3D-printed Sensor on Fibre-Optic Probes for Rapid Bacteria Detection

The Hamlyn Centre research developing miniature fibre-optic probes for label-free bacteria detection was recently featured by Nanoscribe.

- Nanoscribe featured article, highlighting their new commercially available approach for on-fibre printing: On-fibre printed sensor for label-free detection of bacteria

World Health Organization (WHO) identifies antibiotic resistance as one of the greatest threats to global health, food safety and development. The high use or misuse of antibiotic treatments could accelerate the evolutionary process of bacterial immunity. There is therefore a great need to develop more precise treatment towards infections, such as in-situ characterisation of the infected region.

Raman spectroscopy is a powerful analytical technique that has been spotlighted for detection and diagnosis of diseases ranging from infection to cancer. However, as Raman signals are usually weak and can easily be swamped by interfering background signals, deploying Raman spectroscopy can be very challenging in the clinic.

"One solution to enhance the signals generated from Raman spectroscopy is to metallise the surfaces with micro- and nanoscale structures. This significant signal enhancement effect is known as surface-enhanced Raman spectroscopy (SERS)", lead researcher, Dr Jang Ah Kim explained. Yet, developing miniature fibre-optic SERS probes can be problematic and requires advanced micro-fabrication technologies.

3D-printed Sensor on Fibre-Optic SERS Probes for in-situ Bacteria Characterisation

To tackle these issues, researchers in the Hamlyn Centre developed a fibre optical sensor for the label-free detection and characterisation of bacteria, along with a new protocol for simple, effective and reliable fabrication of miniature fibre-optic SERS probes. This novel miniaturised optical sensor can potentially be integrated into medical endoscopes for in-situ analysis of inflamed tissue.

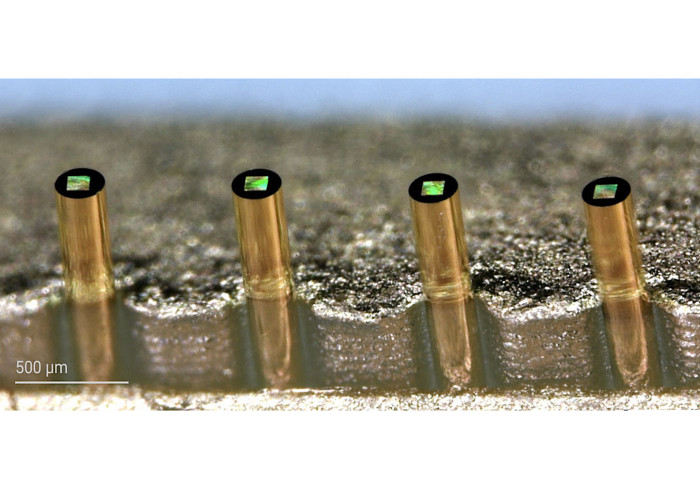

Our research team first 3D-printed polymer micro- and nano-structures on the tip of an optical fibre by using two-photon polymerisation (2PP), a micro-scale 3D-printing technique that is commercially available (Nanoscribe GmbH, Germany). These micro- and nano-structures then coated with a thin layer of gold (50 nm) to produce the metal surfaces for Raman signal enhancement.

The fibres used are only 220 µm in diameter—roughly 2-3 times the thickness of a single strand of hair. Working on a such small spacing distance on the tip of an optical fibre, our researchers demonstrated that it is feasible with 2PP-based micro-fabrication and that the proposed technique is reliable and reproducible.

Dr Alexander Thompson said: "In this study, we further demonstrated the capability for rapid detection of bacteria in solution by optimising the microstructures and characterising the sensing performance of the probes."

"To our knowledge, this is the first report of detection of live, unlabelled bacteria using a fibre-optic SERS probe. The research results indicated the future potential for clinical applications", Dr Jang Ah Kim emphasised.

This research was conducted as a part of EPSRC Programme Grant, “Micro-robotics for Surgery (EP/P012779/1)” and was published in the early view of Advanced Optical Materials this week (J. Kim, D. J. Wales, A. J. Thompson, G.-Z. Yang, “Fiber-Optic SERS Probes Fabricated Using Two-Photon Polymerization For Rapid Detection of Bacteria”, Advanced Optical Materials 2020, 1901934).

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Erh-Ya (Asa) Tsui

Enterprise