bainitic transformation, Computational Materials Science, 2013, Vol:77, Pages: 230-235

Researcher: Meurig Thomas

Supervisors: Dr Martin Jackson and Professor Trevor C Lindley

Sponsor: EPSRC (Case Studentship), Rolls-Royce plc

Titanium alloys are widely used for manufacture of compressor components for aeroengine gas turbines combining low density with good resistance to creep, fatigue and environmental degradation at elevated temperatures. However, during exposure in oxidising atmospheres at temperatures up to 900 K, inward diffusion of oxygen can result in the formation of an all alpha surface layer. The depth of this surface layer called the alpha case increases with increasing exposure time and temperature. This alpha layer is brittle and mechanical properties can be significantly degraded. This project is improving our understanding of the formation kinetics of alpha case and the subsequent effects on mechanical performance. A parametric study is being carried out to determine the effects of temperature, time, alloy chemistry (i.e., four different alloy classes; CP Ti, IMI 834, Ti-6Al-2Sn-4Zr-6Mo, Ti-10V-2Fe-3Al) and degree of surface deformation (i.e,. intensity of shot peening) prior to thermal treatment. After thermal treatment, a sequence of room temperature tensile loading and high cycle fatigue testing is being applied to 1) determine the nature of crack nucleation/growth and; 2) quantify the cracking size/density in the alpha case and subsurface region. Furthermore, thermal compression loading in conjunction with room temperature tensile straining will be carried out to provide underlining microstructural and cracking information for more complex thermomechanical fatigue investigations and modelling.

Researcher: Appala Naidu Gandhi

Supervisors: Professor Mike W Finnis and Dr David Dye

Sponsor: UKIERI, Imperial College

NiTi-based alloys are the most widely used for their shape-memory properties. These materials have a variety of specialised applications in such diverse fields as dentistry, medicine, and the aerospace industry. Our aim is to develop a theoretical understanding of how to control the temperature of their phase transition by additions of other elements to the basic alloy. The student would use a density functional method for calculating the total energy and phonon frequencies of a number of candidate materials for high temperature shape memory alloys based on NiAl. The energy of plausible crystal structures would be calculated at absolute zero to establish that the model indeed predicts the observed low temperature phase as the most stable, then from the phonon spectra, free energies in the quasiharmonic approximation can be calculated. This will enable phonon frequencies and elastic constants to be calculated as a function of temperature, and any signs of softening, the precursors to a phase transition, will be identified. The systematic effect of additions of impurities such as Pd, Pt, Fe, Cr, Zr and Hf to NiTi alloys are being studied, to elucidate the effect of atomic size, electronic structure and magnetism on the phase transition temperature.

Investigator: Bartosz Barzdajn

Supervisor: Professor Fionn Dunne and Professor Tony Paxton (King's College London)

Collaborators: Rolls-Royce and King's College London

Duration: 03/01/2014 - 28/02/2017 (PhD Studentship)

Description: Structural integrity in austenitic and ferritic steel will be investigated using fundamental materials modelling to further understanding of nucleation, short crack growth, linear elastic fracture mechanics and effects at ferrite interfaces. One focus will be on austenistic to ferritic boundary effects and later interfaces with carbides will be considered. This project will provide a clear methodology to link between quantum effects at the atomistic scale up length and time scales to influence modelling efforts in crystal plasticity modeling.

Investigator: Dr James Coakley

Supervisor: Dr David Dye

Collaborators: Dr John Webster, Rolls-Royce plc

Duration: 24/10/2011 - 23/5/2014 (PDRA)

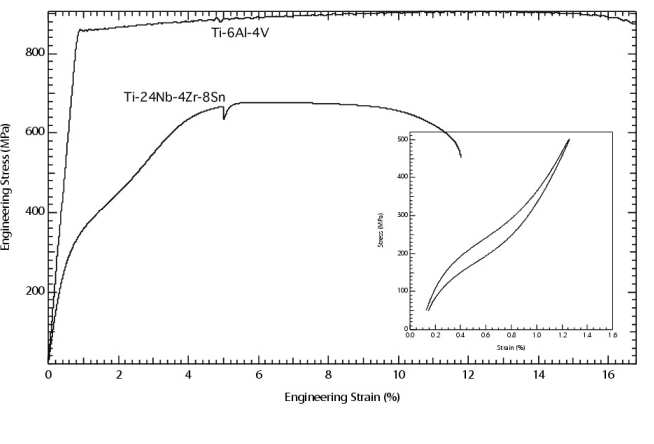

Description:We are developing an understanding of superelastic beta titanium alloys for gas turbine applications. These alloys show remarkable non-linear elastic behaviour, with a very low stiffness and hysteresis in the loading-unloading cycle. Adapting these alloys from more traditional biomedical applications for use in aerospace requires greater knowledge of their performance at elevated temperatures. One focus has been the development of small angle neutron scattering (SANS) for the statistical characterisation of the evolution of 3-50nm precipitates in these alloys, as a complementary technique to 3D atom probe tomography

Researcher: Stefano Angioletti-Uberti

Supervisors: Professor Peter D Lee and Professor Mike W Finnis

Sponsor: EPSRC (Project Studentship)

This is part of a larger project developing an integrated multiscale modelling framework over the atomistic, defect and continuum length scales relevant to materials with heterogeneous microstructures. Working with researchers at Oxford, Cambridge, Birmingham and the industrial collaborators of Rolls-Royce and Siemens, this project is predicting: liquid state diffusion coefficients and solid-liquid interfacial energies from linked ab initio and molecular dynamics calculations, which will be used to simulate crystal formation during solidification, predicting microstructure, phase and composition using in-house microstructural modelling techniques. The models developed are being coupled into micromechanics models but experimental validation with existing data, and the design of new experiments is a key aspect. The final goal of the overall project is to open up as yet unexplored avenues in materials engineering, leading to true computational materials design

Calculating Liquid State Thermophysical Properties from First Principles

Researcher: Stefano Angioletti-Uberti

Supervisors: Professor Peter D Lee and Professor Mike W Finnis

Sponsor: EPSRC (Project Studentship)

Modern day single crystal Ni-base superalloy turbine blades suffer from defects arising during solidification (e.g., freckles). These defects may cause premature failure of the blade during service, thus the defective piece must be remelted increasing production costs. Freckle formation depends on preferential partitioning of elements during the solidification process; therefore a knowledge of the partition coefficients is required to engineer alloy compositions and casting procedure to avoid defect formation. Calculation of partition coefficients is possible using atomistic modelling and statistical mechanics. However, the accuracy of the calculated value depends on the reliability of the energetic description of the alloy, and ab-initio modelling is thus the best candidate for this purpose. Lower level approaches based on empirical potentials would be much faster due to their lower computational cost, but do not have the same accuracy. We show here that it is possible to combine both strengths of the two modelling approaches to calculate partition coefficients with an ab-initio accuracy in an efficient way by a free energy perturbation approach. The simulations, made using different embedded atom method potentials, show that it should be effectively possible to apply our technique to ab-initio calculations. This procedure will be applied to actual ab-initio calculations in the near future.

Investigator: Patrick A Burr

Supervisors: Professor Robin Grimes and Dr Mark Wenman

Collaborators: Australian Nuclear Science and Technology Organisation (ANSTO)

Duration: 01/04/2012 - 01/05/2015 (PhD Studentship - ANSTO and EPSRC)

Description:The project investigates by means of atomic scale modelling, the role of intermetallic second phase particles found in Zr and Be alloys. Zr is used as nuclear fuel cladding in water cooled nuclear fission reactors, while Be alloys have been adopted as plasma facing material in current and future fusion tokamak reactors, as well as high-speed aerospace applications. In particular, the interaction of the intermetallic with H, He, and other impurities is investigated, as these degrade the performance of the alloy. Ultimately the aim is to predict new improved alloys with greater safety margins and longer life cycles.

Read more:

- P.A. Burr, S.T. Murphy, S.C. Lumley, M.R. Wenman, R.W. Grimes, Corrosion Science 69 (2013) 1–4.

- P. A. Burr, S.T. Murphy, S.C. Lumley, M.R. Wenman, R.W. Grimes, Journal of Nuclear Materials (2013), in press.

First author publications:

1. Burr PA, Wenman MR, Gault B, et al. From solid solution to cluster formation of Fe and Cr in α-Zr. Submitt to Acta Mater. 2015.

