Young inventors turn ideas into reality in Imperial’s Maker Challenge

Young people from the White City area showcased their inventing and making skills as part of Imperial’s Maker Challenge.

Throughout the summer, pupils from local schools have been developing their own prototypes – from living walls to vacuum cleaner wind tunnels.

Based at the Reach Out Makerspace in The Invention Rooms at Imperial’s White City Campus, The Maker Challenge encourages young people from the local community to get hands-on by creating their own prototype products and gadgets.

Joint first place in this summer’s competition was awarded to Isaac Irudayaraj and Alice Szulc for their projects tackling climate change and giving pet owners a helping hand.

Living walls

Isaac’s project Plant Box is aimed at tackling climate change, focusing in particular on carbon capture. While plants are much cheaper and use less energy than current carbon capture technologies, Isaac argues that the lack of space in our cities is stopping people from planting.

Isaac is therefore aiming to make ‘living walls’ more accessible and cost effective, saying “if you can’t plant on the ground, then plant up.” According to Isaac, current vertical planting is expensive to build and often tailored to a specific project, meaning it’s not accessible to everyone. In addition they are difficult to maintain, often causing the plants to die, meaning they can’t fulfil their purpose.

Isaac is therefore aiming to make ‘living walls’ more accessible and cost effective, saying “if you can’t plant on the ground, then plant up.” According to Isaac, current vertical planting is expensive to build and often tailored to a specific project, meaning it’s not accessible to everyone. In addition they are difficult to maintain, often causing the plants to die, meaning they can’t fulfil their purpose.

Isaac has therefore created modular boxes to create living walls, focusing on making the product user-friendly, allowing customers to easily buy it from a shop and set up.

Food feeder

Alice’s project Food Feeder is a pet food bowl which dispenses food and water every several hours, as the owner chooses. This is aimed at people who are away from home for long periods during the day, therefore are unable to feed their pets at set times.

As part of the project, Alice has used an Arduino and written code that will open and close two trapdoors at specific times to allow the food and water to be dispensed into the bowls.

Building blocks

Second place went to Zenab Irshad with her project Stucco, an advanced  form of building block. This is inspired by brands such as LEGO and architectural puzzles to teach students the basic theories of architecture, such as the importance of shapes and levels, and develop cognitive skills through a creative, hands-on activity.

form of building block. This is inspired by brands such as LEGO and architectural puzzles to teach students the basic theories of architecture, such as the importance of shapes and levels, and develop cognitive skills through a creative, hands-on activity.

According to Zenab, other products are limiting as they may only focus on building one landmark for example.

Stucco on the other hand allows the user to experiment with each building block and learn why each building has its own distinct design.

