Rediscovered ceramic has potential in hypersonic flight

by Colin Smith

A structural ceramic that can withstand temperatures three times hotter than lava shows promise in hypersonic air travel, say researchers.

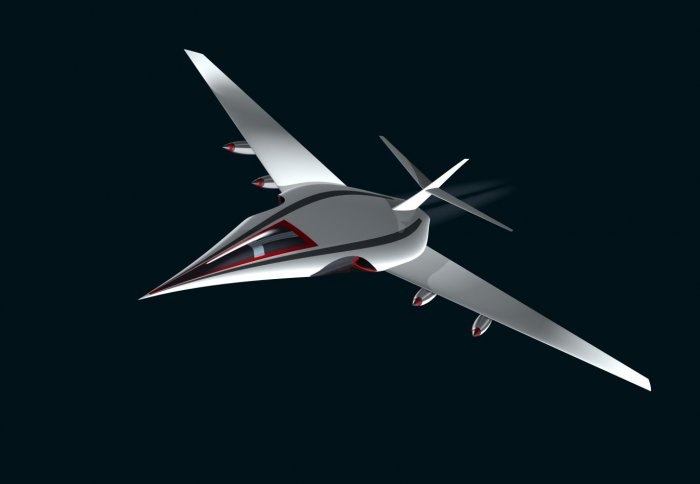

Researchers in the UK and around the world are currently working on prototype technologies that could enable new types of aircraft to travel at hypersonic speeds - five times faster than the speed of sound. At these speeds, planes would have enough power to leave the Earth’s atmosphere and fly through space, before re-entering to arrive at their destination, which could dramatically cut travel times.

One of the current challenges of making hypersonic travel a reality is developing a material that can shield these planes from the extreme temperatures of over 2000°C caused by their re-entry into the atmosphere. Ultra High Temperature Ceramics (UHTCs) are a group of materials that can withstand the extreme temperatures above 3000°C, making them suitable for use in hypersonic travel. Their strong chemical bonds make them exceptionally durable and useful in erosive, corrosive and high temperature environments.

Paving the way in ceramics

Researchers at the Centre for Advanced Structural Ceramics at Imperial College London are carrying out world leading research into structural ceramics in a range of areas, including materials that could be used in the aerospace industry.

Over the last year, PhD student Mr Omar Cedillos has shown that UHTC hafnium carbide can withstand temperatures of more than 4050°C rather than the previously reported 3950°C.

Our results are promising and suggest that hafnium carbide may be a material that could shield these planes from heat generated by friction between air and the plane’s surface.

– Mr Omar Cedillos

PhD student, Department of Materials

Cedillos says this finding represents a significant milestone and could pave the way for using the ceramic to shield areas such as the wings and nose cone - parts of the plane that would need most protecting from extreme heat.

Cedillos, who is from the Department of Materials at Imperial, said: “Although hypersonic planes are still a long way from being ready to board, they could revolutionise the way we travel. A trip from Los Angeles to New York could take 15 minutes”

“However, friction between the craft and the atmosphere on re-entry generates enormous amounts of heat, which could destroy the craft if it is not protected properly. Our results are promising and suggest that hafnium carbide may be a material that could shield these planes from heat generated by friction between air and the plane’s surface.”

Everything old is new again

Scientists first began experimenting with hafnium carbide in the 1960s and showed that it could withstand temperatures of around 3950°C. Despite its favourable properties such as extreme hardness and high melting point, its technical complexity and high manufacturing costs limited its use.

Since then, advances in hypersonic research and better laboratory and computing equipment has enabled researchers to improve how they analyse UHTCs. The fact that UHTCs are currently the only materials in the world that can withstand the extreme temperatures in hypersonic travel has also renewed scientific interest.

Analysis in seconds

In April 2014, Cedillos carried out experiments at the Institute for Transuranium Elements (ITU) in Karlsruhe, Germany. He used a high powered laser technique pioneered at ITU, which they normally use to understand how ceramics perform in the harsh environment of a nuclear reactor.

The technique uses lasers to create the intense, focussed heat required to melt the UHTC. Another laser is used to analyse how the material melts as it is being heated. A device called a pyrometer measures the material’s melting point. This technique is highly accurate and enabled Cedillos to analyse the material in seconds.

Testing times

Cedillos also tested the UHTC in a number of different laboratory experiments to determine its suitability for aerospace manufacturers. For example, many components in aircrafts are often made from a mixture of materials called composites because they have the advantage of making them more durable or stronger. To test its suitability as a composite material, Cedillos mixed hafnium carbide with another UHTC called tantalum carbide and subjected it to the ITUs high powered laser technique to determine how it withstood different harsh conditions.

A coat for protection

The next step will see Cedillos and his colleagues at the Centre focussing on ways of preventing hafnium carbide and other UHTCs from reacting with oxygen in the atmosphere at high temperatures, which causes degradation. They are exploring the potential of different coatings and additives to prevent this breakdown.

The research was carried out in conjunction with Queen Mary University London and Institute for Transuranium Elements, Germany. Mr Cedillos’ research is supervised by Professor Bill Lee, Director of the Centre for Nuclear Engineering, and funded by the Mexican Government Science Council.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Colin Smith

Communications and Public Affairs