2. Burr PA, Middleburgh SC, Grimes RW. Crystal structure, thermodynamics, magnetics and disorder properties of Be–Fe–Al intermetallics. J Alloys Compd. 2015;639:111–122. doi:10.1016/j.jallcom.2015.03.101.

3. Burr PA, Murphy ST, Lumley SC, Wenman MR, Grimes RW. Hydrogen accommodation in Zr second phase particles: Implications for H pick-up and hydriding of Zircaloy-2 and Zircaloy-4. Corros Sci. 2013;69:1–4. doi:10.1016/j.corsci.2012.11.036.

4. Burr PA, Murphy ST, Lumley SC, Wenman MR, Grimes RW. Hydrogen solubility in zirconium intermetallic second phase particles. J Nucl Mater. 2013;443(1-3):502–506. doi:10.1016/j.jnucmat.2013.07.060.

Other publications:

5. Horlait D, Grasso S, Al Nasiri N, Burr Pa, Lee, We. Synthesis and oxidation testing of MAX phases composites in the Cr-Ti-Al-C quaternary system, J Am Ceram Soc. In press.

6. Lumley SC, Murphy ST, Burr PA, Grimes RW, Chard-Tuckey PR, Wenman MR. The stability of alloying additions in Zirconium. J Nucl Mater. 2013;437(1-3):122–129. doi:10.1016/j.jnucmat.2013.01.335.

7. Middleburgh SC, Karatchevtseva I, Kennedy BJ, et al. Peroxide defect formation in zirconate perovskites. J Mater Chem A. 2014;2(38):15885–15888. doi:10.1039/C4TA02558J.

8. Lumley SC, Grimes RW, Murphy ST, et al. The thermodynamics of hydride precipitation: The importance of entropy, enthalpy and disorder. Acta Mater. 2014;79:351–362. doi:10.1016/j.actamat.2014.07.019.

9. Middleburgh SC, Burr P a., King DJM, Edwards L, Lumpkin GR, Grimes RW. Structural stability and fission product behaviour in U3Si. J Nucl Mater. 2015. doi:10.1016/j.jnucmat.2015.04.052.

Non peer-reviewed:

10. Rushton MJD, Wenman MR, Mella R, Burr PA. Providing skilled graduates to the nuclear industry. Nucl Futur. 2013;9(1):44.

Investigator: Dr Gaofeng Tian

Supervisor: Dr Barbara Shollock and Professor Fionn Dunne

Collaborators: Dr Jun Jiang

Duration:01/05/2013 - 30/04/2015

Description: Gamma prime precipitates are important strengthening phase in nickel-based superalloy, its microstructural characteristics has an important influence on the mechanical properties. The main aim of the project is to investigate the evolution of gamma prime microstructures or gamma/gamma prime micromechanical properties in the alloy under the different heat treatment conditions and develop models for mechanical behaviour of the evolving gamma prime precipitates in service.

Investigator: Tamara Chapman

Supervisors: Dr David Dye and Professor Trevor Lindley

Collaborators: Dr. Adrian Walker, Prof. David Rugg and Dr Edward Saunders, Rolls-Royce plc

Duration: 01/10/2011 - 30/9/2014 (PhD Studentship)

Description:The occurrence of low life surface initiated fatigue cracks in Ti-6Al-2Sn-4Zr-6Mo (Ti-6246) associated with the presence of Cl is investigated. These cracks are typically recognised by the presence of characteristic fractographic discolouration and local variance of fractographic topography. Secondary Ion Mass Spectrometry has been used to identify the characteristic chemical footprint, along with SEM and TEM based EDX. In addition, transmission electron microscopy on samples rem o ved by FIB milling is used to identif y the micro-mechanisms associated with crack initiation.

Researcher: Mohammed Abdul Azeem

Supervisors: Dr David Dye, Dr Richard J Dashwood and Professor Trevor C Lindley

Funding: UKIERI, Imperial College

Shape memory alloys (SMAs) have great potential to replace conventional electro-mechanical and hydraulic actuators in a broad range of applications, particularly in gas turbines. However, the temperature range of the transformations is currently quite restricted and it is of interest to develop SMAs with higher transformation temperatures. In this project, we are collaborating with the Indian Institute of Science, Bangalore to use the combinatorial approach to test a broad range of compositions using synchrotron diffraction and diffusion multiples. In addition, micromechanical and atomistic modelling will be used to develop insight into the alloy design and into the underlying science of the transformations, which are not well understood.

Investigator: Mitch Cuddihy

Supervisors: Professor Fionn Dunne and Dr Daniel Ballint (Mech Eng)

Collaborators: Dr. Adrian Walker, Dr. David Rugg, Rolls-Royce plc

Duration: 10/01/2012 - 30/9/2015 (PhD Studentship)

Description:This research seeks to contribute to the understanding of cold dwell fatigue, an area of critical importance to the aerospace industry due to its impacts on both component lifespan and efficiency. Cold dwell facet fatigue is a significant and problematic failure mode exhibited by certain titanium alloys that are used in key areas of the gas turbine used in aerospace engines. Current work centres on the development of a crystal plasticity finite element model which will be used to inves tigate the eff ects of factors such as macrozone size and porosities near grain boundaries.

Researcher: James Coakley

Supervisors: Dr David Dye and Professor Roger Reed (University of Birmingham)

Sponsors: EPSRC (Industrial Case Studentship), QinetiQ

The aim of the programme is to extend the existing McLean-Dyson-Basoalto creep model to yield an improved treatment in the case of polycrystal nickel superalloy disc alloys. Specifically we wish to account for 1) the effect of multi-modal gamma prime, 2) the effect of misfit stresses and their evolution, 3) a mapping through to athermal yield, so that high stresses can be considered and a consistent approach taken to normal tensile testing, and 4) the effect of grain size. Specialist testing, potentially including synchrotron and/or neutron diffraction, will also be undertaken to validate the relationships proposed.

Investigator: Bernadette Elliott-Bowman

Supervisors: Dr Rongshan Qin

Duration: 01/09/2012 - 31/05/2015 (PhD Studentship)

Description:This project aims to optimise thermomechanical processing methods for the manipulation of microstructure in high carbon steel. The effects of processing on grain size, recrystallisation rate and associated mechanical properties are considered. Deformation and heat treatment of samples is carried out using in-house equipment. Microstructure characterisation is achieved through the use of SEM, TEM, EBSD and FIB analysis. Mechanical properties including Vicker’s hardness, tensile strength and electrical resistivity are also assessed. Ultimately, the information gathered will be used to understand and develop the relationship between processing, microstructure and mechanical properties.

Investigator: Tomiwa Erinosho

Supervisor: Professor Fionn Dunne

Collaborators: Prof A Wilkinson, Prof R Todd, Prof A Cocks and Dr D Collins (University of Oxford) and BMW

Duration: 9/1/2012 - 9/1/2014 (PhD Studentship)

Description:There is evidence to show that biaxially straining steel non-proportionally can result in higher limit strains or conversely, premature failure depending on the strain path followed. Thus, it is imperative to understand the concept of non-proportionality, its relationship with texture and industrially important effects such as material localization and consequent failure in forming processes for high strength steels applied in auto components.

Read more:

Erinsho, T.O. and F.P.E. Dunne, Lattice strain distributions due to elastic distortions and GND development in polycrystals. Journal of the Mechanics and Pysics of Solids. 67(0): p 62-86 (2014)

Erinosho, T.O., A.C.F. Cocks, and F.P.E. Dunne, Texture, hardening and non-proportionality of strain in BCC polycrystal deformation. International Journal of Plasticity. 50(0): p. 170-192. (2013)

Erinosho, T.O., A.C.F. Cocks, and F.P.E. Dunne, Coupled effects of texture, hardening and non-proportionality of strain on ductility in ferritic steel. Computational Materials Science. 80(0): p. 113-122 (2012)

Erinosho, T.O., A.C.F. Cocks, and F.P.E. Dunne, Non-Proportionality of Strain And Coupling Effects on Dislocation Distribution and Ductility in Ferritic Steel Polycrystal. Coupled Problems V (conference proceedings). (2012)

Researcher: Dylan Ness

Supervisor: Professor Peter D Lee

Sponsor: EPSRC (Project Studentship)

This project is part of a larger US-UK collaborative project whose overall aim is to understand and quantify the factors leading to the formation various solidification defects in nickel-base superalloys. This project focuses on the measurement of the critical material properties for compositions corresponding to the melting range of the alloys. This information will be incorporated in numerical models of defect formation and coupled with macroscopic process models to provide guidance on process control to minimise defect formation. This will centre on the latter aspects, specifically the multiscale modelling of investment casting:

- Quantifying and developing appropriate microstructural models that account for the defect formation.

