The research activities of the Livingston Group involve the development and application of molecular separation processes, with a strong focus on membrane technology in aqueous and non-aqueous solutions. Our researchers have in-depth knowledge of a range of separation techniques and processes including reverse osmosis, nanofiltration and ultrafiltration. The Group's particular expertise lies in organic solvent nanofitration used for separating molecules present in organic solvents. Our innovative research in this field has resulted in the creation of membranes with exceptional stability in organic solvents, coupled to high flux and excellent rejection performance.

Latest research

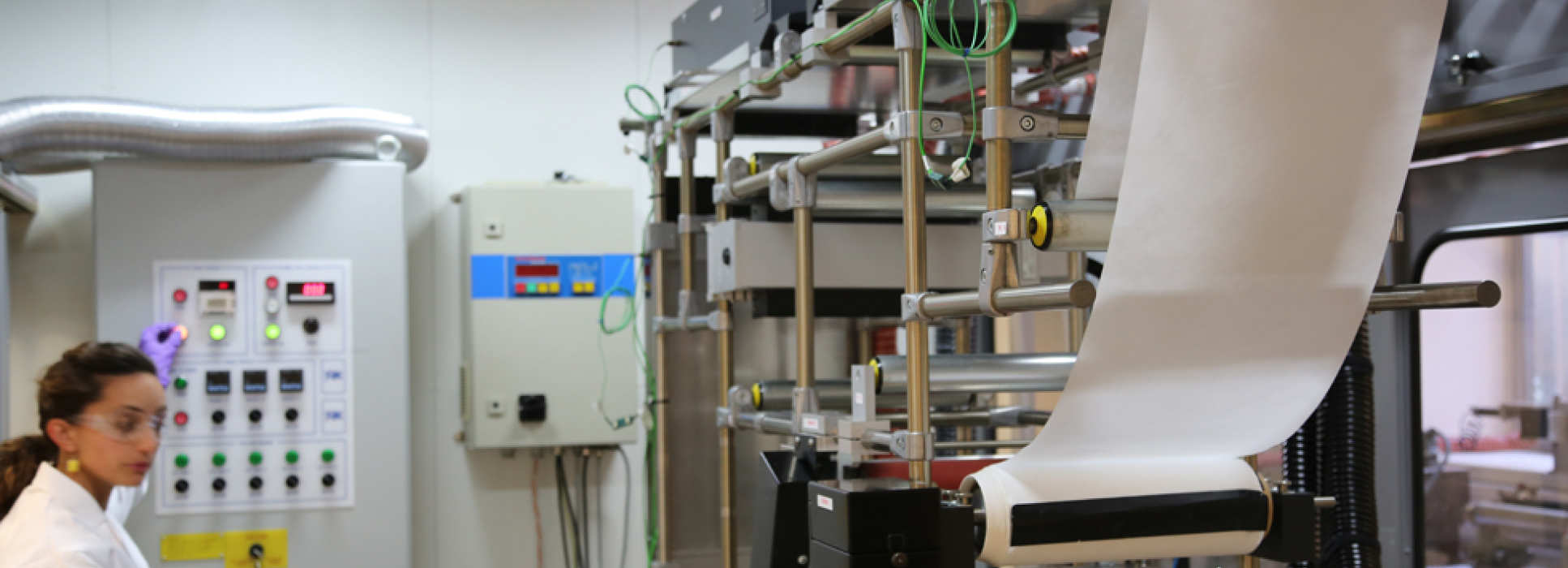

In a paper published in June 2016 in Nature Materials, Dr Maria Jimenez Solomon et al report on their research into ultrathin polyarylate nanofilms, with thickness down to 20 nm, by interfacial polymerization. Enhanced microporosity and higher interconnectivity of intermolecular network voids, as rationalized by molecular simulations, are achieved by using contorted monomers for the interfacial polymerization. Composite membranes comprising polyarylate nanofilms with enhanced microporosity fabricated in situ on crosslinked polyimide ultrafiltration membranes show outstanding separation performance in organic solvents, with up to two orders of magnitude higher solvent permeance than membranes fabricated with nanofilms made from non-contorted planar monomers.Such highly permeable and selective membranes are desirable for energy-efficient gas and liquid separations, although it has proved challenging to fabricate selective polymer membranes with controlled microporosity that are stable in solvents.

