Researchers develop porous carbon foam material with wide range of applications

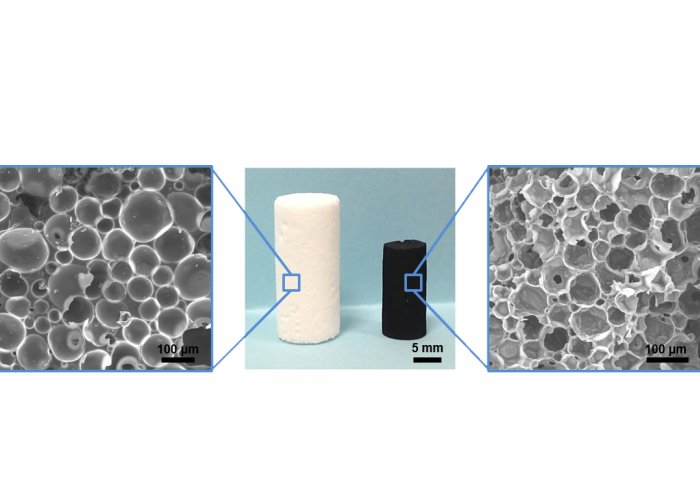

PolyHIPE derived from particle stabilized emulsion before & after carbonization showing the retention of the cylindrical shape after heating

Imperial researchers have developed a highly-efficient and cost-effective method for producing a carbon foam material with wide ranging applications.

Researchers from Imperial College London have developed a new, low-cost method for producing a carbon foam material that can be used for a variety of applications. The research was published in the leading journal Carbon, and was co-authored by members of the Departments of Chemical Engineering and Chemistry from Imperial College London and also involved collaborators from the University of Liverpool and the University of Vienna.

The method they developed involves the carbonization of polymers derived from particle stabilized high internal phase emulsions (polyHIPEs). A mouldable emulsion-template allows for the synthesis of carbon foams, or ‘carboHIPEs’ in many different shapes and sizes, with the materials displaying hierarchical porosity ranging from micropores to emulsion-templated macropores, resulting in very high surface areas.

These carbon foams have a wide range of possible applications, from catalyst support through gas separation to energy storage devices. Some of the benefits of these foams over other materials include low cost of production, low density and electrochemical resistance.

The paper also highlights how the porosity of the foams can be adjusted by varying the size and wettability of the particular emulsifier. This also offers the opportunity to embed different functional materials into the surface.

Ongoing work is taking place to look into the use of a variety of particulate surfactants to measure their effect on the stability and properties of the resulting carbon foams, as well as to test the materials as possible electrodes in small supercapacitor devices.

Reference:

[Article co-written with Dora Olah an Undergraduate student in the Department of Chemical Engineering.]

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Michael Panagopulos

Department of Chemical Engineering