- Integrating these micro-models with macro-process models (e.g., shaped castings, liquid metal processing).

- Quantification of the models and validation of the findings through laboratory, pilot and industrial-scale experiments.

Researcher: Devashish Fuloria

Supervisor: Professor Peter D Lee

Sponsor: Alcoa Incorporated

Aluminium has now exceeded steel in usage in automobiles due to its lightweight and hence improved mileage. However, despite the reduced environmental impact during use, the production of aluminium sheet is both costly and energy intensive. Twin roll casting is a method of directly producing aluminium alloys in near net shape to sheet at a fraction of the energy costs of conventional DC casting/hot rolling. It also requires a fraction of the capital cost. Although sheet can be produced, various defects can arise which limit the range of alloys which can be cast. This project hopes to elucidate the complex mechanisms causing these defects through a combined experimental and computational study. The overall aim of the project is to gain an improved understanding of the deformation of aluminium alloys during their solidification.

Investigator:Peter J. Evans

Supervisor: Dr David Dye

Collaborators: Dr Matthew Thomas and Mr Roger Thomas, TIMET

Duration: 01/10/2012 - 01/10/2015 (PhD Studentship)

Description: Twinning-induced plasticity (TWIP) has been identified as an effective means of improving the strain-hardening rate of beta titanium alloys, making them suitable for applications requiring a high energy-absorptive capacity, such as fan-blade containment and armour. We will optimise these properties under both static and high strain-rate impact conditions, relating composition and phase stability to the mechanical response of metastable beta alloys.

Researcher: Ioannis Bantounas

Supervisors: Dr David Dye and Professor Trevor C Lindley

Sponsor: EPSRC (Project Studentship)

Current developments in thermo-mechanical processing and novel production routes (e.g., electrolytic reduction) offer the opportunity to provide step-change improvements in the performance of advanced materials. However, new alloy and process developments traditionally have taken 10-15 years to deliver into service, which inhibits the adoption of new technologies. Advances in materials modelling offer the possibility of drastically reducing this lead time through the adoption of virtual prototyping applied to qualification testing and for the optimization of processing. The programme is aimed at 1) investigating whether the effect of texture on fatigue performance is mediated by intergranular microstrains or by some other mechanism, 2) predicting the effect of texture on intergranular microstrain accumulation in this system, 3) predicting the extures obtained during deformation processing and 4) deriving a physically reasonable model for the effect of microstrains on fatigue performance. This would then enable the optimisation by deformation processing of the fatigue performance of Ti-6Al-4V components using knowledge of the in-service loading conditions.

Researcher: Rohit Bhagat

Supervisors: Dr Richard J Dashwood, Dr Martin Jackson and Professor Douglas Inman

Sponsor: Defence Advanced Research Projects Agency DARPA)

The Fray-Farthing-Chen (FFC) Cambridge process was initially developed to reduce titanium dioxide directly in molten calcium chloride. It has subsequently been used to produce several other metals and alloys via the reduction of their respective oxides. In the current work the potential of the process to produce titanium based alloys with compositions that are difficult to synthesize conventionally (i.e., Ti-W) is being assessed. Electrochemical predominance diagrams are being used to predict the stable compounds produced during the reduction of mixed oxides and the reduction pathway is being investigated using a series of partial reductions. Initial experiments have shown that reduction entails interaction between the various metal oxides and sub-oxides, solid state diffusion of metallic components and, in some cases, chemical reactions with the molten salt. In all the alloys investigated chemical homogeneity is achieved during reduction even in notoriously slow diffusing systems such as Ti-W. It is postulated that this homogenisation takes place in the oxide phases where diffusion of the solute species is greater than in metallic titanium.

Investigator: Farah Ismail

Supervisors: Dr Barbara Shollock and Professor Trevor Lindley

Duration: 12/11/2012 - 11/11/2016 (PhD Studentship)

Collaborators: Rolls Royce plc

Description: A new class of cobalt based alloys has become possible when the face-center cubic (FCC) structured gamma (γ) Co-solid solution is strengthened with gamma prime (γ’) Co3(Al,W) phase which is an intermetallic compound with an ordered L12 structure. The two phases have similar lattice parameters and therefore a high degree of coherency when γ’ particles are dispersed throughout the γ Cobalt matrix.

The present project is concerned with a further requirement, the development of γ’-strengthened Cobalt based superalloy with sufficient resistance to oxidation at high temperature. Different alloying elements (chromium and nickel) were added to the Co-Al-W ternary alloy in varying amounts and isotopic oxidation experiments at different temperatures were carried out. In isotopic oxidation, a two-stage oxidation experiment is used where 18O- serves as a tracer element during the second stage oxidation. A larger investigation aims is to characterise the oxidation and oxygen transport mechanisms in Co-based superalloys.

Researcher: Kartik Rao

Supervisors: Dr Richard J Dashwood and Professor Douglas Inman

Sponsor: EPSRC (DTA)

This project concerns the study of lower titanium oxides and calcium titanates during electrochemical reduction in molten salt. The oxides and titanates are of special interest owing to their role as reaction intermediaries in the Fray-Farthing-Chen (FFC) process. For the purpose of this study, the lower oxides and titanates are defined as compounds where titanium exists in a lower oxidation state than 4+. While existing work has demonstrated the existence of these phases during the reduction process, several different oxides may coexist together, thus in-situ studies typically deal with composite material. Using homogeneous precursor material, evaluation of individual reduction reactions is possible. The overall aim of this study is to evaluate the reduction process to quantify the relationship between precursor material and reduction parameters. To achieve this goal, the following objectives are targeted: 1) Optimise precursor production to replicate in-situ morphology and chemistry and obtain material of controlled porosity. 2) Develop understanding of reduction mechanisms and sequences

Investigator: Dr Jun Jiang

Supervisor: Professor Fionn Dunne and Dr T Ben Britton

Collaborators: Dr Gaofeng Tian (Aviation Industry Corporation of China) and Prof A Wilkinson (Oxford)

Duration: 7/1/2013 - 7/1/2015 (PDRA)

Description: This project addresses crack nucleation in aerospace alloys under fatigue and creep failure modes. Deformed samples will be characterised using High Resolution EBSD and deformation patterning and crack imitation sites will be linked to microstructure through microstructurally faithful and physically reasonable finite element models.

Read more:

J Jiang, TB Briton, AJ Wilkinson, Evolution of dislocation density distributions in Copper during tensile deformation, Acta Materialia (2013)

J Jiang, TB Briton, AJ Wilkinson, Mapping type III intragranular residual stress distributions in deformed copper polycrystals, Acta Materialia (2013)

TB Briton, J Jiang, PS Karamched, AJ Wilkinson, Probing Deformation and Revealing Microstructural Mechanisms with Cross-Correlation-Based, High-Resolution Electron Backscatter Diffraction, JOM (2013)

Researcher: Konstantinos Alevizos

Supervisors:Dr David Dye, Dr Richard J Dashwood and Dr Martin Jackson

Sponsor: European Union Marie Curie Fellowship

The creep performance of Zr-2.5Nb is a sensitive function of both its texture and microstructure. In this project, model extrusions of Zr-2.5Nb are being performed with the aim of optimising the texture and microstructure to maximise creep performance. An auxilliary programme of Al tube extrusions and isothermal compression testing will be performed. Finite element models will be used to predict the metal flow, adiabatic heating and strain path within the material, and these will be linked to models for the texture and microstructure development.

Investigator: Dr Tea-Sung (Terry) Jun

Supervisors: Dr Ben Britton and Professor Fionn Dunne

Collaborators: Rolls-Royce plc/Timet/Westinghouse/EDF

Duration: 13/01/2014 - 13/01/2016 (PDRA - HexMat)

Description: We will investigate micro-mechanical deformation mechanism of hexagonal polycrystals. These alloys are profoundly important to industries (aero, energy, biomedical, defence sector, etc) for improving our daily-lives. Hexagonal materials have complex internal structures, and hence require detailed experimental characterisation, theoretical description and appropriate prediction models. Samples will be deformed by micro-mechanical testings (e.g., micro-pillar or micro-cantilever) and simultaneously characterised by in-situ EBSD and DIC. Based on the experimentally-obtained deformation behaviour linked to microstructural changes, finite element models will be developed

and compared.

