From waste to value: the coming of age of the lignin bio-economy

New review paper looks at the value of emerging technologies of lignin biorefining processes for production of renewable fuels, chemicals & materials

The planet’s rapidly depleting fossil fuel reserves, combined with an ever-rapidly growing global population, has driven a need to find renewable resources to meet increasing energy and material demands. Plant dry matter, known as lignocellulosic biomass, provides an ample renewable resource that can be processed into a broad spectrum of textiles, fuels and commodity chemicals. This conversion of biomass into value-added products has become a major research area in the pursuit of alternative fuels, chemicals and materials.

Lignocellulosic biomass is composed of cellulose, hemicellulose and lignin. Of the three, lignin is currently the most poorly utilised. In fact, it is released from the cellulosic fibres as an industrial waste of the paper and pulp industries. Nowadays, the lignin waste is incinerated to recover the pulping chemicals and generate electricity. In a landmark review entitled "Paving the Way for Lignin Valorisation: Recent Advances in Bioengineering, Biorefining and Catalysis" a world-class team of experts from Europe and USA explored how highly-efficient, cost-effective, lignin biorefinery could be delivered through emerging technologies. Dr Roberto Rinaldi, a Senior Lecturer in the Department of Chemical Engineering was the lead author on the paper.

The review was published in Angewandte Chemie, one of the world’s leading Chemistry journals, and provides a "beginning-to-end" approach for the route to economic viability in lignin biomass production. It covers a wide range of topics and strategies towards economically viable biomass production and provides some unique perspectives on strategies for lignin bioengineering, biorefining and catalysis. In the paper, the authors discuss the concept of an integrated “biorefinery” where every stage of the process stream is considered from fundamental and industrial angles using expertise and knowledge from a broad array of scientific disciplines. Furthermore, the authors stress that these “biorefineries” should be designed to optimise the whole production system and need to consider potential market and price volatility of targeted products in conjunction with other process streams.

Dr Roberto Rinaldi, lead author on the paper said, “For the first time we have looked at the lignin biorefining process as a whole system from beginning to end. Using this unique approach it has become clear that the optimal, economically viable approach to lignin biorefining requires a fine-tuning of the upstream and downstream processing stages, which are dependent on bioengineering and catalysis technologies as much as they are on market considerations. The best approach for different products will depend on the circumstances and future biorefineries must be designed with the whole system in mind from the outset.”

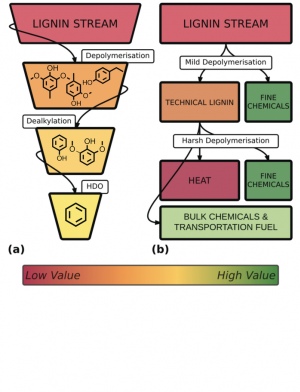

Two alternative approaches to depolymerisation of low-value lignin streams (Scheme 9 in the paper)

There remains considerable scope for the development of lignocellulosic biomass value chains for the production of energy, chemicals, polymers and materials. The recent advances described in the paper, on the bioengineering and biorefining of lignocellulosic biomass taken together with the economic factors affecting processing could lead to a better utilisation of this renewable resource. This has the potential to alleviate the current reliance on petrochemical sources with significant world-wide implications on environmental sustainability.

Dr Roberto Rinaldi studied Chemistry at the State University of Campinas, Sao Paulo, Brazil and received his PhD in 2006. A year later, he joined the Max-Planck-Institut für Kohlenforschung as postdoctoral research fellow where he became a Junior Group Leader in 2009. In 2010 he received the prestigious Sofja-Kovalevskaja Award from the Alexander von Humboldt Foundation, allowing him to launch his independent research group and develop outstanding research on lignin valorisation. He was appointed Senior Lecturer at the Department of Chemical Engineering at Imperial College London in 2015.

Reference:

Article co-written with Dora Olah an Undergraduate student in the Department of Chemical Engineering.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Michael Panagopulos

Department of Chemical Engineering