A novel micro-pneumatic tool for targeted therapy and cell-based intervention

Hamlyn Centre researchers proposed a novel micro-pneumatic tool with actuators at the capillary tip, aiming to aid clinical cell-based interventions.

With increasing demand for targeted therapy and cell-based intervention, such as endovascular applications, there is a growing interest in the development of new micro-tools that can be used for in situ and in vitro applications.

Yet, scaling down and assembling conventional tendon-driven surgical tools become infeasible when below a few hundred micrometers due to increasing surface friction forces.

On the other hand, bring actuation to micro-scale tethered tools has been suggested as an alternative solution since micro-scale tools with electromechanical actuators necessitate a large actuator footprint and can have a relatively low output power.

Some approaches have been proposed by using magnetic forces to actuate catheters and other medical tools with an external magnetic field.

However, one major drawback of these magnetic methods is the rapid decay of the field gradient with distance, which requires electromagnets of several centimetres placed close to the gripper or within a magnetic resonance imaging machine, in order to achieve sufficient force at such smaller scales.

Liquid seal for compact micro-piston actuation at the capillary tip

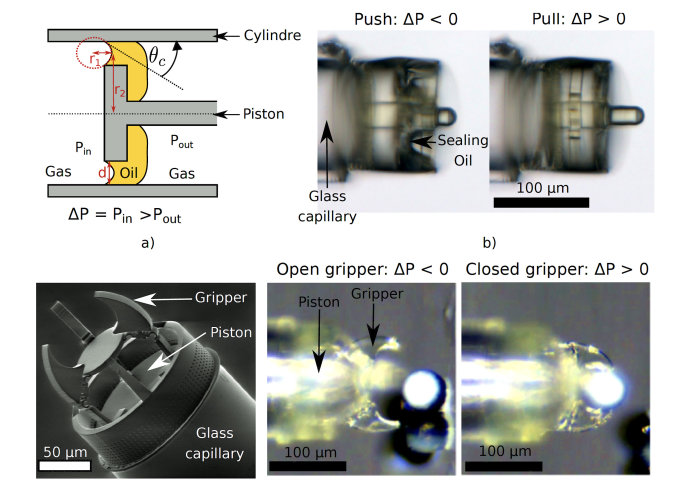

To provide actuation at the scale of a few hundreds of micrometers without having those issues while using magnetic force at this scale, our researchers at the Hamlyn Centre proposed a novel approach with the combination of pneumatic actuation and surface tension to drive a piston that is attached to the distal end of a 140-μm-diameter glass capillary.

The translational motion of the piston could serve as the basis of many different micro-mechanisms such as biopsy grippers, targeted delivery systems, and single-cell manipulation or for the orientation of micro-optics on micro-catheter tips.

In this work, a micro-gripper is chosen to demonstrate the usability of the micro-piston. A 2PP direct laser writing system (Photonic Professional GT, Nanoscribe) was used to fabricate the micropiston and gripper onto the end of the glass capillary.

Furthermore, an oil drop method is used to create a seal between the piston and the cylinder that prevents any leakage below 185-mbar pressure difference while providing lubricated friction between moving parts.

One advantage of pneumatic actuation is that the achievable forces remain relatively large at micro-scales. This piston generates forces that increase linearly with pressure up to 130 μN without breaking the liquid seal.

The practical value of the design is therefore demonstrated with its integration with a micro-gripper that can grasp, move, and release 50-μm microspheres.

Overall, our researchers have demonstrated that such micro-piston could provide the actuation mechanism to drive a micro-tool at the tip of a catheter. They realised a compliant gripper and demonstrated the grasping, ran-sport, and release of a 50-μm microsphere. Such pneumatic mechanisms could find many applications for micro-catheters in surgery.

This research was supported by EPSRC Programme Grant “Micro-robotics for Surgery (EP/P012779/1)” and was published in Science Advances on 27th May 2020 (Antoine Barbot, Maura Power, Florent Seichepine and Guang-Zhong Yang, "Liquid seal for compact micropiston actuation at the capillary tip", Science Advances, 6 (22), May 2020).

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Erh-Ya (Asa) Tsui

Enterprise