Researcher: Adam M Stapleton

Supervisors: Dr David Dye, Dr Richard J Dashwood and Professor Trevor C Lindley

Sponsors: EPSRC, Rolls-Royce plc

It is thought that crystallographic texture plays a crucial role in mediating the fatigue behaviour of Ti-6Al-4V, possibly through the effects of intergranular microstrain. The project is investigating the way in which load is partitioned between particular orientations and phases during cyclic tensile loading using X-ray and neutron diffraction. An elasto-plastic self consistent (EPSC) model, based upon the notion of an ellipsoidal inclusion interacting with a surrounding homogeneous effective medium (HEM), provides a mathematically rigorous basis for the simulation of mechanical loading in polycrystalline materials. This is used to predict the behaviour and evolution of intergranular microstrains in a polycrystalline material during cyclic loading.

Investigator: Kristina Kareh

Supervisors: Dr. Chris Gourlay and Professor Peter Lee (Manchester)

Collaborators: Dr. R. Atwood (Diamond Synchrotron)

Duration: 1/10/2009 - 30/9/2013 (PhD Studentship)

Description:Mounting evidence points towards metals behaving as cohesionless granular materials when deformed in the semi-solid state, which can lead to large-scale defects due to shear banding in components deformed during solidification. Using fast synchrotron X-ray tomography, the microstructure of globular binary Al-Cu alloys has been imaged during uniaxial compression and extrusion in 3D. By characterising the shape of all crystals i n the specimen, their displacements and interactions are being tracked during deformation with the aim of better understanding mush rheology.

Read more:

K.M. Kareh, P.D. Lee, and C.M. Gourlay. Globule-globule interactions during deformation in semi-solid Al-Cu using time-resolved X-ray tomography. 12th International Conference on Semi-Solid Processing of Alloys and Composites (S2P XII), Cape Town, South Africa 2012.

K.M. Kareh, P.D. Lee, and C.M. Gourlay. In situ, time-resolved tomography for validating models of deformation in semi-solid alloys. 13th Modeling of Casting, Welding and Advanced Solidification Processes 2012 (MCWASP XIII), Schladming, Austria 2012.

Investigator: Chedtha Puncreobutr

Supervisors: Professor Peter Lee (University of Manchester) and Dr Andrew Horsfield

Duration: 01/10/2009 - 30/09/2013 (PhD Studentship)

Collaborators: T. Connolley (DLS), J.L. Fife (SLS), A.B. Phillion (UBC)

![(a) Al-Si-Cu-Fe solidifying microstructure; (b) intermetallics (coloured) and dendrites (light grey) rendered in 3D from an ROI [yellow square in (a)]; (c) CFD simulated velocity field showing how intermetallics block liquid flow.](/media/migration/research-groups/Chedtha_Puncreobutr_re--tojpeg_1441362551915_x2.jpg)

Description:The enrichment of Fe during aluminium recycling enhances the formation of Fe-rich intermetallics, particularly β-Al5FeSi, limiting their usage in many fatigue-sensitive applications. In this project, fast synchrotron x-ray tomography is used to investigate microstructure evolution and defect formation in a commercial Al-Si-Cu-Fe alloy. Novel image analysis techniques as well as coupled computational fluid dynamics provide new insights into the mechanisms of intermetallic nucleation and growth, together with their influence on defect formation. This characterisation of dynamic behaviour then helps design better alloys and applications.

Read more:

C. Puncreobutr, P.D. Lee, R.W. Hamilton, B. Cai, T. Connolley, Synchrotron tomographic characterisation of damage evolution during aluminium alloy solidification. Metallurgical and Materials Transactions A, Online First, 2012.

C. Puncreobutr, P.D. Lee, R.W. Hamilton, A.B. Phillion, Quantitative 3D characterisation of solidification structure and defect evolution in Al alloys. JOM, 64(1), pp.89-95, 2012.

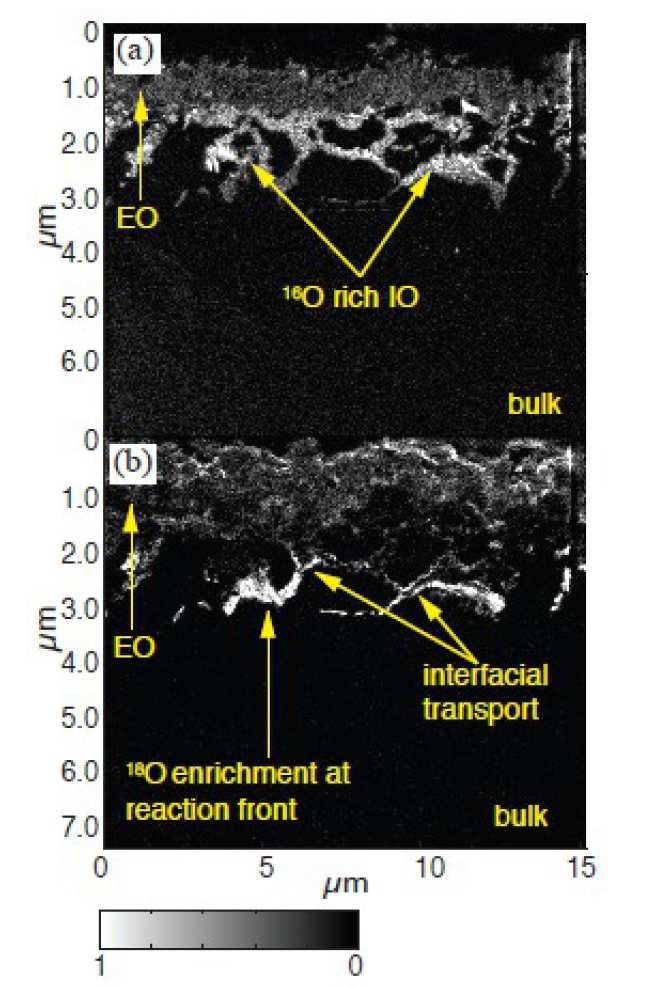

Investigator: Jinesung Jung

Supervisors: Dr. Barbara Shollock and Dr David McPhail

Duration: 01/03/2010 - 31/12/2013 (PhD Studentship)

Description:Single-crystal nickel-base suepralloys are extensively used for blades with thermal barrier coating (TBC) system in gas turbine engine. In the case of the coating failure in service, substrate is directly exposed to corrosive gas environment and is damaged by oxidation. Understanding the oxidation behaviour of bare metal is crucial to improve the performance of the single-crystal nickel-base superalloys. This research focuses on elucidating high temperature oxidation behaviour of CMSX-4 alloy with the doping of lanthanum including the transient oxidation behaviour during heating up with oxygen partial pressure. To do this, two-stage oxidation experiments using isotopic oxygen have been performed and various analyzing methods such as FEG-SEM, TEM with EDX, FIB-SEM, and ToF-SIMS have been applied.

Investigator: Matthias Knop

Supervisor: Dr David Dye

Collaborators: Rolls Royce plc

Duration: 04/07/2011 - 03/07/2014 (PhD Studentship)

Description: The aim of this project is to find an alternative to the established Ni-base superalloys for the hot section of turbine engines. Co-base alloys may be an suitable alternative because of their higher melting point and better corrosion resistance. This leads to an increase of the service temperature to increase the fuel efficiency and therefore reducing cost and CO2-emissions. In 2006, Sato et al. discovered a phase in Co-base alloys which improves their high temperature strength significantly. Alloy candidates with a desired microstructure and oxidation resistance will be developed and mechanically tested to evaluate their viability.

