AI spinout Polaron shortlisted for £1 million Manchester Prize

by Ian Mundell

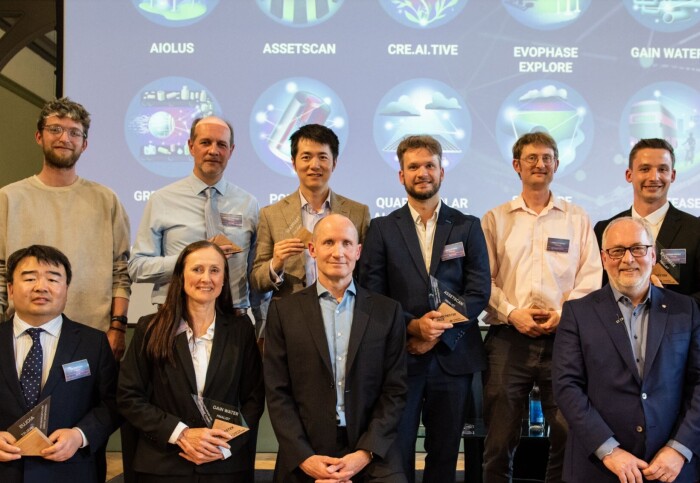

Dr Steve Kench of Polaron (top left) at the announcement of Manchester Prize finalists

Method for optimising advanced materials production, based on Imperial research, is chosen as an example of AI for the public good.

Imperial spinout Polaron has been shortlisted for the inaugural Manchester Prize, a government-run competition supporting breakthroughs in artificial intelligence for the public good. Each of the ten teams shortlisted has been awarded £100,000 to develop their solutions further, with one of the finalists set to receive a grand prize of £1 million next spring.

It’s really exciting to be in an ecosystem where we get to interact with other great AI startups. Isaac Squires Polaron

“The Manchester Prize gives us a huge boost in visibility, and it’s really exciting to be in an ecosystem where we get to interact with other great AI startups,” says Isaac Squires, Polaron’s chief executive and part of the founding team from the Dyson School of Design Engineering.

In addition to the prize money, the shortlisted companies benefit from a comprehensive support package, including funding for computing resources, investor readiness support, and access to a network of experts.

“The whole AI space is so dynamic at the moment, and moving so quickly, that you benefit massively from being part of a community that knows what the most exciting new tools are, and how to deploy them,” says Dr Sam Cooper, another co-founder of Polaron and the company’s chief scientist.

Optimising materials production

Polaron was set up earlier this year to develop generative machine learning algorithms based on Imperial research that could accelerate the design of advanced materials for applications such as batteries and high-performance alloys.

“Lots of AI companies are trying to do materials discovery, promising to find the next battery cathode material, for example, or the next solar panel,” Dr Cooper says. “Polaron is doing something different. We’re optimising the products that a manufacturer can already make with its existing production line and materials, which is an approach that allows industry to move forward much more quickly.”

The conventional way of approaching this kind of process optimisation is a mix of engineering instinct and rules-of-thumb about what works. However, this trial-and-error approach can take years as the design space is vast.

Polaron is optimising the products that a manufacturer can already make with its existing production line and materials." Dr Sam Cooper Polaron

Polaron is transforming this material design approach by learning the relationship between the microscopic structure of a material and the way it is made, directly from image data. These models enable a rapid exploration of the possible designs, taking the design cycle down from hundreds of weeks to hundreds of hours.

“We are using image data of the material microstructure to train our models,” says Dr Steve Kench, Polaron’s third co-founder and chief technology officer. “This can help us connect the way the material is made to how it behaves, and rapidly design materials with the best performance, whether that is how fast your battery can charge up, how much energy it can store, or how much it costs to produce.”

The potential gains are significant, with optimisation capable of yielding a 10% increase in power, while reducing the R&D cost by more than 50%.

Agile AI

Unlike the many AI companies that use large models developed elsewhere, or train their own large models, Polaron’s models are relatively small, allowing companies to train their own, bespoke models.

Data that most companies are already collecting for quality control is enough for us to start these optimisation workflows. Dr Steve Kench Polaron

The models can also start work with a modest amount of information about a process. “The level of data collection that most companies are already doing for quality control purposes is enough for us to start doing these optimisation workflows,” says Dr Kench.

In addition to battery material optimisation, Polaron’s methods are applicable to a wide range of materials, from concrete and composites to biomaterials and alloys. It is currently planning pilot studies with early adopters to demonstrate the power of the approach.

AI for the public good

The Manchester Prize is organised by the Department for Science, Innovation and Technology. Every year for the next decade it will reward innovations with the potential to help to transform the lives of people across the UK, and which continue to secure the UK’s place as a global leader in cutting edge innovation.

“With over 50,000 people already employed in the sector and billions expected to be generated for the UK economy over the next few years, the potential of AI innovation to help power our growth is huge,” said Jeremy Hunt, the Chancellor of the Exchequer. “That’s why this funding is one of the best investments we can make.”

The award attracted nearly 300 applications from innovators, academics and entrepreneurs around the UK. “Choosing only ten finalists from such a diverse field of applications was tough; picking a winner will be even harder,” said Dr Hayaatun Sillem, chief executive of the Royal Academy of Engineering and one of the Manchester Prize judges. “I’m looking forward to seeing how the ideas develop in the next few months.”

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ian Mundell

Enterprise