Wenman widget

- The durability of Magnesium-Silicate-Hydrate based materials made from Brucite

- Modelling the behaviour of interfaces in triso coated particle fuel during thermal transients using peridynamics

- Atom probe tomography and microscale mechanical testing of neutron irradiated PWR reactor pressure vessel steel

- Peridynamics and finite element crystal plasticity modelling oxidation of Zr alloys

- Mesoscale finite element phase field modelling of liquid lithium corrosion of steels

- Finite element modelling of the corrosion of stainless steels/CuCrZr for STEP reactor cooling systems

Mercedes Baxter Chinery (Research Postgraduate)

Mercedes Baxter Chinery (Research Postgraduate)

Co-supervised by Prof Hong Wong and Prof Chris Cheeseman

Member of Nuclear Energy Futures CDT

The legacy waste stream at Sellafield is mainly composed of a brucite-rich sludge. The aim of this PhD is to determine if a reduction of the waste in the ponds and silos can be achieved upon encapsulation by using the waste as a component in the encapsulating cement as well as being the encapsulated waste.

Understanding the durability of M-S-H, especially in the context of waste encapsulation, and the hydration mechanisms when using magnesium hydroxide as a source will be the basis of the research conducted. Early properties, the evolution of M-S-H and resistance to possible environments will all be tested.

Angelo Battistini (Research Postgraduate)

Angelo Battistini (Research Postgraduate)

In collaboration with National Nuclear Laboratory

Member of Nuclear Energy Futures CDT

TRistructural ISOtropic coated particle fuels (TRISO CPF) have been developed as a possible fuel solution for high temperature nuclear reactors, which offer the possibility of nuclear cogeneration-powered industrial facilities and hydrogen production. This project aspires at demonstrating the possibility to simulate the behaviour of this new type of fuel in a reactor and especially the behaviour of the interfaces between its layers with bond-based Peridynamics. Peridynamics is a non-local modelling technique which is an integral formulation of the finite element solution of continuum mechanics. The advantages of an integral approach are clear when crack formation and propagation are investigated, as it overcomes the limits of the partial differential equations representing most finite element models available to simulate the behaviour of materials.

The project focused on determining residual stresses arising during the fabrication of TRISO particles, validating the Peridynamics model against an experimental campaign of three-point-bend tests, and finally it will address TRISO layers behaviour during typical thermal transient in a reactor.

Ryan Stroud (Research Postgraduate)

Ryan Stroud (Research Postgraduate)

Co-supervised by Dr Stella Pedrazzini

In collaboration with EdF Energy

Member of Nuclear Energy Futures CDT

My project uses the hot cells and active focus ion beam facilities at the Materials Research Facility (MRF) in Culham and the active materials atom probe facility at Oxford University to study irradiated material from a PWR. The aim is to study how the neutron irradiation damage has evolved at the nano-scale and compare how microstructural changes, made by pre-straining the material, before irradiation, has changed the radiation response of the steel. My end goal is to use the results to extend the lifetime of current LWRs, which in turn will help mitigate the release of CO2 emissions.

Susannah Lea (Research Postgraduate)

Susannah Lea (Research Postgraduate)

Co-supervised by Prof Fionn Dunne

In collaboration with Rolls-Royce plc

Member of Nuclear Energy Futures CDT

The aim of the project is to understand the growth behaviour of zirconium oxide and how the oxide layer affects hydrogen pickup. Currently hydrogen pickup is the life limiting factor for nuclear fuel, due to embrittlement by hydride formation and determining the oxide growth is key to understanding this, since there have been links made between parabolic and sub-parabolic growth of the oxide and hydrogen uptake. There is a transition associated with the formation of cracks at an oxide thickness of 1-2 microns and just before this transition is when the hydrogen uptake increases. Stress relief is a possible cause of crack nucleation, as the stress within the oxide increases with growth.

This project will develop an oxygen diffusion model where metal turns into oxide and includes the oxide expansion, leading to the stress states in both the oxide and underlying metal. The crack nucleation and growth in the oxide will also be explicitly modelled and linked to the metal microstructure. This will be validated by characterisation work of cracks at the microscale carried out by Jacobs and Rolls-Royce. The project will link a crystal plasticity model for Zircaloy-4 with models of brittle fracture of ceramics utilising a technique called peridynamics. This will be done in Abaqus by pinning a peridynamics mesh to a finite element mesh with tie constraints, so that stress in the oxide will drive deformation in the underlying metal and also back again into the oxide, leading to damage and cracks.