Researcher: Despina Hadjiapostolidou

Supervisor: Dr Barbara A Shollock

Sponsors: EPSRC (Responsive Mode Studentship), Rolls-Royce plc, RWE NPower

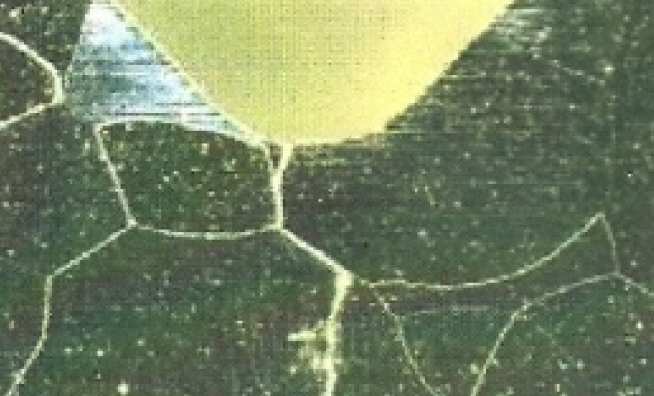

The nickel-base superalloys used in gas turbines face one of the most challenging conditions of any material. Used at high temperatures and stresses, these alloys must maintain their strength despite microstructural changes. The mechanical properties of these alloys are determined by the precipitation of γ' phase in the γ matrix; the properties are affected by the size, shape and distribution of these γ' precipitates. This project investigates the effect of long-term aging (up to 20,000 hours, 800C to 1050C) on the coarsening of γ' precipitates in René 80, a polycrystalline Ni-base cast superalloy. Long term exposure is especially important for gas turbines used in the power generation industry as these turbines operate continuously for extended periods. It has been found that coarsening continues even after long term exposure, contrary to the popularly accepted idea that coarsening does not continue past about 1000h.

The oxidation and nitridation of the material after long term aging is being investigated. After long times at temperature, significant degradation of the surface and subsurface of the alloy occurs by internal nitridation and oxidation. TEM and XRD have been used to identify the complex phase formed and a model for the process is being developed.

Researcher: Zohaib Malik

Supervisors: Professor Peter D Lee and Dr R Lowe (National Physical Laboratory)

Funding: EPSRC (Industrial Case), NPL

This project is explaining the melt behaviour of metal-carbon binary eutectic alloys with melt temperatures up to 2500C. These alloys are attracting increasing interest as reference standards based on their eutectic temperature. It is expected they will be formally accepted as standards following the proposed redefinition of the kelvin in ~2012. We are applying and developing of improved macroscopic and microscopic models of diffusion in eutectic alloys. These are being validated against experimental melt data and assessed microstructure. The relative importance of microstructure, impurities and thermal environment will be assessed.

Researcher: Pavel E Ramirez Lopez

Supervisors: Professor Peter D Lee and Professor Kenneth C Mills

Sponsor: National Council of Science and Technology (CONACYT), Mexico

Quality control of the Continuous Casting Machine is difficult due to the variety of physical phenomena occurring simultaneously in the casting process. These phenomena include heat transfer, metal flow dynamics and solidification. The combination of all these factors produces a complex process where the alteration of one variable has deep impact in the rest and finally, in the quality of the product. This project is gaining an understanding of the physical phenomena taking place inside the mould. Therefore, the effects of the principal casting variables in the whole process are analysed and quantified. Once these fundamentals are fully understood, it is possible to predict optimal casting conditions for a defect free practice. The analysis is based on a numerical model capable of coupling metal flow dynamics, heat transfer and solidification inside the mould. The multiphase system (molten steel-slag-air-argon) and the stress accumulation in the shell are being modelled to provide a realistic representation of the process. Slag composition and physical properties are also included to determine their influence on lubrication and defect formation.

Researcher: Sobhan Abolghasemi

Supervisors: Professor Peter D Lee and Professor Trevor Lindley

Sponsor: EPSRC (DTA)

Flare tips are part of an oil and gas platform's essential safety system, allowing for the safe disposal of hydrocarbons in the event of an emergency. Flare systems are increasingly operated at low gas flow rates to meet environmental regulations; an operating regime that increases the time that the flame impinges on the tip, thus increasing its operating temperature and decreasing the lifetime. Extending flare tip life will have a significant impact on both safety and maintenance costs. A potential failure involves a material degradation process based on a high temperature creep-fatigue-oxidation interactive mechanism which is thought to promote local grain boundary embrittlement of the metallic alloys. A Thermomechanical Index of alloy behaviour is being developed to optimise the selection of alloys for potential flare tip use. Flare tip metal temperaturesare measured using thermo-imaging techniques. Knowledge of the actual operating temperature range will allow a more robust analysis of the alloy behaviour by removing the simplifying assumptions that have been made to date. The thermo-mechanical models will be extended to include local embrittlement processes, including the role of oxidation behaviour (particularly at grain boundaries), processes that are presently poorly understood. The kinetics of high temperature oxidation of Inconel 625, the 700 series and other alloys designed for high temperature oxidation resistance will be studied using optical and electron microscopic techniques. An understanding the materials issues involved and a development of improved solutions will enable platform operators to develop a risk-based inspection strategy for flare tips.

Investigator: Wenjun Lu

Supervisors: Dr Rongshan Qin and Professor Jianguo Lin (Mech Eng)

Duration: 01/10/2012 - 30/09/2015 (PhD Studentship)

Description: Processing conditions are designed for fabrication of novel microstructures. Thermodynamics, kinetics for phase transition and heat/mass transfers are considered. Optical microscope, SEM, EBSD, XRD are applied to characterize the microstructures. Mechanical properties (e.g. Vickers hardness, tensile strength, ...) of the samples are measured. Several steels are examined to provide the design principles.

Investigator: Benjamin Foss

Supervisors: Dr. David McPhail and Dr. Barbara Shollock

Duration: 01/10/2010 - 01/11/2013 (PhD Studentship - EPSRC/Rolls-Royce plc)

Collaborators: Rolls-Royce plc

Description:The current demands of the aviation industry for increased gas-turbine efficiency pushes Ni-based superalloys used for turbine discs to their operational limits. Throughout the disc’s service life, it is important that the mechanical integrity is maintained. This drive for improved efficiency necessitates higher turbine entry temperatures, requiring that alloys used exhibit superior oxidation resistance. The synergistic effects of oxidation and high mechanical stresses pose an even greater problem and can be responsible for a reduction in the fatigue life of these components. My work investigates the role of oxidation and oxygen transport during high-temperature exposure of an advanced powder metallurgy Ni-based superalloy currently used in the latest of gas turbines. Specifically, experiments have developed and adopted the use of isotopic tracing protocols in combination with Focused Ion Beam Secondary Ion Mass Spectrometry (FIB-SIMS) to characterise oxygen transport. In contrast to conventional SIMS by either mass spectrometry or depth profiling, FIB-SIMS offers the opportunity to produce elemental maps with excellent lateral resolution.

Read more:

B. J. Foss, S. Gray, M.C. Hardy, S. Stekovic, D. S. McPhail, B. A. Shollock,; Analysis of shot-‐peening and residual stress relaxation in the nickel-‐based superalloy RR1000.; Acta Materialia, 61, 7, 2458-‐2559 (2013).

