Current Projects

- Impact of transverse vibrations on rolling-sliding lubricated contacts

- Modelling Contact Fatigue Damage Using Crystal Plasticity

- Transient Effects in Elastohydrodynamic Lubrication

Researcher: David Uribe Saenz de Camara

Supervisor: Amir Kadiric, Daniele Dini

Sponsor: SKF

Summary

Rolling-element bearings are one of the most abundant machine components found in mechanical systems. There is a rising demand for an improved performance, higher efficiency and longer service lives. The reliability of rolling bearings has increased considerably over the last decades, and yet there are circumstances when they fail prematurely, well short of their rated life.

The aim of this project is to improve the fundamental understanding of surface damage and EHL effects that may occur when lubricated rolling-sliding contacts are subjected to transverse vibrations. This would in turn help to improve bearing performance in relevant applications such as wind turbines. Damage accumulation experiments will be performed using a triple-disc rolling contact fatigue rig, under closely controlled laboratory conditions in the elastohydrodynamic and mixed lubrication regimes.

For this purpose, a new test rig setup capable of imposing transverse vibrations has been developed. A powerful electrodynamic modal shaker is used to impose vibrations for a wide range of amplitudes and frequencies along with an in situ lubrication condition monitoring system.

Date Started: October 2019

Researcher: Xikai Yu

Supervisor: Amir Kadiric, Daniele Dini, Fionn Dunne

Sponsor: SKF

Summary

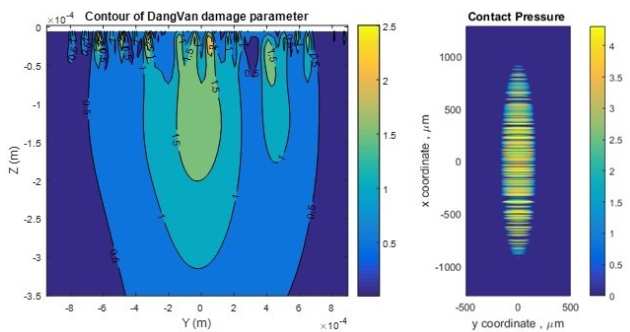

The aim of this project is to simulate surface and subsurface crack initiation in bearings and develop local fatigue damage criteria with crystal plasticity finite element (CPFE) method. The approach is able to account for the effects of material microstructure including the effects of grain morphology, anisotropic material properties and slip activities. The project is closely linked to another PhD at Imperial which is studying the RCF crack evolution with different material microstructures using experimental methods. The project aims to provide a better understanding of grain-scale mechanisms of crack initiation and therefore to contribute to better predictions of fatigue lifetimes of rolling bearings.

Date Started: December 2019

Researcher: Roland Jones

Supervisor: Amir Kadiric, Hugh Spikes

Sponsor: SKF

Summary

Our understanding of elastohydrodynamic lubrication, and thus our ability to predict EHD film thickness, in contacts operating in steady state conditions is well established, at least in full film and high lambda ratio conditions. However, this is not the case under transient conditions, where the applied load, entrainment speed or lubricant supply can change rapidly. This can occur in several important practical applications. For example, EV drive trains can be subjected to rapid changes in speed and load while the very high speeds encountered in aerospace applications can lead to variable lubricant supply in the contact inlet thus affecting the EHD film thickness and friction. One effect of these rapid changes in conditions is to disturb the oil supply to the contact and this will in turn have an effect on oil film thickness. In the extreme, a total loss of lubricant can occur due to system failures; in helicopter transmissions, the effect of this on EHD film thickness leads to major safety concerns.

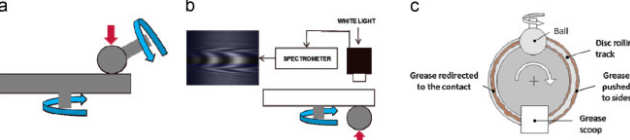

This project will use a combination of optical interferometry implemented on a new high-speed ball-on-disc rig and a relatively new electrical impedance method to study EHD film thickness and friction under highly transient entrainment speeds, loads and lubricant supply conditions. The results will inform design of mechanical components and better predictions of their performance under transient conditions.

