Aeronautics student wins competition with novel blade design

by Ayesha Khan

PhD Candidate, Adam Whitehouse, wins national competition with unique blade design that could transform aviation and wind energy industries.

Aeronautics’ PhD student Adam Whitehouse has emerged the winner of the recent Society for the Advancement of Material and Process Engineering (SAMPE) UK and Ireland Seminar Competition.

Adam presented his novel blade leading edge concept that allows for increased blade strength and longevity, as well as enabling lighter blades for reduced fuel consumption and costs.

On the win Adam said: "It was really exciting to win this competition and to receive such positive feedback on the work, from both the judges and those in industry attending the conference. It was very assuring to see such interest in my work from professionals who may apply concepts like this in real world applications."

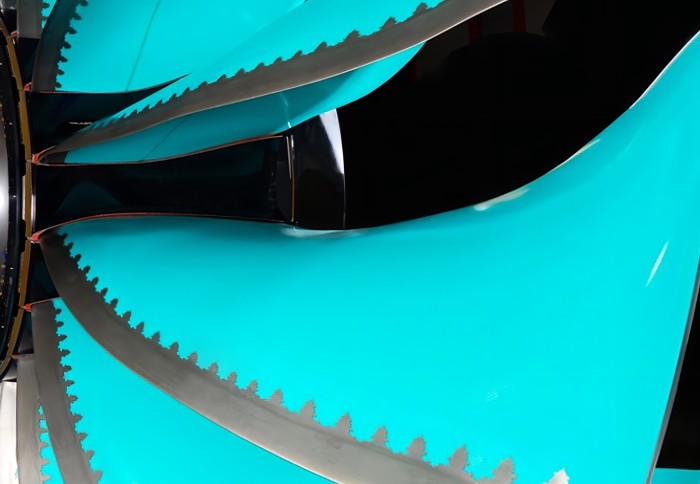

Jet engine blades

Bird strikes are a serious safety concern for the aviation sector, as they often lead to significant damage.

The stiffness difference between a composite blade and a metallic erosion shield concentrates stresses along the leading edge, making blades more susceptible to this damage and to ultimate failure.

To prevent and protect against such damage, traditional composite blades are overdesigned, which results in heavier blades that are more costly and increase fuel consumption.

Wind turbine blades

The same problem is encountered by larger offshore wind turbines, which are seeing a pattern of erosion failure a few years into their supposed 25-year service life.

A metallic erosion shield could be used to address this, but the stiffness difference problem needs to be addressed.

Novel erosion shield

Adam’s research, alongside supervisor Professor Silvestre Pinho, co-supervisors Dr Victor Médeau and Dr Lorenzo Mencattelli, and in collaboration with Professor Bamber Blackman, looks to find a resolution by employing a fractal edge to the metal-composite adhesive joint.

A profiled edge as such allows for distributed stresses and improves failure stability by deflecting cracks.

Such advancements could be used to help the sustainability mission as explained by Professor Silvestre Pinho: "This technology will help in our transition to NetZero. In aviation, it can help make engine blades lighter, which becomes even more important as we move towards alternative fuels. In wind energy, it can help increase the longevity of wind turbine blades, which is fundamental given the difficulty in recycling them." Experimental data, conducted at Imperial, has shown that this concept significantly improves performance, and that adjustments to the size and complexity of the profile provide enhanced results, making it a promising solution for improved performance of industrial components such as jet engine blades and offshore wind turbine blades.

Experimental data, conducted at Imperial, has shown that this concept significantly improves performance, and that adjustments to the size and complexity of the profile provide enhanced results, making it a promising solution for improved performance of industrial components such as jet engine blades and offshore wind turbine blades.

Adam’s success of being awarded ‘Best Presenter’, at national level allows him to progress to participate in the European Students’ Seminar competition, which will be held at the SAMPE Europe Conference in Spain.

Adam’s work is published in Composites Part B: Engineering.

Feature image adapted from ©Rolls-Royce plc.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ayesha Khan

Department of Aeronautics