Undergraduate students reflect on placements in industry

Students in the Department of Materials have reflected on their placements in industry.

An Industrial Placement is a work experience opportunity where undergraduate students are able to gain practical experience in industry over the summer break or for a whole year. These placements are organised independently.

Students from the Department of Materials have completed a variety of industrial placements with companies this year, such as the UK Atomic Energy Authority, Airbus and Mercedes.

Karen Pacho Dominguez, UK Atomic Energy Authority

Karen completed a three-month summer internship in at the Culham Centre for Fusion at the UKAEA (UK Atomic Energy Authority). She is currently a fourth-year undergraduate student in the Department of Materials.

Karen completed a three-month summer internship in at the Culham Centre for Fusion at the UKAEA (UK Atomic Energy Authority). She is currently a fourth-year undergraduate student in the Department of Materials.

The Culham Centre for Fusion at the UKAEA houses the Joint European Torus (JET) and holds the world record for the longest fusion pulse in a tokamak. Karen's project investigated where and why hydrogen retention occurs in metallic structural materials of tokamak reactors.

Tritium is a radioactive isotope of hydrogen, so tracking it is a legal requirement for safety and non-proliferation. Significant retention of tritium in structural materials will be detrimental to the economics of any future powerplant. Karen's task was to design characterisation experiments around 316 stainless steel that will be exposed to hydrogen plasma.

During her placement, Karen produced literature reviews on retention mechanisms, characterisation techniques and the work of other plasma exposure devices. She also spent considerable time preparing metallographic samples and using SEM. She also helped to commission scintillation equipment to support the site's health physics protocols run more smoothly. Karen also learned and performed simulations for ion damage in materials using different models.

She comments: "I am most grateful to have met such a wide range of knowledgeable and accomplished people who were eager to share their expertise and invaluable advice, which will undoubtedly shape my career.

It was so fulfilling to be able to use everything I learnt from all three years of my degree so far to aid their work!"

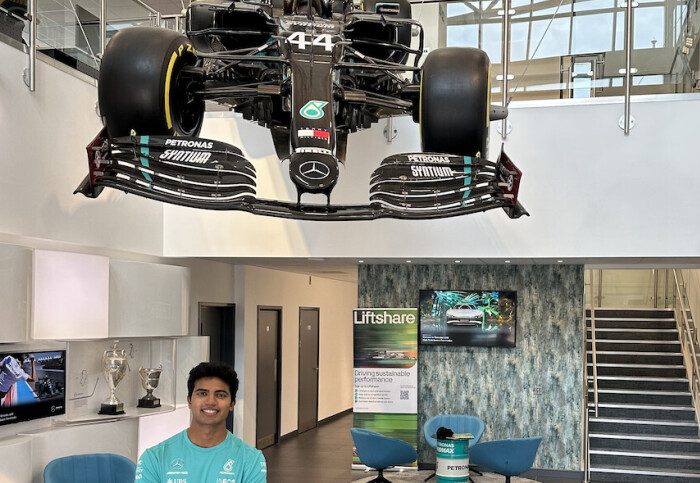

Abhi Rajendran, Mercedes AMG

Abhi completed a year-long placement at Mercedes AMG High-Performance Powertrains, who are responsible for developing and manufacturing the engines for the Mercedes AMG Formula 1 Team.

Abhi completed a year-long placement at Mercedes AMG High-Performance Powertrains, who are responsible for developing and manufacturing the engines for the Mercedes AMG Formula 1 Team.

Abhi worked on a wide range of failure investigations across the entire F1 Power Unit and on a few chassis side components, the most dramatic of which had come straight from the track for a root cause to be diagnosed before racing again.

The Research & Development work that Abhi completed was mainly spread across two main projects – the first project focused on the development of thermal interface materials for use within the internal combustion engine intended to meet the 2026 regulations. The second was researching manufacturing soft magnetic cores for use in the KERS (kinetic energy recovery system).

Abhi comments: "Probably the quickest timelines for projects in an engineering company with design, manufacturing, assembly and validation all under one roof, it was a great place to gain a wide exposure to the full lifecycle of a product."

Geronimo Lauzan, Tenaris

Geronimo completed a two-month summer internship in the Research & Development department of Tenaris in Buenos Aires, Argentina. He is currently a second-year undergraduate student in the Department of Materials.

Geronimo's project focused on developing coatings to delay the permeation of hydrogen through steel. His responsibilities included refining methods for measuring hydrogen permeation, such as coating samples with Pd, changing O-rings' materials, and creating a detailed manual for assembly, disassembly, pressurization, and depressurization of the permeation chamber.

Geronimo comments: "One of the most rewarding aspects of the internship was putting all the knowledge I had gained throughout the academic year into practice.

I could see firsthand how valuable the development and application of that knowledge was in a competitive field.

I think this internship has not only given me a lot of practical knowledge in the industry's know-hows but has also taught me a lot about the dynamics in these environments, which I think will be incredibly useful so I can hit the ground running in whatever future job I may have."

Masaki Nakamura, Ceres Power

Masaki completed a three-month summer internship at Ceres Power UK. He is currently a third-year undergraduate student in the Department of Materials.

Masaki completed a three-month summer internship at Ceres Power UK. He is currently a third-year undergraduate student in the Department of Materials.

Masaki's worked on a lab research investigation and synthesis of ceramic materials for an anode and an electrolyte of Ceres SteelCell™, which is a highly efficient, fuel-flexible, robust and economical solid oxide fuel cell (SOFC) and can be used in a wide range of industry applications to decarbonise industry including, distributed power, motive, and marine.

His project investigated the fundamental understanding of powder properties to improve in-house powder rheology and performance. To achieve this, Masaki designed a series of experiments and established procedures to characterise the behaviour of powder samples.

Masaki commented: "Through designing a series of experiments to establish a powder evaluation method, I’ve gained confidence in conducting experiments independently and in tackling real-world problems which are challenging, yet intriguing.

I also honed my wet lab skills, particularly chemical handling, safety management, and experimental design, through the synthesis of ceramic particles.

What I enjoyed the most during my internship at Ceres was working with the people at Ceres. They are really friendly, and I loved working with like-minded colleagues as we strive towards a decarbonised future with SOFC technology!"

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Kayleigh Brewer

Department of Materials