Date Started: September 2021

Recent Projects

- Computational Fluid Dynamics (CFD) Modelling of Elastohydrodynamic Lubrication (EHL)

- Influence of Grease Composition on Friction in Elastohydrodynamic (EHD) Contacts

- Influence of Roughness Characteristics on Friction in Nominally Dry Sliding Contacts

- Influence of Steel Microstructure and Composition on RCF Crack Evolution

- Influence of Steel Microstructure and Composition on the Formation and Effectiveness of Lubricant Boundary Layers

- Lubricated cracks in Rolling Contacts

- Monitoring Hydrogen Contamination in Lubricated Contacts

- Prediction of Surface Initiated Rolling Contact Fatigue Cracks in Bearing Steel

- Premature Failures in Bearing Steels Associated with White Etching Cracks (WECs)

- Propagation of Surface Initiated Rolling Contact Fatigue Cracks in Bearing Steel

- Scuffing in Non-Conformal Contacts

- Surface Crack Behaviour under Moving Contact Load: An XFEM Study

- Tribology of Rolling Element Bearings

- Understanding and Prevention of False Brinelling Failure Mode in Rolling Element Bearings

- Wear, Plasticity and Damage Accumulation Modelling for Rolling Contact Fatigue in Bearings

Researcher: Damon Lee

Supervisor: Professor Daniele Dini, Professor Amir Kadiric

Summary

Rolling element bearings, gears and many other machine elements operate in the Elastohydrodynamic Lubrication (EHL) regime. In this regime, the lubricant creates a very thin protective film between the contacting elements, improving reliability as well as reducing friction. Therefore, understanding of EHL lubrication allows optimisation of these components in terms of reliability and efficiency, through predictions of EHL film thickness and EHL frictional losses.

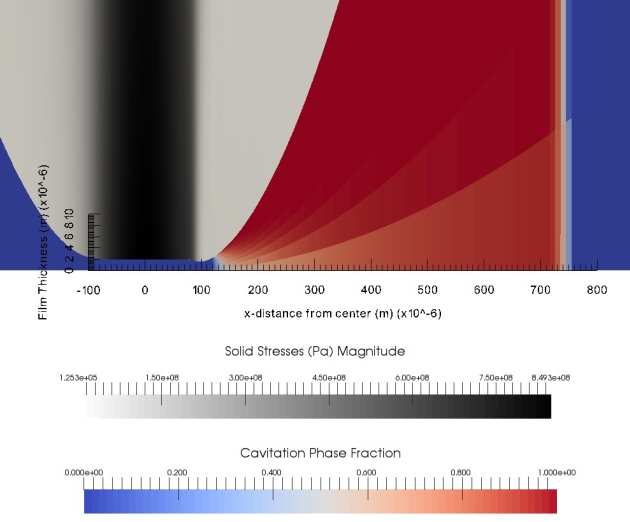

Typical methods for predicting the EHL oil film behaviour are either empirical relationships or numerical solutions to simplified fluid flow equations (Reynolds equation), coupled with an approximation to the linear elasticity equations. These methods rely on a number of assumptions that may not always hold. This project utilises finite volume Computational Fluid Dynamics (CFD) and linear elasticity to model the EHL contact through a complete solution of Navier-Stokes equations in the fluid domain, coupled with the Navier Cauchy equations in the solid domain, as well as the heat equation in all domains. A cavitation model is also implemented. This provides for more accurate treatment of relevant physical principles and allows for inclusion of additional effects such as surface roughness, surface coatings or inlet shear heating for example. EHL film thickness and friction predictions are more accurate as the full continuum mechanics description of the system is solved, resolving all gradients. The modelling domain is larger than the immediate contact so that, for instance, the entire flow, viscosity and temperature fields can be studied at the entrance to the contact. The complete shear stress field is predicted, hence providing an accurate way of studying EHL friction.