Alex Lhoest (Research Postgraduate)

Alex Lhoest (Research Postgraduate)

Co-supervised by Dr Emilio Martinez-Paneda

In collaboration with UKAEA

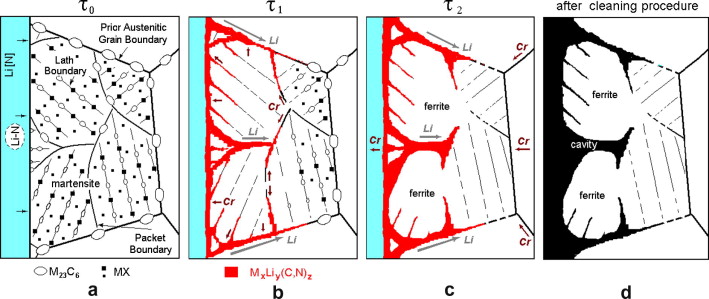

Liquid lithium is a proposed coolant for the STEP fusion reactor because of its ability to remove heat efficiently, as a liquid metal, but with the added advantage that Li can breed tritium from neutron interactions. One of the proposed materials that the liquid lithium will be in contact with is grade P91 steels. These steels have been used extensively in the fossil fuels and nuclear industry and they have both reasonable corrosion/oxidation resistance due to the Cr present but more importantly have high creep strength at elevated temperatures required by STEP. P91 grades are ferritic-martensitic steels with a highly complex microstructure that contains a variety of both precipitates and inclusions. These are well known to influence the creep properties but are likely to have a role to play in the corrosion of the steel by liquid lithium. At Imperial we have recently been developing a model, within the finite element phase field method framework, that can provide the corrosion rate and generate polarisation curves similar to those observed experimentally during the measurements of corroding metals. These models will be developed to study single grain, bi-crystals and grains with a single second phase particle embedded, of the various types found in P91 steels, to assess which particles are critical in the presence of Li and control the corrosion behaviour of these steels. These models will be developed in parallel with the localised corrosion experiments that will take place at UKAEA of P91 steels in liquid lithium. The models once developed for simple cases will also attempt (subject to experimental data availability) to include the effect of radiation damage through hardening and potentially grain boundary chemical segregation effects in these steels on the corrosion behaviour in liquid Li.

Jason Lee (Research Postgraduate)

Jason Lee (Research Postgraduate)

Co-supervised by Dr Emilio Martinez-Paneda

In collaboration with Singapore Nuclear Research and Safety Initiative and UKAEA

Member of Nuclear Energy Futures CDT

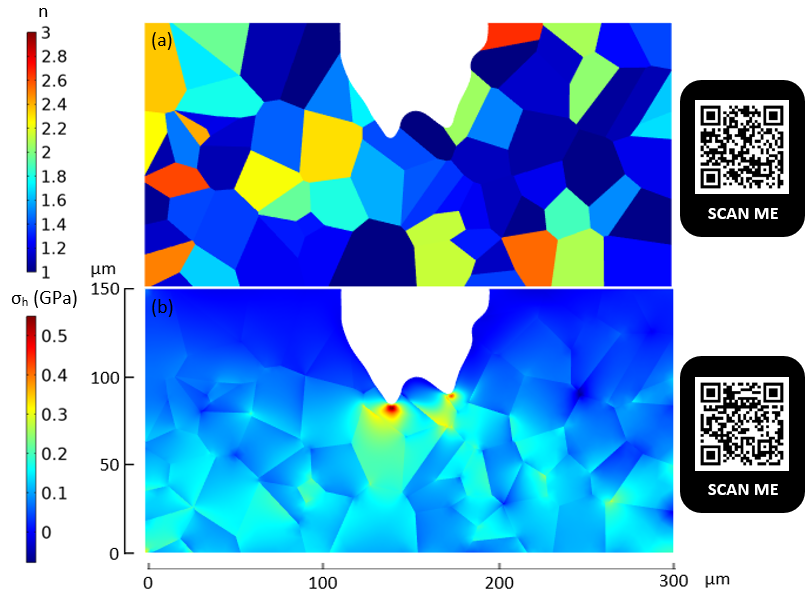

The STEP programme roadmap is very tight, with a need to down select materials in the next few years, before build can begin in 2032, if the programme is to deliver by 2040. There is a need to select the materials that will carry coolant to remove reactor heat, which might be stainless steels, as used in many fission plants, and also proposed for ITER, using boronated coolant water. To achieve the ambitious goals for fusion state-of-the art corrosion modelling capabilities will be needed to support experiments. This project will use phase field approaches embedded in finite element models, being developed at Imperial College, jointly by the Martinez-Paneda and Wenman groups to model corrosion development (including microstructure, electrolyte ion concentrations, pit nucleation and growth and transition to stress corrosion cracks). The work will use either or both the COMSOL and ABAQUS finite element codes. The current models build on the work of Turnbull et al. (2008). that showed that pit growth in stainless steels can be explained by the development of plastic strains at the pit sides that lead to oxide fracture and increase the corrosion rate of the underlying metal. These models have very recently been enhanced further to by addition of electrolyte ion concentrations and thus can be used to model a range of coolant chemistries and then can be further advanced by addition of microstructure via crystal plasticity approaches allowing the effects of localised stress/strains, due to crystal orientation, to be considered in the corrosion process. The models, whilst initially tested on stainless steels can be developed further/adapted to other coolant/materials combinations such as CuCrZr or martensitic/ferritic steels as proposed for STEP.