Vacuum wind tunnel

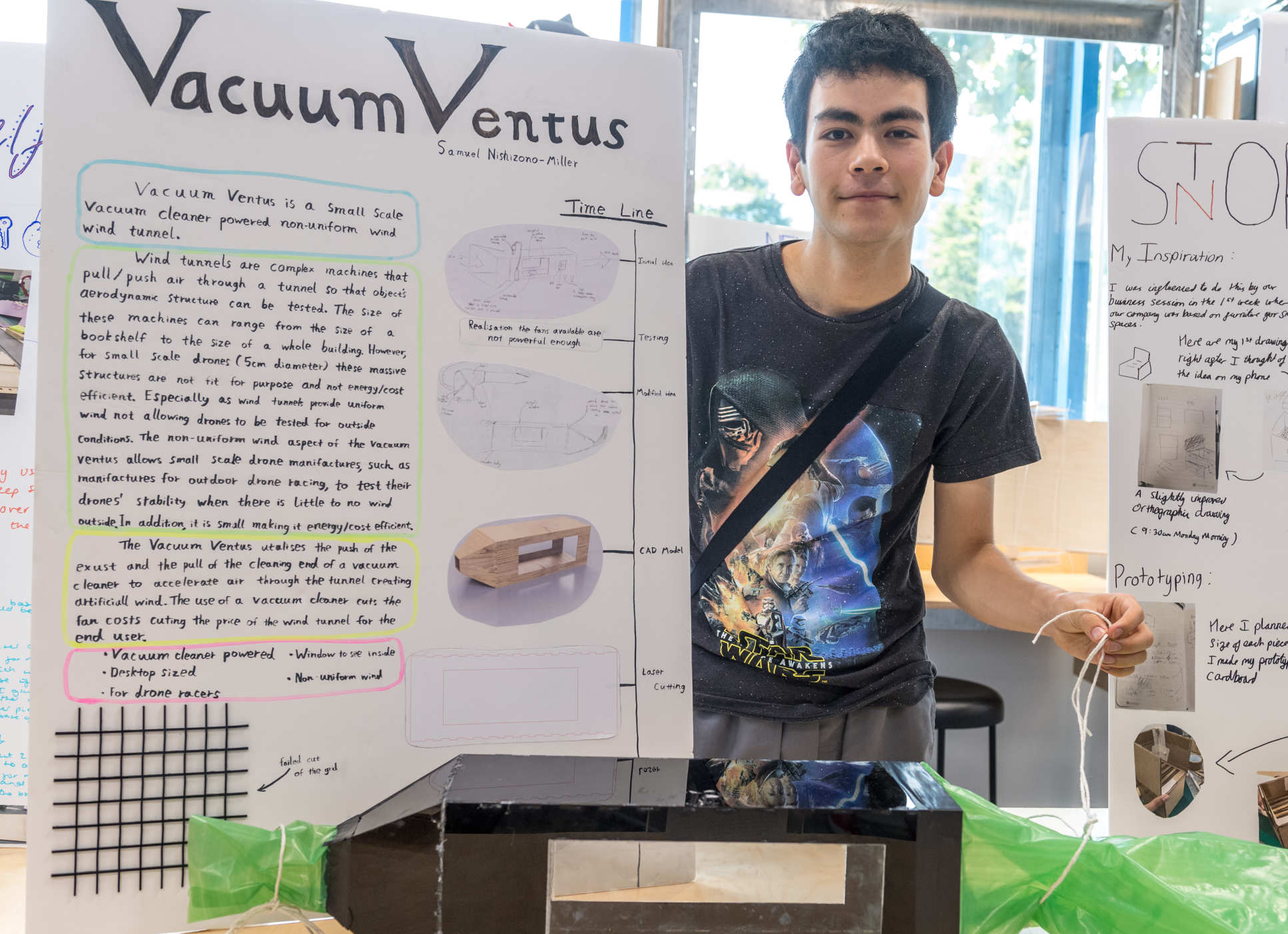

Third place went to Samuel Nishizono-Miller and his project Vacuum Ventus, a small-scale wind tunnel powered by a vacuum cleaner. Wind tunnels, used to test an object’s aerodynamic structure, vary in size however according to Samuel, most are too large for small-scale drones (around 5cm diameter) and are also not energy or cost efficient. Wind tunnels also provide uniform wind, which does not replicate the conditions a drone would experience outside.

The non-uniform wind in Samuel’s tunnel would allow small-scale drone manufacturers, such as those used for outdoor drone racing, to test their drones’ stability when there is little to no wind outside.

The tunnel uses the push of the vacuum cleaner’s exhaust and the pull of the cleaning end to accelerate air through the tunnel, creating artificial wind. The use of a vacuum cleaner also makes the small wind tunnel both energy and cost efficient.

Ideas to reality

Throughout the programme students gain a range of skills from use of 3D printers and laser cutters, to product development, team-building, and presentation and communication skills to help turn their innovative ideas into reality.

Other projects this summer included a bookshelf with adjustable bookends, a music stand that turns the page itself, a portable water cooler and hanging shelves.

The programme came to an end with a final showcase, where the projects were judged by a panel of experts.

The judges were Dr Melanie Bottrill (Imperial College London), Dr David Miller (Imperial College London) and Karsten Goodwin (Production Designer at Random International).

Image credits: Fergus Burnett

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Joanna Wilson

Communications Division