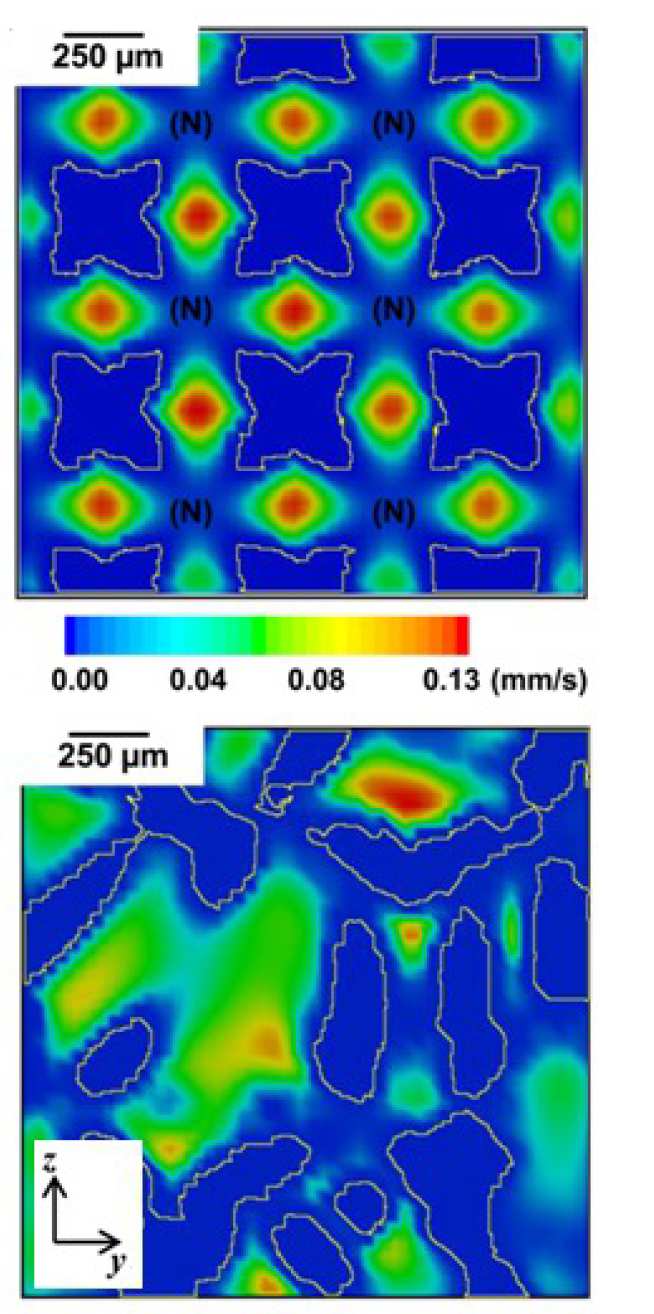

Investigator: Ziyu (Flora) Zhang

Supervisors: Dr Julian Jones and Prof Peter Lee (Manchester)

Duration: 01/10/2009 - 01/08/2013 (PhD Studentship)

Collaborators: Stryker Orthopaedics

Description:Titanium (Ti) porous foams produced by additive manufacturing (AM) techniques are promising for fixation devices in orthopaedic applications. These implants should possess sufficient permeability to allow vascular invasion, integration with the host tissue and also satisfy the transport requirements of remodelling bone. The mechanical properties of implants should also match those of the host tissue to ensure sufficient life span in the body. Both macro and micro-structures of implants influence the mechanical and flow properties. Techniques are therefore needed to characterise the structural parameters and to evaluate their effects on the performance of the implant. This project focuses on computational modelling tools based on X-ray microtomography (µCT) images to characterise the flow and mechanical properties of porous foams. The aim of the study is to develop and apply these tools on Ti implants with different structures to investigate how the design variables offered by AM technique can be used to alter the implant architecture on multiple length scales to control and tailor the flow and mechanical properties.

Read more:

Zhang, Z., Jones, D., Yue, S., Lee, P.D., Jones, J.R., Sutcliffe,, C.J., Jones, E., “Hierarchical tailoring of strut architecture to control permeability of additive manufactured titanium implants”, Mat. Sci. Eng. C, 33 (7), pp4055–62, 2013

Investigator: Paul Mulvey

Supervisor : Dr David Dye

Duration: 01/07/2013 - 30/06/2016 (PhD Studentship - EPSRC)

Collaborators: Rolls Royce plc.

Description: Next generation superalloys based on the Co-Al-W system are being developed to produce strong, oxidation resistant alloys to replace the out-dated Ni-based superalloys currently used in gas turbine applications. Co-based alloys have the potential to offer superior corrosion resistance and higher melting points compared to the current Ni-based alloys, resulting in the ability to design higher turbine entry temperatures. This project will investigate the new ternary Co3(Al,W) phase, its deformation mechanisms and the effects of heat treatment on the microstructure, with particular focus on the role of carbide formation. Analysis techniques will include TEM, FIB, EBSD and synchrotron X-ray diffraction.

Researcher: Peter J Smith

Supervisors: Professor Alan Atkinson and Professor MG (Gwyn) Hocking

Sponsors: Crown Technology, Wantage (PRI Scheme)

During the past 15 years the processed food can sector of the Metal Packaging Industry has experienced a significant incidence of environmental stress cracking failures in metal containers having either tinplate or electro chrome coated steel components. The time to failure has varied significantly from less than one year following packing to three years or more. Despite investigations by can makers and steel suppliers, published work does not provide a comprehensive understanding of the problem to enable preventative measures to be implemented, which are both effective and economic. The present study is gaining a better understanding of risk factors and potential means to reduce risks. Two main container types are being examined: three-piece round and two-piece drawn and redrawn containers. Both container types show susceptibility to environmental stress cracking failures at the more heavily worked areas of the bodies and or ends.

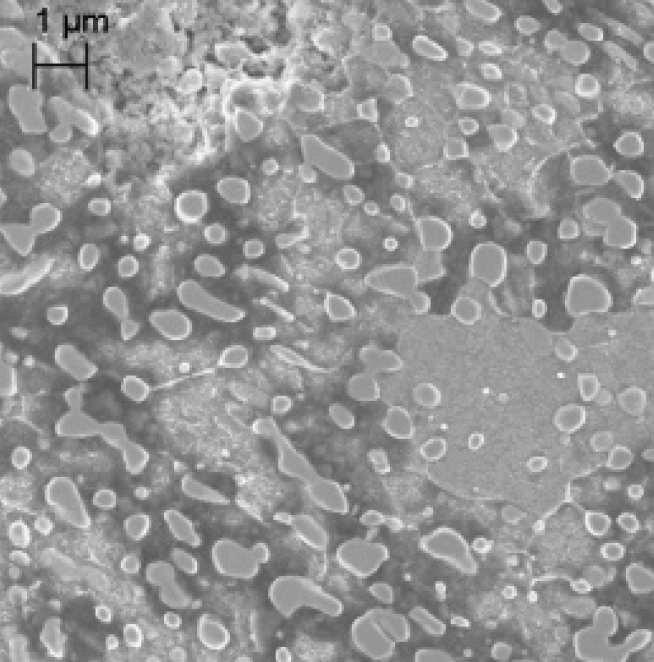

Investigator: Dr Maelig Ollivier

Supervisors: Dr Chris Gourlay

Collaborators: AWE

Duration: 01/02/2014 - 31/1/2016

Description: If heated to high temperatures, silver surfaces undergo pronounced morphological surface changes: a process known as "thermal etching" which includes surface roughening, the formation of striations, faceting, grooving and etch pitting. These different phenomena are influenced by a large set of parameters, such as temperature, time, the atmosphere surrounding silver or contact material and contact pressure. The aim of this project is to better understand the formation of sub-micron to micron sized features on the surface of silver and to study the link between the surface changes and the extrinsic parameters applied to the material.

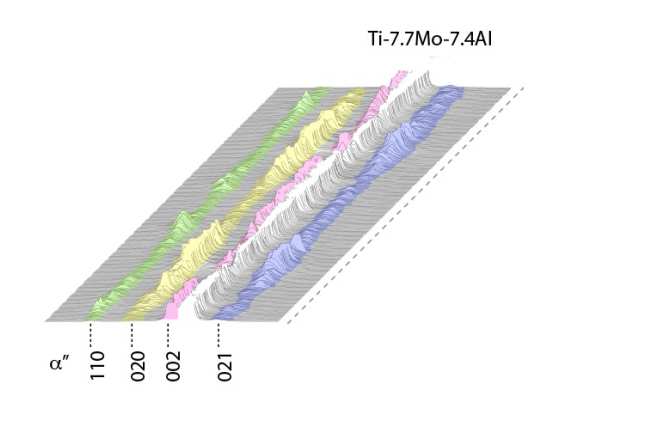

Investigator: Oliver Joris

Supervisor: Dr David Dye

Collaborators: Dr. Adrian Walker, Prof. David Rugg and Dr Edward Saunders, Rolls-Royce plc

Duration: 1/9/2010 - 23/12/2013 (PhD Studentship)

Description:Beta titanium alloys can be used in both biomedical and energy absorption applications due to their low modulus and energy absorption capabilities. Key to this is the superelastic property, where there is a stress induced fully recoverable phase transformation. In this work, we are examining the effect of beta stability (Mo and Al content) and O content (stress to induce the phase transformation and reversibility). We will use a variety of techniques, including the high energy JEEP X-ray beamline at the Diamond Light Source. Here we are exploring the phase transformation using in-situ ther momechanical testing. This will be combined with laboratory studies, including T EM to study fine scale microstructure features and phases present.