A copy of the paper can be downloaded here. Nature Materials paper May 2016, Jimenez Solomon

Research Collaborations

The Group has extensive experience of collaborating with academic and industrial partners within different process industries and in membrane manufacturing in order to pioneer novel technologies which offer cost-efficient methods to develop membrane modules and process applications. Several of our industrial partners seek to collaborate with us to develop new materials and processes to address specific separation challenges, which cannot easily be met by commercially available membranes. Combining its strengths and working closely with research partners, the Group has successfully developed innovative membrane separation techniques and membrane applications in the energy, chemicals and pharmaceuticals industries.

We have a number of exciting collaborations and are always keen to explore new interactions, participate in new academic collaborations and develop new commercial opportunities with industry. Please contact us if you wish to discuss any research opportunity.

Our research is organised into thematic areas. Please click on the tabs below to find out more about our research including our current research projects.

Group Research Themes

- Continuous Processing with Organic Solvent Nanofiltration

- Desalination

- Iterative Synthesis with Organic Solvent Nanofiltration

- Membrane Formation

The team is researching the application of organic solvent nanofiltration membranes as a continuous unit operation in typical pharmaceutical processes such as active pharmaceutical ingredients (API) synthesis, API purification and solvent exchange, API crystallisation, crude oil refining and others.

Isothermal Refining by Organic Solvent Nanofiltration

We are researching the use of membranes for refining crude oil to enable significant reductions in energy requirements for manufacturing fuels and lube products from crude oil. Current oil refinery technology is based on distillation for separation of the crude oil into fractions with varying molecular weights, followed by further reactions on some of these fractions (reforming, hydrotreating, cracking etc), which must then be further distilled. In refining, distillation typically account for more than half of all the energy consumed, since the phase change on boiling requires significant energy input. One way of avoiding this large energy consumption would be to carry out fractionation in the liquid phase via a membrane.

The majority of membrane separations to date are water based. Membranes are not generally used for molecular separations in organic systems, because until recently there were few membranes stable in organic liquids. This has changed recently - research at Imperial College has developed membranes that are stable in most organic systems. These have been commercialised through an Imperial spin out company, Membrane Extraction Technology (MET) which was acquired by Evonik Industries on 1 March 2010.

The project will work closely with partner Shell Global Solutions.

The research team is currently developing better methods for designing membranes tuned for specific applications in the energy industry. Predicting and ensuring membrane lifetime performance is critical for efficient and reliable water operations that use reverse osmosis. We are working on the fabrication of thin film composite membranes made by interfacial polymerization and the supports for these membranes.

BP-International Centre for Advanced Materials (BP-ICAM)

The Livingston Group is a founding member of BP-ICAM and leads a project which seeks to understand at the atomic level, the structure and mechanisms of membranes and to use this understanding to develop models that can better predict the behaviours of membranes in practical applications. Reverse osmosis (RO) is currently used to adjust the water salinity used in the flooding of oil reservoirs and adjusting membrane properties has the potential to enhance oil recovery.

The project aims to:

- Understand the relationship between membrane structure, properties and membrane flux.

- Develop more efficient and increased fouling resistance membranes.

- Achieve operational savings through improved membranes for enhanced oil recovery.

For more information about ICAM please visit the ICAM website.

Our research team is aiming to develop a new manufacturing process for making high value sequence-controlled polymers in a precise way. Sequence-controlled polymers include (bio)polymers such as DNA, RNA (together, "oligos") and peptides. They also include synthetic polymers for which precise control of polymer length or monomer order is necessary. These polymers are in demand by the pharmaceutical industry, where they are used as biologically active materials ("drugs"), and as parts of molecular assemblies that are used to deliver and protect drugs; and have emerging non-biological uses.