In addition to improving the EHL modelling tools, the project will attempt to generate charts that indicate the contact conditions where the simplified EHL solutions may be used with sufficient accuracy and those where the full CFD solution may be needed. Investigation will also be made into suitable rheology models for grease as a lubricant.

Researcher: Dr Nicola De Laurentis

Supervisor: Prof. Amir Kadiric

Sponsor: SKF

Summary

The aim of this project is to examine the relationship between bearing grease composition and rolling-sliding friction in lubricated contacts. The friction coefficient and lubricating film thickness of a series of commercially available bearing greases and their bled oils will be measured in laboratory tribometers. Test greases will be selected to cover a wide spectrum of thickener and base oil types, and base oil viscosities. The trends in measured friction coefficients will be analysed in relation to grease composition in an attempt to establish the relative influence of individual grease components on friction.

Researcher: Chiara Bertuccioli

Supervisor: Amir Kadiric, Finn Giuliani

Sponsor: SKF

Summary

Rolling contact fatigue (RCF) involves initiation and subsequent propagation of cracks due to cyclic stresses caused by a rolling-sliding contact, which eventually leads to the creation of a surface pit and component failure. RCF is a life-limiting failure mode of many engineering components including rolling bearings, gears and cams. Despite its obvious practical and economic importance, the fundamental mechanisms behind RCF are not fully understood.

The overarching aim of this project is to gain a fundamental understanding of the mechanisms that drives crack initiation and early propagation implementing the use of modern analytical techniques to study the material’s microstructural effects on RCF mechanisms.

Date Started: October 2018

Researcher: Kostas Pagkalis

Supervisor: Prof. Amir Kadiric

Sponsor: Afton Chemical, SKF

Summary

In the boundary lubrication regime, lubricant films are very thin so surface roughness asperities of the contacting bodies come into contact during rubbing. The load in boundary lubrication is supported mostly by contacting asperities as the local pressure exceeds what can be supported by the lubricant. Under such conditions, the protection for the contacting components can be provided by a boundary film, which is formed through the adsorption/reaction of various chemicals (additives) present in oil with the contacting solid surfaces. The formation of the boundary layers can obviously be affected by the contact conditions, but also by the composition and microstructure of the surface materials (in engineering components, this would usually be steel). Oil additives may form films preferentially with certain alloying elements and microstructures of steel. Although boundary lubrication has received significant attention in tribology research, this tends to be focused on the actual additives whereas the complete system i.e. the interaction between the steel composition and microstructure and the oil, has received little attention.

The current study will examine the influence of different steel compositions and microstructures on the formation and effectiveness of boundary films under concentrated contact and with a selection of different additives/lubricants. Different kinds of steel microstructures and compositions should be used to understand their influence with different additives and how they affect the boundary film formation. The aim of the project is to find which alloying elements with the existing lubricants are mostly beneficial to the boundary film formation.

- Leaders: Daniele Dini, Andy Olver

- Staffing : PhD Student + Post Doctoral Researcher

- Staff: Robbie Balcombe, Mark Fowell

Task:

To investigate role and importance that entrapment and pressurisation of lubricant within surface breaking cracks may play in the propagation of such cracks under rolling and sliding conditions. The work includes investigation of the influences of lubricant physical properties on crack development. The experimental work includes lubricant and crack face displacement tracking . Numerical investigations are based on a custom boundary element code developed within the project for cracked bodies.

To investigate role and importance that entrapment and pressurisation of lubricant within surface breaking cracks may play in the propagation of such cracks under rolling and sliding conditions. The work includes investigation of the influences of lubricant physical properties on crack development. The experimental work includes lubricant and crack face displacement tracking . Numerical investigations are based on a custom boundary element code developed within the project for cracked bodies.

Date:

2007 - 2011

Researcher: Dr Arnaud Ruellan du Crehu

Supervisor: Prof. Amir Kadiric

Sponsor: SKF, Marie Curie

Summary

Presence of hydrogen in bearing steels is known to promote the onset of unpredictable rolling contact fatigue related failures. In order to better predict the risk of these failures and design countermeasures, there is a need to better identify hydrogen sources in lubricated contacts.

