We have a variety of in situ testing platforms that allow high-resolution, real-time observation of material behaviour under mechanical and thermal stimuli inside scanning electron microscopes.

Our main facilities include:

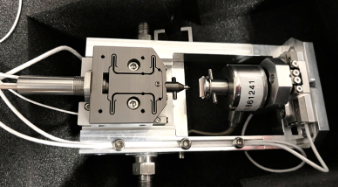

- An Alemnis micromechanical testing stage (Alemnis Standard Assembly)

- Two Deben Microtest tensile/compression/bending stages

- A Gatan Murano heating stage

- A Gatan C1003 cryo stage*

Accordion Widget

- Alemnis standard assembly

- Deben Microtest 300 N mechanical testing stage & 2 kN mechanical testing stage with heating and in situ EBSD

- Gatan Murano heating stage

- Gatan C1003 cryo stage

- References

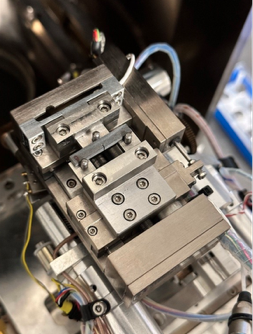

The Alemnis standard assembly is highly effective for measuring the micromechanical properties of materials and analysing the local mechanical behaviour of individual microstructural units.

The Alemnis standard assembly is highly effective for measuring the micromechanical properties of materials and analysing the local mechanical behaviour of individual microstructural units.

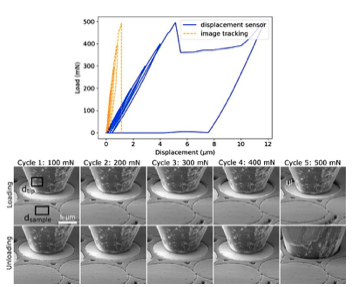

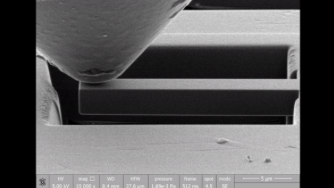

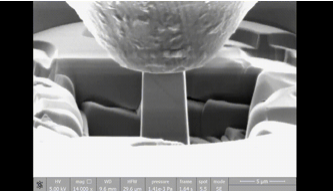

With a wide range of indenter tip geometries and careful experimental design, we can perform various types of micromechanical tests, such as fibre bending, push-out testing, and powder compression.

These tests are often combined with focussed ion beam (FIB) milling of small-scale specimens and electron backscatter diffraction (EBSD), enabling the testing of small-scale samples with known crystal orientations and well-defined geometries. This approach allows for the exploration of the fundamental properties of materials during deformation and fracture.

Fibre push-out tests of a ceramic matrix composite [1].

Microcantilever bending test of Zr3AlC2 MAX phase.

Micropillar compression test of hydrides in zirconium [2].

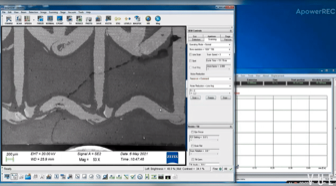

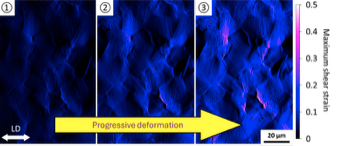

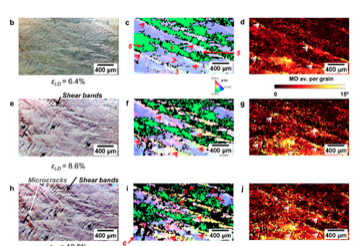

These two stages are ideal for testing the mechanical properties and observing the failure processes of larger-scale specimens under tension, compression, and bending configurations, providing a more direct representation of material degradation and failure mechanisms seen in real-world engineering applications.

These two stages are ideal for testing the mechanical properties and observing the failure processes of larger-scale specimens under tension, compression, and bending configurations, providing a more direct representation of material degradation and failure mechanisms seen in real-world engineering applications.

The 2 kN stage also supports in situ EBSD analysis and heating up to 1000 °C.

