New industry partnership to research crystallisation processes

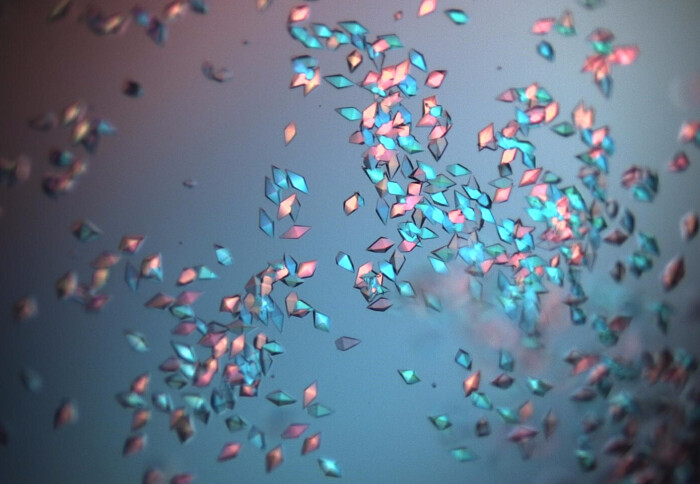

A scatter of tiny crystals of proteins, mostly roughly octahedral in shape.

Imperial College London partners with chemical company BASF and other universities to research crystallisation processes for sustainable manufacturing

Imperial College London has partnered with chemical company BASF, the University of Manchester and Curtin University in a new worldwide Crystallisation Cluster. The cluster will develop both computational and experimental research to understand and control crystallisation processes for sustainable manufacturing.

Crystallization is one of the most important unit operations in the chemical industry. However prediction and scale-up are difficult and often require a lot of costly and time-consuming experimental work. Combining computational approaches with experimental data can reduce costs and increase precision.

Crystals are central to environmental processes

Crystals and crystallisation are fundamental in nature. They are also in many of the functional materials that we use in our everyday life.

A natural example are the calcium carbonate crystals found in seashells. These are a major sink for the greenhouse gas carbon dioxide. Human-made examples include the silicon components that drive computers, pharmaceutical compounds products for health, and agrochemicals that ensure a safe and abundant food supply.

These materials are made up of micron-sized crystals (one thousandth of a millimetre in length). In these crystals, atoms and molecules are ordered in beautiful repeating arrays.

Crystals are central to industrial processes

In industry, controlling the shape and size of crystals are essential to ensuring, for instance, the purity and stability of drugs, the reliability of batteries and the strength of metals and concretes.

Dr Lars Matthes, Research Scientist at BASF, said: “In industry, the parameters of the crystallisation process strongly influence the properties and performance of the products. However we only partly understand the underlying relationships between process and product. This leads to a considerable experimental effort to improve a process towards a certain target outcome. We expect that the innovative computational and experimental approaches developed in this collaboration cluster can significantly contribute to better process and product optimization.”

“Improved control of crystallisation at the nanoscale is central to sustainable and reliable production. From pharmaceuticals to catalysts and low carbon concrete, it is the control of initial crystal growth that is vital,” said Nicholas Harrison, Professor of Computational Materials Science at Imperial College London.

Combining computational and experimental research

Jerry Heng, Professor of Particle Technology at Imperial College London, said: “We are excited to be part of this unique collaboration between experimental and modelling groups in academia and BASF. We will be developing fundamental understanding of crystal growth. Our experimental data is used as input to modelling and computational work guides our experiments. The potential impact of this research is to manufacture crystalline particles which are optimised for their application, and to do this sustainably.”

Mike Anderson, Professor of Materials Chemistry, University of Manchester, said: “Controlling how crystals grow in the laboratory in terms of crystal purity, crystal size and shape and crystal structure is key to developing materials for the 21st century. In Manchester we are using state-of-the-art microscopy tools to monitor how crystals grow at the atomic scale. This is combined with modelling software developed through our spin-out company CrystalGrower to design new processes that our partners such as BASF can introduce into their workflows.”

Improving sustainability

Currently, production, distribution and consumption worldwide are changing to more sustainable processes. In this transition, crystallisation has emerged as one of the areas where revisiting the underlying science is essential. Better understanding of crystal processes could reduce demand for raw materials, solvents and energy. It could also reduce waste and increase yield. All of these changes increase the sustainability of industrial processes.

The Imperial team is lead by the Institute for Molecular Science and Engineering (IMSE), which is directed by Professor Amparo Galindo and Professor Nicholas Harrison. IMSE was founded in 2016. It promotes multidisciplinary approaches to global challenges. IMSE’s Affiliates combine molecular and experimental approaches, and investigate questions of scaling from the molecular to the industrial.

Dr Christian Holtze, Academic Partnership Developer at BASF, said: “When setting up our research cluster on crystallization, we realized that combining Mike Anderson’s expertise at University of Manchester with that at IMSE has the potential to revolutionize our industrial R&D workflow in crystallization. The cluster is a prime example of how to combine cutting-edge digital and experimental research in an interdisciplinary and cross-organizational setup. At the same time this requires a great deal of openness from every individual involved. In our bi-weekly telephone conferences and in a face-to-face crystallization conference in Ludwigshafen, Germany, in Autumn 2022, we felt how our collaborators at IMSE embrace and foster the opportunities of working with researchers at other top-notch institutions in academia and industry.”

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Dr Isabella von Holstein

Department of Computing