Bearing steel itself inevitably contains a certain amount of hydrogen, but evidence suggests hydrogen can also be generated through the tribological decomposition of lubricant compounds, subsequently promoting atomic hydrogen permeation. Hydrogen contamination remains very difficult to monitor due to very low concentrations, its versatility and diffusivity.

This project aims to apply different hydrogen monitoring techniques on tribometers simulating rolling/sliding lubricated contacts of bearing steels. Focus of the study is on comparative measurements to assess the influence of various parameters such as steel and lubricant composition, water contamination, temperature and frictional energy on the evolution of hydrogen and to try to correlate hydrogen gas evolution and hydrogen absorption into the bearing steel.

Researcher: Bjoern Kunzelmann

Sponsor: SKF

Supervisor: Amir Kadiric, Daniele Dini

Summary

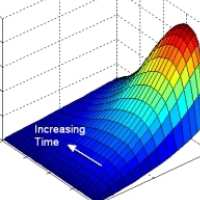

Surface initiated rolling contact fatigue, leading to a surface failure known as pitting, is a life limiting failure mode in many modern machine elements, particularly rolling element bearings. This project builds on previous work at Imperial College which for the first time identified two phases of RCF crack propagation which leads to pitting failure in the ultimate stage. Phase I crack propagation is associated with shorter cracks (<100µm) and exhibits relatively slow crack propagation rates with frequent crack arrests whereas phase II is associated with longer cracks (>100µm) which show rapidly increasing crack growth rates following a Paris like power law [1].

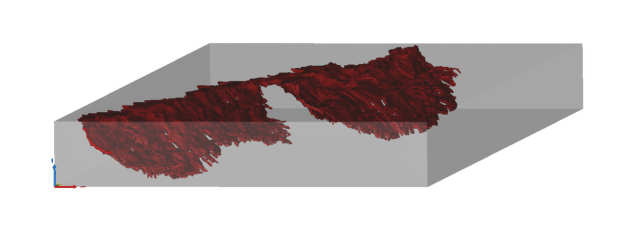

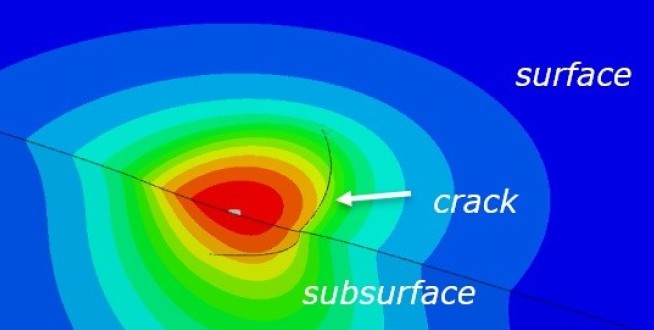

A triple-disc contact machine is used to determine the major parameters which influence rolling contact fatigue crack growth including surface topography, fluid crack interaction, contact size etc. In parallel, a three-dimensional numerical crack model (Figure 1) has been developed which is able to predict stress intensity factors for crack morphologies which were observed in the experiments. Furthermore, the numerical model accounts for effects such as crack face friction and fluid pressurisation in the crack which can have significant effect on stress intensity factors experienced at the crack tip. This study focuses on the prediction of rolling contact fatigue crack growth with linear elastic fracture mechanics (LEFM). As most of the rolling contact fatigue lifetime is consumed by crack propagation the prediction of the crack growth with LEFM allows the estimate of the residual bearing life after crack detection. A combined numerical and experimental approach is used in order to determine the major influencing parameter for different operating conditions and hence contribute to development of better contact fatigue lifetime predictions.