Iterative Synthesis with Organic Solvent Nanofiltration for Precision Manufacture of High Value Sequence-Controlled Polymers

Nature makes sequence-controlled polymers such as oligos or peptides by sequentially adding different monomers in a prescribed sequence. The exact order of that these monomers are added is absolutely crucial to the function of the final polymer. These same polymers are made by industrial chemistry in a way that apes Nature, through a sequence of monomer additions (we call this iterative synthesis), and a great deal of care is taken to remove the residues of unreacted monomer before the next cycle, to avoid errors in the sequence.

A very effective way of doing this is to attach the growing polymer to a solid support phase, which is washed with clean solvents to remove the residues, before the next monomer is added. When polymer growth is complete, it is cleaved from the solid support. However this process is expensive, because more monomer must be used to ensure the reaction reaches completion on the solid support, and because the supports themselves are expensive. For synthetic polymers where we want to control the molecular weight exactly, for example poly(ethylene glycols) (PEGs), which are widely used to stabilise drugs and make them last longer in the body, we could add the same monomer over and over until we reach a desired chain length, and then cleave the final polymer from the support. This is not done at present, because the cost of solid supported iterative synthesis is too high and/or the chemistry is not available.

There are other problems with solid supported synthesis. The solid supports are variable, and hard to make in a precisely repeatable way; in fact small differences in the supports can lead to quite big changes in the reactions used to link the monomers onto the growing polymer. Also, it is very hard to carry out analyses on the reaction mixture to tell whether the reactions are proceeding correctly, because the molecules of interest are inside the pores of a support material.

The multidisciplinary team of chemical engineers and chemists within the project are developing the process chemistry to improve the purification; construct Lab Plant synthesisers so that the process can be automated, select solvents and explore solvent recovery, and use quality by design to make the process more efficient. If we are successful, the project will result in a new technology for sequence-controlled polymer manufacture, and will lead to more precise polymers being available for applications in healthcare and beyond.

The team works extensively on the use of membrane separations in solvent systems where they are able to provide new routes to catalyst recycle, product separation, and solvent operations. The Group has successfully developed organic solvent nanofiltration (OSN), using membranes that are stable in solvents, and able to separate small molecules from large molecules

SynFabFun

The Livingston Group is part of an EPSRC-supported virtual membrane centre SynFabFun – from membrane material synthesis to fabrication and function – which brings together experts from the universities of Newcastle, Bath, Imperial, Edinburgh and Manchester to develop and implement new membrane systems and techniques. The five-year project, led by Newcastle University, will explore the potential of new materials to replace existing industrial membrane systems in four main industry sectors: energy, manufacturing, pharma and water. To prove their reliability, the researchers will subject the membranes to the equivalent of 30 years of use in a shorter timescale through the development and use of accelerated ageing tests, employing membranes at higher temperatures and in the presence of higher concentrations of poisons that they would otherwise experience. Their aim is to develop an immortal membrane – or at least, one that will outlive the lifetime of the industrial plant or equipment where it is being used. Another key aim is to develop a low-energy technology.

“The membrane separation of molecules from organic solvents would result in very significant energy savings," explained project lead Ian Metcalfe, Professor of Chemical Engineering at Newcastle University. "Hydrogen and/or carbon dioxide removal from a water-gas shift process in-situ – over a range of temperatures depending upon the nature of the membrane – could change the way we produce hydrogen. In terms of organic membranes we are seeking to work on systems that are already in a relaxed or equilibrium state. Such membranes cannot lose permeance as they evolve towards some equilibrium structure. For inorganic membranes we will study – for example – routes to self-healing membranes using techniques such as secondary wetting phases. We will also study hybrid membranes where for example we can introduce two permeation pathways, one for carbonate ions and one for oxygen ions, with the net outcome of a carbon dioxide permeable membrane. Such membranes would allow carbon dioxide permeation under conditions not available to organic membranes.”