3-point bending test of an alumina-steel composite. Courtesy of Dr Shitong Zhou.

2D strain maps on the surface of a zirconium sample during tensile test.

Microstructural evolution during in situ creep test of Sn-3Ag-0.5Cu solder [3].

The Murano heating stage is designed for in situ heating experiments (up to 950°C), making it suitable for studying thermal processes such as phase transformation and thermal stress-induced degradation.

The Murano heating stage is designed for in situ heating experiments (up to 950°C), making it suitable for studying thermal processes such as phase transformation and thermal stress-induced degradation.

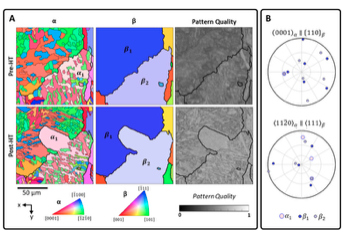

The facility also supports in situ EBSD characterisation with a pre-tilted stage holder and a Bruker high-temperature phosphor.

In situ EBSD characterisation of blocky α grain growth in zirconium [4].

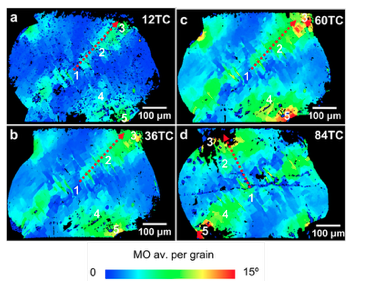

In situ EBSD characterisation of the microstructural evolution of Cu/Sn-3Ag-0.5Cu/Cu solder joint during thermal cycling [5].

The C1003 cryo stage operates in the temperature range between -185 °C and 400 °C, and is ideal for studying temperature-sensitive materials, preserving hydrated samples like biological tissues, preventing beam damage to soft polymers or volatile compounds, and enabling the observation of dynamic temperature-dependent phenomena such as phase transitions and structural changes in materials.

The C1003 cryo stage operates in the temperature range between -185 °C and 400 °C, and is ideal for studying temperature-sensitive materials, preserving hydrated samples like biological tissues, preventing beam damage to soft polymers or volatile compounds, and enabling the observation of dynamic temperature-dependent phenomena such as phase transitions and structural changes in materials.

The stage is currently being used to understand the low-temperature behaviour of various materials, including polymer composites, for liquid hydrogen storage.

References

[1] O. Gavalda-Diaz et al., Acta Mater., 215 (2021) https://doi.org/10.1016/j.actamat.2021.117125

[2] S. Wang et al., Acta Mater., 200 (2020) https://doi.org/10.1016/j.actamat.2020.09.038

[3] T. Gu et al., Acta Mater., 196 (2020) https://doi.org/10.1016/j.actamat.2020.06.013

[4] R. M. Birch & T. B. Britton, Acta Mater., 278 (2024) https://doi.org/10.1016/j.actamat.2024.120151

[5] T. Gu et al., Scripta Mater., 175 (2020) https://doi.org/10.1016/j.scriptamat.2019.09.003

* We gratefully acknowledge the contributions of Professor Ben Britton, whose support helped establish some of these facilities.

People List Widget

-

Professor Finn Giuliani

/prod01/channel_3/media/images/people-list/FG.jpg)

Location

Department of Materials

LM04D, Royal School of MinesSupport with

Academic Lead of the facility

-

Dr Siyang Wang

/prod01/channel_3/media/images/people-list/Photo_Siyang.jpg)

Location

Department of Materials

LG04, Royal School of Mines

Support with

Alemnis micromechanical test stage

Deben Microtest 300/2k N stages

Gatan Murano heating stage

Gatan C1003 cryo stage

In situ EBSD characterisation with Microtest & Murano stages -

Dr Oriol Gavalda Diaz

/prod01/channel_3/media/images/people-list/thumbnail_photo_Oriol.jpg)

Location

Department of Materials

1.04, Royal School of MinesSupport with

Alemnis micromechanical test stage

Deben Microtest 300/2k N stages

Gatan Murano heating stage