[1] P. Rycerz, A. Olver, and A. Kadiric, “Propagation of surface initiated rolling contact fatigue cracks in bearing steel,” Int. J. Fatigue, vol. 97, pp. 29–38, 2017

Date Started: July 2018

Researcher: Francesco Manieri

Supervisor: Prof. Amir Kadiric

Sponsor: SKF

Summary

Premature failure of components is a significant problem in the energy and transport industries, particularly since energy requirements have become more ambitious and demanding. It is well known that components in gearboxes, especially at bearing location, tend to fail below the expected life. Generally, one tends to identify the problem of premature failure with a particular failure mode, i.e. white etching cracks (WECs) as they are very likely to appear in premature failures. A WEC is a crack accompanied by a microstructural change that appears white after etching. The aim of this project is to reproduce premature failures under controlled laboratory conditions, using a triple-contact rig, clarifying the relationship with WECs and identify their root causes.

Researcher: Dr Pawel Rycerz

Supervisor: Dr Amir Kadiric, Professor Andrew Olver

Sponsor: SKF

Summary

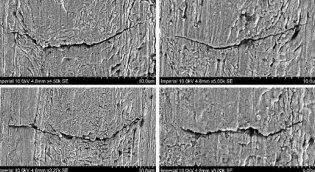

Surface initiated rolling contact fatigue, leading to a surface failure known as pitting, is a life limiting failure mode in many modern machine elements, particularly rolling element bearings. Most research on rolling contact fatigue considers total life to pitting. Instead, this work studies the growth of rolling contact fatigue cracks before they develop into surface pits in an attempt to better understand crack propagation mechanisms.

A triple-contact disc machine will be used to perform pitting experiments on bearing steel samples under closely controlled contact conditions in mixed lubrication regime. Crack growth across the specimen surface will be monitored and crack propagation rates extracted. The morphology of the generated cracks will be observed by preparing sections of cracked specimens at the end of the test.

Date

2010-2014

Researcher: Bo Peng

Supervisor: Dr Amir Kadiric

Sponsor: SKF

Summary

Scuffing is a surface failure mode that occurs in sliding-rolling contacts subjected to high loads and high sliding speeds, such as those in gears and cam-followers. Owing to its sudden onset, rapid progression and dependence on both fluid and boundary lubricant films, scuffing is difficult to study in a repeatable manner. In this project, we will develop a scuffing test method based on contra-rotation. We will extend the method to higher loads using a new experimental set-up and apply it to study the onset of scuffing with a selection of model and fully-formulated lubricants.

Date

2015-2019

Researcher: Dr Yilun Xu

Supervisor: Dr Amir Kadiric

Sponsor: SKF, Marie Curie

Summary

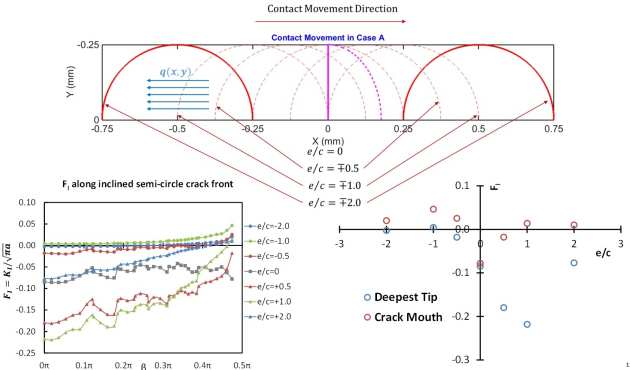

Three-dimensional extended finite element method (XFEM) calculations that simulate penny shape surface-break crack behaviour under a rolling contact are conducted. The interaction between the surface-break crack and the moving contact is investigated under various working scenarios, including coefficient of friction, relative position of the crack cut and the contact size, etc. Stress intensity factors (SIFs) are evaluated along the crack front based on the stress field, which are further applied to estimate the propagation rate of the crack under a certain scenario. Numerical results illustrate the most vulnerable position of contact with respect to the crack that leads to a fast crack propagation. Besides, this research sheds light on the dependence of SIFs values along a crack front upon the parameters that define a rolling contact scenario. Relative slips between crack surfaces are also investigated under various rolling contact scenarios in this project.

