New membrane could cut emissions and energy use in oil refining

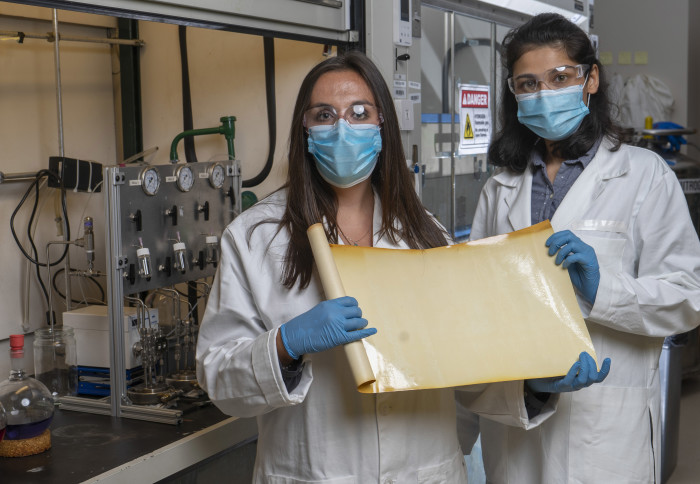

The membrane at Georgia Tech

Imperial has co-developed the first synthetic membrane to separate crude oil and crude oil fractions, which could help reduce carbon emissions.

Crude oil is refined to create fuels like diesel, petrol and jet fuel, as well as lubricants and plastics. However, the processes used to create these byproducts are a major source of pollutants to the air, water, and soil. It is also a large-scale, energy-intensive process that accounts for nearly one per cent of the world’s energy use.

Now, a new membrane developed by researchers from the Georgia Institute of Technology, Imperial College London, and ExxonMobil could help reduce carbon emissions and energy use associated with refining crude oil.

By substituting the low-energy membranes for certain steps in the refining process, the new technology might one day contribute to a hybrid refining system that could help reduce carbon emissions and energy consumption significantly compared to traditional refining processes.

The researchers say that, although additional research and development will be needed to advance this to an industrial scale, the new membrane could replace some conventional heat-based refining processes in the future.

The findings are published in Science.

Membrane technology

We worked extensively with ExxonMobil and Georgia Tech to test how we could advance our membranes to the levels required by the petroleum industry. Professor Andrew Livingston Department of Chemical Engineering

Membranes separate molecules from mixtures according to size and shape. When molecules are similar in size, that separation becomes more challenging.

Membrane technology is already widely used in applications like seawater desalination, but the complexity of petroleum refining has until now limited the use of membranes. To overcome this challenge, the research team applied a new polymer to a surface to create membranes able to separate the complex hydrocarbon mixtures that make up crude oil through the application of pressure rather than heat.

The team balanced a variety of factors to create the right combination of solubility, which enables membranes to be formed by simple and scalable processing, and structural rigidity, which allows some small molecules to pass through more easily than others.

The researchers found that the materials needed a small amount of structural flexibility to improve size discrimination, as well as the ability to be slightly ‘sticky’ toward certain types of molecules that are found abundantly in crude oil.

After designing the novel polymers and achieving some success with a synthetic gasoline, jet fuel, and diesel fuel mixture, the team decided to try to separate a crude oil sample and discovered that the new membrane was effective at recovering gasoline and jet fuel from the complex mixture. The polymers were designed and tested at Georgia Tech, then converted to 200-nanometer-thick films and incorporated into membrane modules at Imperial.

Co-author Professor Andrew Livingston, of Imperial’s Department of Chemical Engineering, said: “Our team already has experience bringing membrane technology to market, with our previous invention of organic solvent nanofiltration, which is becoming widely adopted in the pharmaceutical and chemicals industries.

“We worked extensively with ExxonMobil and Georgia Tech to test how we could advance our membranes to the levels required by the petroleum industry.”

The research team also created an innovation pipeline that extends from basic research all the way to technology that can be tested in real-world conditions.

Co-author Dr Kim Jelfs of Imperial's Department of Chemistry said: ”We have been using an approach to build molecular models of membranes that explain their separation behaviour, and here we applied this to understand why certain molecular systems gave better performance than others. The advantage of our models is that they allow a molecular level understanding of the structure-property relationships involved."

Professor M.G. Finn, also of Georgia Tech, said: “This membrane technology could make a significant impact on global energy consumption and the resulting emissions of petroleum processing.”

“N-Aryl Linked Spirocyclic Polymers for Membrane Separations of Complex Hydrocarbon Mixtures” by Thompson, et al., published 16 July 2020 in Science.

This news story was adapted from a press release by Georgia Tech.

Images

1 (main): Georgia Institute of Technology; 2. Irene Bechis; 3. Imperial; 4. Imperial; 5. Shutterstock

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Caroline Brogan

Communications Division