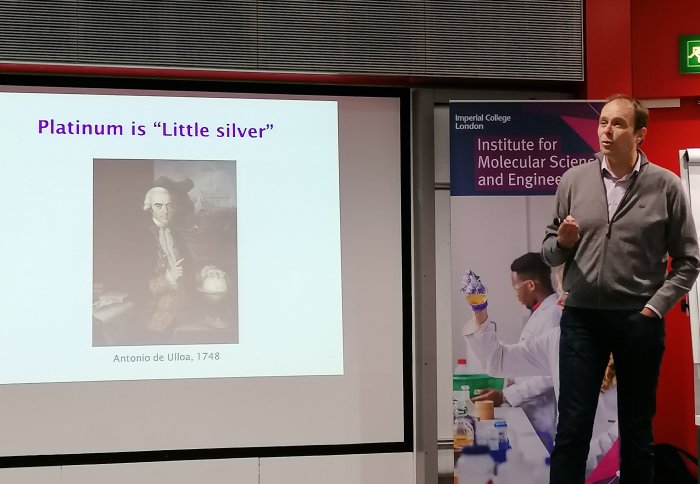

Electrochemistry of platinum: new views on an old problem

Marc Koper gave the latest IMSE Highlight Seminar on the electrochemistry of platinum, vital in a new generation of renewable energy devices

Devices such as fuel cells could drive the world's decarbonisation, and one of the key metals used in fuel cells is platinum.

Due to its hardiness, platinum is widely used in the electrodes of fuel cells that convert hydrogen and oxygen into water and electricity. However with use, the smooth platinum electrodes roughen and wear, causing nanometer-scale mounds to grow. Mysteriously, this enhances the electrode's performance.

How can we image platinum at atomic scales?

Electrochemist Marc Koper from the University of Leiden, works with a team of scientists to discover how platinum behaves after extensive use in fuel cells. Recently he gave a seminar at Imperial as part of the Institute for Molecular Science and Engineering's Highlight Seminar series. In his seminar, Professor Koper highlighted the recent work of his group in understanding the surface chemistry of platinum.

It was assumed that repeated cycles cleans the electrode, but this is certainly not the only thing happening. Marc Koper Professor of Catalysis and surface chemistry, University of Leiden

Before it works optimally, the platinum electrode has to undergo several cycles of oxidation and reduction. Chemical and physics research has shown how repeatedly oxidising and reducing roughens the platinum, but the exact mechanism behind this process has always been somewhat of a mystery.

In an earlier paper, Professor Koper and his team showed that the roughening can be imaged to almost atomic resolution with a special Scanning Tunneling Microscope.

Platinum mounds

In his Highlight Seminar, Professor Koper outlined how the Scanning Tunneling Microscope scans the surface, measuring an extremely small current. This so-called tunnelling current is used to image the surface atomically.

The technique shows how growing mounds form on the platinum surface. Initially, a perfect platinum surface is a plane of platinum atoms in a neat hexagonal lattice. When this surface oxidises, a one atom thick layer of platinum oxide forms. In order to fit in the extra oxygen atoms, some platinum atoms are pushed out of the surface, and these atoms start to wander over the surface. These wandering atoms are called adatoms. During their travels, adatoms run into other adatoms, and they stick together to form small islands.

A surprising result

The wear and roughening of platinum electrodes is the most important factor in their longevity, by understanding the process we can improve performance. Professor Marc Koper Professor of Catalysis and surface chemistry, University of Leiden

When the platinum oxide layer is subsequently reduced, the adatom islands stay behind, along with the empty oxygen spots in the layer below, called vacancies. With repeated oxidizing and reducing, mounds start forming made out of stacked plateaus. The mounds become higher in the middle and deeper at the edges. This was a surprising result for Professor Koper's team as it was previously thought that mounds should not be stable, and would merge together.

According to Professor Koper, the growing holes and mounds nicely explain the evolution of the mounds and thus the observed roughness.

MRes in molecular Science and Engineering

Professor Koper also took time out of his busy schedule to meet some of the student's on the MRes in Molecular Science and Engineering course.

This new MRes (Master’s in Research) programme trains science and engineering graduates through a combination of taught modules and a research project with industry.

Students asked Marc questions about his own career and research interests.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Dr Kieran Brophy

Faculty of Engineering