Date

2016-2018

Researcher: Dr He Liang (Holly)

Supervisor: Prof. Amir Kadiric

Sponsor: SKF, European Commision

Summary

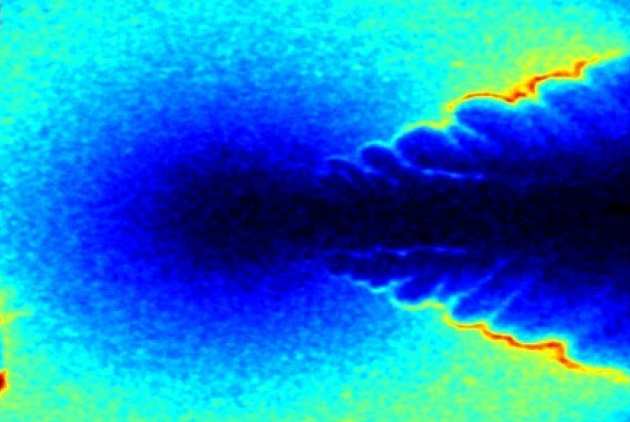

This project uses a custom-made, model ball bearing rig to directly observe and measure lubricant films in the rolling track as well as EHL films in the ball-ring contacts at contact pressures and rotational speeds commensurate with those present in a real rolling bearing. Glass ring is used as the outer bearing race allowing full optical access to the EHL contact. Lubricant films in the rolling track and contact inlet are measured using fluorescence technique, while optical interferometry is utilized to measure thin EHL films in ball-ring contacts. The results are presented to illustrate the influence of multiple factors including entrainment speed and oil fill level on oil films in and around the contact.

Researcher: Rachel Januszewski

Supervisor: Dr Amir Kadiric

Sponsor: SKF

Summary

False brinelling is a type of surface damage that most commonly occurs in non-conformal, nominally stationary contacts that are subjected to externally generated vibration. All machine elements that rely on non-conformal, rolling-sliding contacts in their operation can suffer from false brinelling, but it is most commonly observed in rolling element bearings, especially in stand-by equipment stored near running machines and in the transport of automotive vehicles by rail or sea.

False brinelling is a specific type of a more general contact damage mechanism of fretting, often referred to as fretting corrosion. The underlying mechanisms causing fretting and false brinelling are thought to be similar, but false brinelling in rolling bearings has an added complication that the oscillatory motion is not pure sliding but also involves rolling of rolling elements on bearing raceways.

The aim of the proposed research is firstly, to gain a better understanding of the factors that drive the onset and progression of false-brinelling damage and secondly, to provide potential preventative measures, be it through the improvements in bearing design or lubricant formulation.

Date

2016-2020

Researcher: Dr Achilleas Vortselas

Supervisor: Prof. Amir Kadiric

Sponsor: SKF

Summary

The aim of this work is to develop new physical models for selected tribological operating conditions and failure including: wear model, crack initiation and propagation model, contact stress and temperature predictions, plasticity and damage accumulation. The fundamental models developed here have a wide applicability to many machine elements including, bearings, gears, cam-followers and constant velocity joints.

Specifically, it involves the development new semi-analytical model for elastic-plastic contact along the lines of Chiu’s theory for stresses and displacements in a half space due to a cuboidal volume with uniform residual strains. This will enable the team to study damage accumulation and crack propagation in rolling-sliding contacts, using various stress, strain and energy based criteria. In conjunction with experimental observations and numerical simulations on crack growth, surrogate models of the bearing material’s degradation behaviour can be developed, to be used in stochastic simulations of bearing life.

Short Term Projects

- Film thickness and friction measurements with different surface topography

- Rheology of selected oils

- Fluorescence observation of lubricant behaviour on molecular level

- Contact mechanics of rough surfaces

- Thermo-mechanical modelling

- Lubrication of bearing surfaces

- Contact mechanics modelling of dry layered surfaces