New peptide manufacturing method could produce cheaper medicines

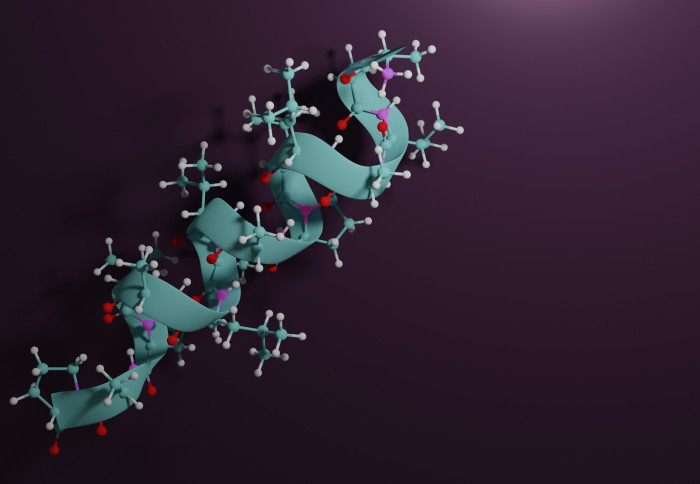

Scientists have developed a new method of synthesising peptides which could improve the efficiency of drug manufacturing processes.

Over 70 different peptide drugs are approved for clinical use and used to treat a range of illnesses including diabetes, cancer and HIV, with more drugs currently in development. An increase in the number of available peptide treatments means that peptide manufacturing technology will need to adapt to in order to meet future manufacturing demands.

This new technique developed by scientists at Imperial College London, known as PEPSTAR, provides an efficient way to speed up the process of peptide synthesis without compromising on quality. It has the potential to be scaled-up for commercial use and could be extended to the production of other sequence-defined polymers in a variety of applications.

The research has been published in Angewandte Chemie.

Solid and liquid challenges

Peptides must be built from an exact sequence of amino acids, so the ability to remove any excess amino acids that are not part of the sequence before adding another is a crucial step in the manufacturing process.

"PEPSTAR is a more flexible platform compared to the classic solid phase method, and it provides more options for further optimisations of the peptide manufacturing process." Professor Andrew Livingston Department of Chemical Engineering

Currently, most peptide drugs are manufactured using the solid phase method, which couples amino acids to insoluble solid supports and then washes away any excess amino acids from the support-bound growing peptides after coupling. The main advantage of this method is that it can be easily automated to enable rapid synthesis in a single reactor.

However, the solid phase method is challenging to scale-up. There are “diffusional limitations” in the solid supports, where amino acids need to diffuse towards the interior of the solid resin beads to couple. These limitations can cause incomplete reactions, leading to low peptide purity. Excess reagents have to be used to ‘drive’ the reactions to completion, which makes the process more costly and less efficient.

One way to address these challenges is by using the liquid phase method instead. In this method, the supports that the amino acids are attached to are soluble, and the peptides are all grown by coupling amino acids one after another to the soluble supports in liquid phase. This removes the problem of diffusional limitations so that the purity of the peptides produced is greater, and there is less need for using excess reagents to drive the reactions to completion.

However, the liquid phase method has so far been hampered by slow and complex extraction or precipitation methods. These methods typically require support-bound growing peptides to be transferred between apparatus or isolation via a phase transfer (e.g. liquid to solid) during different cycles of the process. Material and phase transfers make the liquid phase method challenging to scale-up or automate.

PEPSTAR of the show

In collaboration with Eli Lilly and the University of KwaZulu-Natal, a team in the Department of Chemical Engineering’s Livingston Group have developed PEPSTAR, a “one pot” liquid phase method that is able to isolate growing peptides using a process called organic solvent nanofiltration (OSN), which filters out any reaction debris and isolates the growing peptides without any phase or material transfers between cycles.

A typical PEPSTAR synthesis cycle involves:

- coupling the amino acid to a “nanostar” support;

- removing the Fmoc protecting group;

- quenching, and

- filtering out the reaction debris through a membrane to effect “nanostar sieving”

In their research, the team used the PEPSTAR platform to successfully synthesise a range of short peptides (5-10 amino acids). They found that these peptides had higher purity and could be synthesised at half the cost of standard samples produced using the solid phase method.

A promising future for PEPSTAR

Principal Investigator Professor Andrew Livingston said: “PEPSTAR is a more flexible platform compared to the classic solid phase method, and it provides more options for further optimisations of the peptide manufacturing process. This has the potential to drive the cost of peptide drugs down and make them more widely accessible to patients.”

"This novel approach offers not only a new paradigm for peptide synthesis, but is also applicable across the synthesis of other high-precision polymers". Jet Yeo Department of Chemical Engineering

While the method has only been used for shorter peptides so far, researcher Jet Yeo anticipates that making a few changes to the process could allow for very long peptides (chains of more than 20 amino acids) or proteins (chains of more than 50 amino acids) to be produced using PEPSTAR in the future.

This is particularly exciting, because it means that PEPSTAR could be used for synthesis in other processes too. Co-author Jet Yeo explained: “This novel approach offers not only a new paradigm for peptide synthesis, but is also applicable across the synthesis of other high-precision polymers such as oligonucleotides, polyesters, and polyethylene glycols.” These high-precision polymers have applications in many areas, such as genetic testing, forensics and medicine.

-

'Liquid Phase Peptide Synthesis via One?Pot Nanostar Sieving (PEPSTAR)' by Jet Yeo et al is available in Angewandte Chemie.

Funding provided by Engineering and Physical Sciences Research Council, Grant Number: MO1486/X and Eli Lilly and Company, Grant Number: Research Award Programme.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Press Office

Communications and Public Affairs

- Email: press.office@imperial.ac.uk