Investigator: Dr Daniela Proprentner

Supervisor: Dr Barbara Shollock

Duration: 06/20/2013 - 07/19/2015 (PDRA - EPSRC funded)

Collaborators: Loughborough University, University of Southampton, Alstom, DSTL, E.ON, NASA

Description: Nickel-based alloys are widely used in power generation, nuclear and aerospace industries due to their superior mechanical properties at high temperature. As structural materials these alloys require a strong resistance to crack initiation and propagation for safe-life design and assessment of their components. At elevated temperature crack growth rates in such alloys exposed to air can be drastically accelerated, by two and even three orders of magnitude, due to the attack of oxidation. This research will investigate the physical process of oxidation damage at a crack tip and crack growth providing direct insight into oxidation-embrittlement phenomenon at crack tip under fatigue-oxidation conditions in controlled environments (vacuum, air, oxygen-18).

- Fundamentals of Deformation and Cracking in Zirconium Alloys

- Generation of Ultra-fine Grained Microstructures via Multiple Extrusions

- Micromechanical Modelling of the Forging of Titanium Alloys

- Micromechanics and Phase Transformations in Welded Steel Joints

- Micromechanical Modelling of the Forging of Titanium Alloys

- Micromechanics and Phase Transformations in Welded Steel Joints

- Optimisation of the FFC Cambridge Process for Processing of NiTi

- Porosity Formation in Aluminium Alloys: In-situ Observation and Mesoscale Simulation

- Production and Charaterisation of Metal Foams

- TBC Surface Chemical Contamination on Service-retrieved Industrial Gas Turbine Engines

- Thermomechanical Processing of Near Beta Titanium Alloy 5al-5V-5Mo-3cr

- Thermomechanical Processing of Titanium Matrix Composites

- Ti-64 Deformation

Investigator: Khandaker M Rahman

Supervisors: Dr David Dye

Duration: 05/10/2009 - 30/09/2013 (PhD Studentship)

Collaborators: DSTL, Tata Steel

Description:TWinning Induced Plasticity (TWIP) steels are single phase austenitic alloys that successfully combine the properties of high strength and ductility. TWIP steels are an ideal candidate material for applications where the absorption of energy is required, such as armour or automotive crash safety systems. The TWIP effect arises due to the formation of thin lenticular deformation twins during straining. These twins act as strong barriers to dislocation movement. This results in a dynamic grain refinement process, leading to an increasing work hardening capacity and superior ductility. In this study we aim to better understand the mechanical properties of the material and the twinning process. This is achieved using a range of techniques including in-situ X-ray synchrotron diffraction, high strain rate Hopkinson bar and blast testing and self-consistent modelling. The results will then be augmented using a range of microscopy techniques.

Investigator: Anna Radecka

Supervisor: Dr David Dye and Professor Trevor Lindley

Collaborators: Professor David Rugg, Rolls-Royce plc

Duration: 01/10/2012 - 30/09/2015 (PhD Studentship)

Description: It is well documented that cracks and defects develop under safe load, often as result of fatigue. A better understanding of the fatigue-cracking behaviour of titanium alloys is a key challenge if we are to ensure the long-term reliability of jet engine components. We need to develop an accurate method for the estimation of the fatigue life of a component and a necessary prerequisite will be to identify the plastic deformation process leading to fatigue cracking. The aim of the project is to determine how ordering of aluminium atoms can affect the extent of planar slip in alpha grains occurring during the plastic deformation in alpha-titanium alloys. The degree of planar slip can be linked to fatigue performance.

Investigator: Alireza Rahnama

Supervisors: Dr Rongshan Qin

Duration: 01/10/2010 - 01/10/2013 (PhD Studentship)

Description:This project is both computational and experimental in nature. A 3D model using a new computational method for phase transitions in the thermomechanical processing of strong steels has been developed. The model includes the thermomechanical processing conditions (TMPC) and property relationships of strong steels that will be applied in the automobile industry. In the experimental part, a novel microstructure in transformation-induced plasticity (TRIP) steel has been developed by the application of innovative electropulsing technique (EP). Mechanical properties and microstructure have been investigated by a number of techniques including optical microscope, TEM, XRD, SEM and mechanical testing.

Investigator: Ananthi Sankaran

Supervisors: Dr David Dye

Collaborators: Rolls-Royce plc.

Duration: 27/10/2012 - 30/09/2014 (PDRA)

Description: The current research addresses the mechanisms responsible for the plastic deformation and cracking in Zircaloy-4. Zircaloy-4 is regularly used in pressurised water reactors. They are subjected to High Cycle Fatigue (HCP) as a result of fluctuating temperatures and vibrational loading in service. To address this problem HCF tests were performed on a recrystallised Zircaloy-4. A combination of Quantitative Tilt Fractography and Electron BackScatter Diffraction (EBSD) is used to determine the spatial and crystallographic orientation of the fracture facets at the initiation site. Transmission Electron Microscopy (TEM) is used to determine the deformation mechanisms and dislocation motions along specific slip systems.

Investigator: Peter Tympel

Supervisor: Dr. David Dye and Professor Trevor Lindley

Collaborators: Mark Dixon and Edward A Saunders, Rolls-Royce plc.

Duration: 01/10/2012 - 9/30/2015 (PhD Studentship)

Description: Titanium alloys are used widespread in aero jet engines as disk and fan blade material. In flight the components experience tensile stresses due to the high rotation speed of the turbine. The stress reaches its maximum value during the climb of the plane and is reduced when it is cruising. In terms of fatigue, one flight consists of periods with constant high stresses (dwell) and cyclic loadings at lower stresses. Traditionally fatigue experiments are carried out at either pure dwell or cyclic loading condition but are rarely combined. It is little known about the interaction of different fatigue regimes, which are present in real service. The objective is to characterize the initiation and propagation of fatigue cracks under consideration of the microstructure, microtexture and combined loading conditions. The spectrum of employed methods ranges from fractography, EBSD analysis to TEM.

Investigator: Victor Wan

Supervisor: Professor Fionn Dunne

Collaborators: Dr Duncan Maclachlan / Rolls Royce Lifing and Methods Group

Duration: 01/10/2013 - 31/03/2016

Description:This PhD research is to address modelling techniques at the single crystal length scale within polycrystalline nickel alloys for fatigue crack nucleation and growth up to the crack length at which continuum assumptions become reasonable. Initial work is to address crack nucleation fatigue indicator parameters (FIPs) at the grain level but within polycrystal aggregates, through to the development of micro-cracking within a single grain. The full anisotropic nature of both elasticity and slip at the crystallographic level are to be addressed in the context of fracture toughness measures. The work is to further consider crack growth but within a single grain, taking full account of the anisotropy, and to address the appropriate computational tools within a crystal plasticity finite element context. Concerns of crack transfer across a grain boundary and subsequent growth through multiple grains will also be taken into account up to the circumstances at which conventional growth laws become applicable.

Investigator: Hannah Weekes

Supervisors: Dr David Dye and Professor Trevor Lindley

Collaborators: Dr. David Rugg (Rolls-Royce)

Duration: 3/10/2011 - 3/10/2014 (PhD Studentship - Rolls-Royce/EPSRC)

Description: Zirconium alloys are continually being used throughout the nuclear industry due to their high performance under severe pressure and temperature conditions, coupled with their low thermal neutron absorption cross-section and high corrosion resistance in aqueous environments. However, high levels of hydrogen absorption during service have been found to result in the generation of detrimental hydride precipitation weakening the alloy integrity - a key issue when considering reactor storage post-service. This project incorporates extensive in-situ synchrotron work, including micro-beam Laue indentation on hydride containing micropillars in order to further our understanding of deformation characteristics, as well as x-ray diffraction experiments regarding a) high pressure deformation of hydrided zirconium alloys and b) hydride reorientation due to the application of a tensile stress. Coupled with ex-situ low cycle fatigue testing, this matrix of work aims to further our understanding of the micro-mechanical behaviour of hydride containing zirconium alloys.

Investigator: Tiantian Zhang

Supervisors: Dr Barbara Shollock and Professor Fionn Dunne

Collaborators: Dr Mark Hardy, Rolls-Royce plc

Duration: 10/01/2012 - 12/31/2015 (PhD Studentship)

Description: The aim of the project is to develop a crystal plasticity model that describes the nucleation of fatigue cracks in a powder metallurgy nickel base superalloy (RR1000). The nature of the inclusions and their local effect on the matrix (to include grain size and orientation and local strain) will be determined experimentally using electron microscopy. In addition, the inclusion/matrix interface will be studied. These experiments will be used to develop and validate finite element modelling approaches.

