Welsh Centre for Printing & Coating Summer School

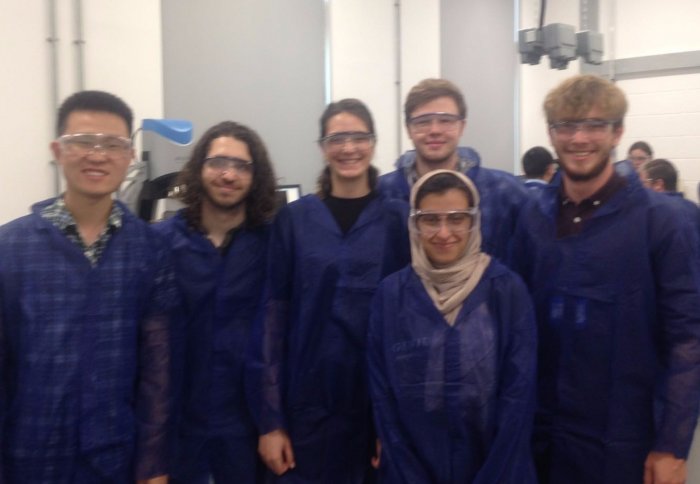

All the students in PE-CDT cohort 8 attended the Welsh Centre for Printing & Coating Summer School, which ran over 10th-14th July 2017.

Two students from Cohort 8, Joel Luke and Matyas Doboczi, report on their summer school experience...

Joel Luke

An appreciation of the scale up of plastic electronics is essential

– Joel Luke

PE-CDT Cohort 8 Student

The course provided the group with an introduction to printing technology and its application for functionalised materials, tying in with many research areas of the CPE. An appreciation of the scale up of plastic electronics is essential for young researchers in the field to ensure that the commercialisation of devices is realised.

Outside of the course the cohort enjoyed some team-building activities, and made the most of the unusually nice weather (Swansea is known for its rain!). One of the highlights was being taken to the picturesque beach of Rossilli Bay, by students from a Swansea based CDT that specialises in printing. The sea was even warm enough for a swim!

Matyas Daboczi

Taking part in The Welsh Centre for Printing and Coating (WCPC) summer school was a really great opportunity to learn about many of the printing processes used for functional materials and to broaden my knowledge about printed electronics. My work is related to perovskite solar cells, and although my project is not concerned with printing solar cells, the final aim of the whole research field is to realize highly efficient and stable solar cells that can be large area printed. So it was really useful to learn about all the available printing techniques.

On the first three days we had lectures on different printing techniques (3D, ink-jet, pad, aerosol jet, gravure, flexographic and screen printing) and about all the steps from ink formation to print characterisation that are relevant to the printing of functional materials. It was good to listen to some talks from invited speakers, who gave talks about the possible and some of the already realised applications of functional coatings (e.g. printed batteries, sensors, transistors etc.).

On the first three days we had lectures on different printing techniques (3D, ink-jet, pad, aerosol jet, gravure, flexographic and screen printing) and about all the steps from ink formation to print characterisation that are relevant to the printing of functional materials. It was good to listen to some talks from invited speakers, who gave talks about the possible and some of the already realised applications of functional coatings (e.g. printed batteries, sensors, transistors etc.).

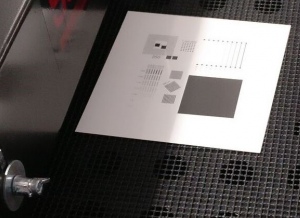

printed conductive patterns

The practical sessions of the last two days were extremely useful to understand all the theories we learned about (e.g. viscous fingering) and to actually see and fully understand the working principles of the large variety of printing processes.

Thanks to a networking event we also got the opportunity to look around the labs of SPECIFIC (Sustainable Product Engineering Centre for Innovation in Functional Coatings), which was for me one of the most interesting and relevant parts of the summer school as they are printing organic and also perovskite solar cells. It was great to have the chance to ask questions to those that are actually working on printing the same materials I’m working on.

It was also good to get to know and connect with, not just those working in Swansea, but some of the other participants. These included engineers and researchers from Thailand who are about to build a plant for the printing of perovskite solar cells.

It was also good to get to know and connect with, not just those working in Swansea, but some of the other participants. These included engineers and researchers from Thailand who are about to build a plant for the printing of perovskite solar cells.

Finally the summer school was a great chance to strengthen the bonds within our cohort, which might result in better cooperation in the future.

The cohort would like to thank those involved in organising and funding the trip, and enjoyed both the course and their time together in Swansea.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Dr Joel Luke

Department of Physics

Dr Matyas Daboczi

Department of Chemical Engineering