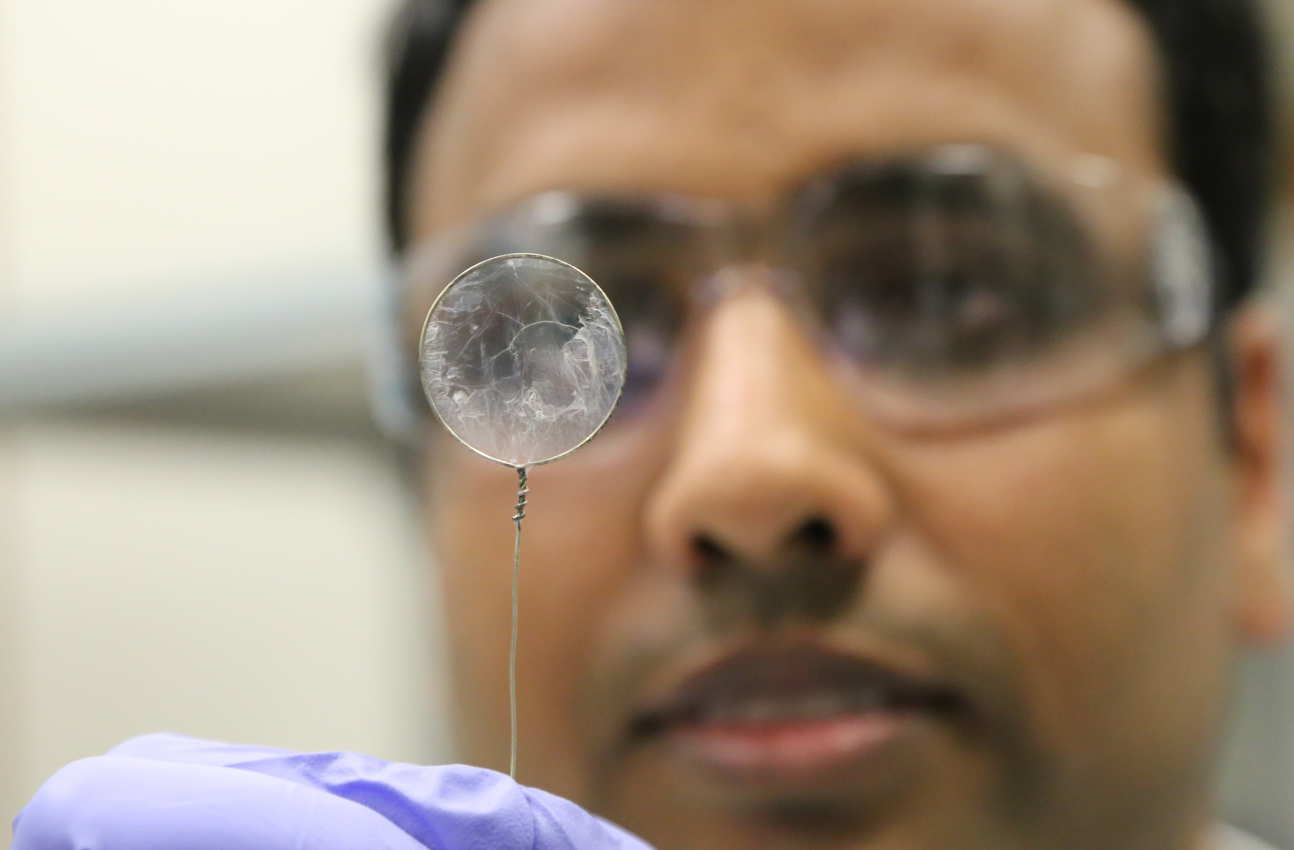

Science publication on ultrapermeable nanofilms

In a paper published in Science by Santanu Karan, Zhiwei Jiang and Andrew Livingston, we demonstrated the development of an ultrathin synthetic membrane that is both extremely permable yet very strong. The possible applications of these membranes include purifying organic mixtures in industries such as pharmaceuticals, manufacturing and oil refining. Read the paper, the associate Perspective article, the press release, and the news coverage.

Currently, over 15 per cent of world energy is used in separation systems, covering everything from processing sewage to creating microscopic nanoparticles. Although this could be improved, users are reluctant to try new technologies if their reliability is not proven, so there has been little innovation in the sector. Many widely used membranes are still made from traditional materials and systems which are often short-lived, require regular cleaning and are costly and energy intensive.

Also involved are industry partners including Johnson Matthey, Evonik, GSK, BP, Pervatech, Bluestone Global Tech, Anglian Water, Severn Trent Water, Thames Water and Scottish Water.

For more information about SynFabFun, please visit the project website here.