Investigator: Dr Xinfang Zhang

Supervisors: Dr Rongshan Qin

Duration: 14/10/2012 - 13/10/2015 (PDRA)

Description:The project aims to develop a novel clean steel green processing method for the production of super clean steel with significantly reduced energy cost. The microstructure are observed by optical microscope, SEM, TEM, and XRD. The theory of thermodynamics and kinetics are considered to design the clean steel green process. The mechanical properties are performed to confirm the cleanliness of the steel.

Read more:

Zhang XF, Lu WJ, Qin RS, Removal of MnS inclusions in molten steel using electropulsing. Scripta Materialia, 2013, Vol. 69, Pages: 453-456.

Investigator: Zebang Zheng

Supervisor : Professor Fionn Dunne and Dr Daniel Balint (Mech Eng)

Duration: 01/10/2012 - 31/12/2016 (MSc + PhD Studentship)

Description: This project will link high fidelity crystal plasticity (CP) modelling with discreet dislocation dynamics (DD) to model micro-deformation by slip in a grain boundary region. This approach will be used to address the stress states in grain boundary regions, with constitutive CP laws derived from DD models, thought to cause problems during cold dwell fatigue in Ti alloys.

Title: Design and development of new materials for gas turbines – high strength titanium alloys

Investigator: Dr. Alexander (Sandy) Knowles

Supervisors: Prof. D. Dye

Duration: Oct 2015–present DARE (www.darealloys.org) PDRA, Oct 2016–17 EPSRC Doctoral Prize Fellow

Description: Design and development of new materials for gas turbines as part of the EPSRC ‘Designing alloys for resource efficiency (DARE) - a manufacturing approach’ partnership across the University of Sheffield, Imperial College London, Kings College London and the University of Cambridge as well as ten industrial partners, including: TIMET, Rolls-Royce, Tata Steel, Siemens and Magnesium Elektron.

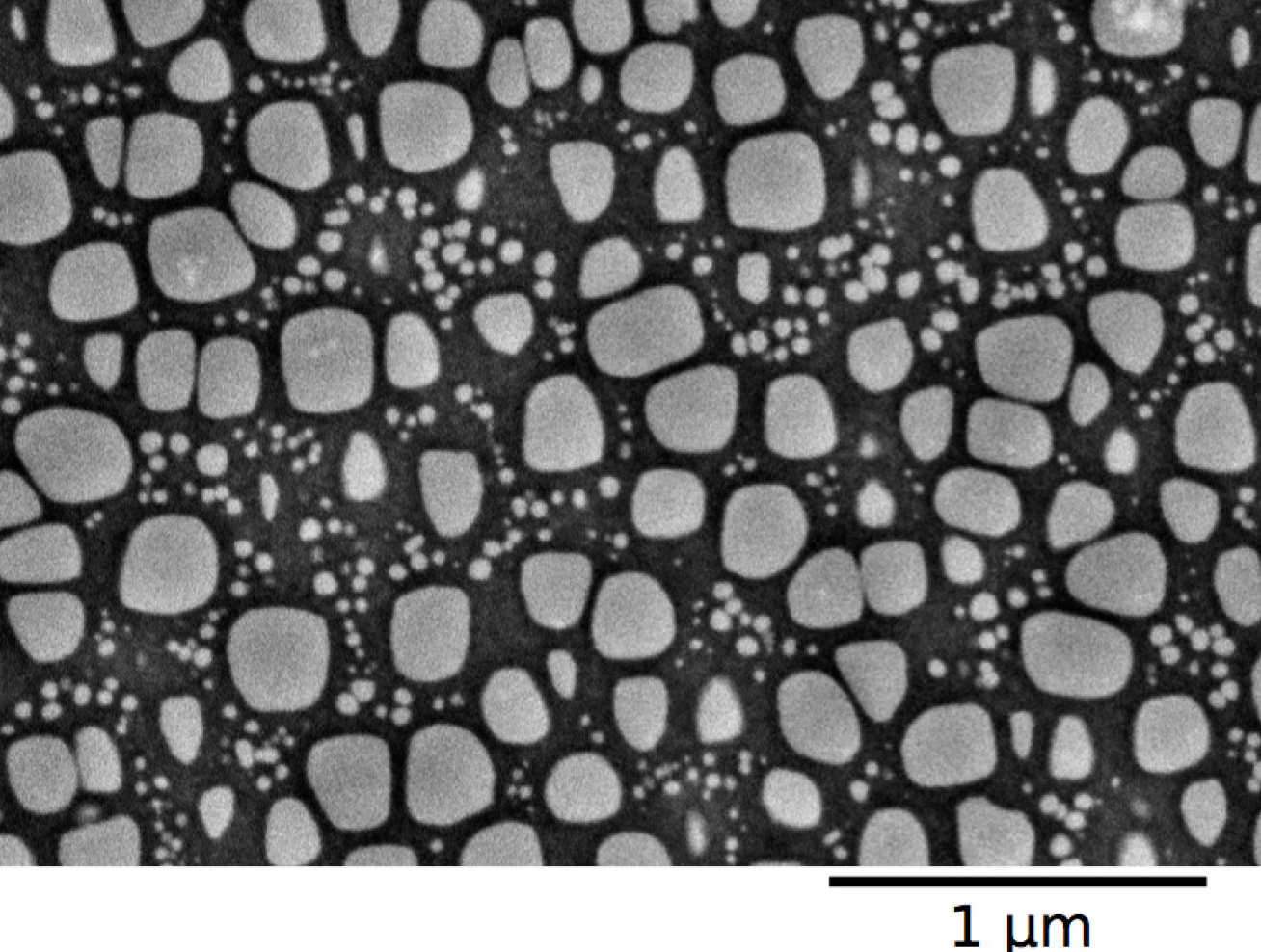

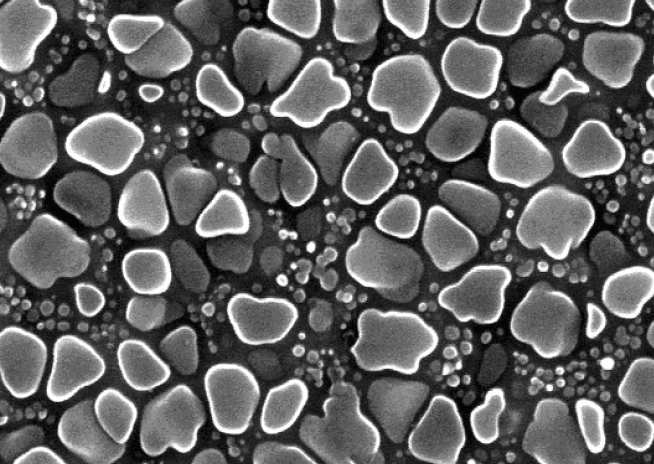

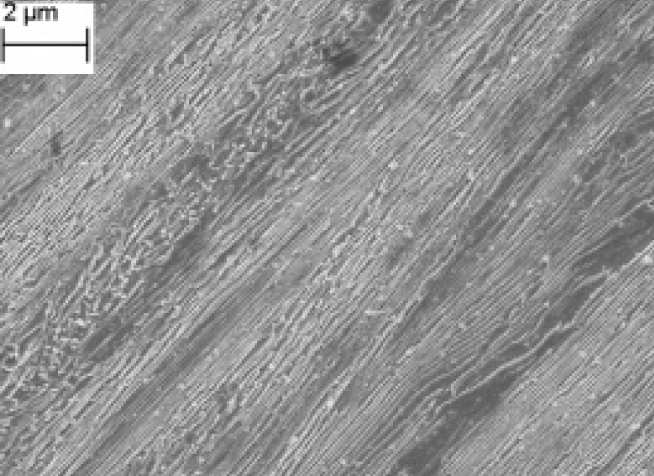

One direction of this project focuses on the design of new bcc refractory metal rich beta titanium alloys reinforced with intermetallic bcc superlattice precipitates. Alloys have been produced that comprise remarkable ultra-fine lamellar bulk nano-structures and have demonstrated exceptionally high strengths. Further development of these alloys is being made through my EPSRC Doctoral Prize Fellowship.