Imperial Materials students reflect on their summer placements

Students from the Department of Materials have shared their experiences from summer placements at Imperial College London and beyond.

Summer placements offer students the opportunity to engage in real-world research, collaborating with researchers or industry in a professional environment for around ten weeks during the summer break.

Imperial offers several programmes to support students with organising placements, including the Undergraduate Research Opportunities Programme (UROP) and the International Research Opportunities Programme (IROP). Students may also choose to arrange their own industrial placement.

In the article below, students from the Department of Materials share their summer placement experiences, what they have learned, and their favourite moments.

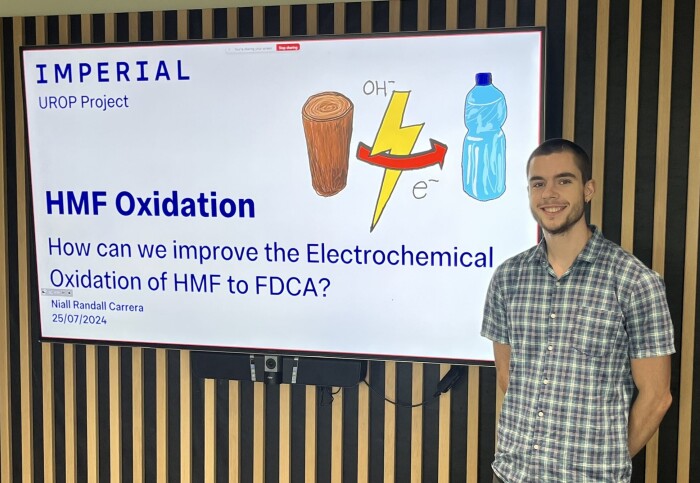

Niall Randall Carrera, UROP at Imperial College London

Niall completed a UROP placement in Professor Ifan Stephens' group in the Department of Materials at Imperial College London.

Niall completed a UROP placement in Professor Ifan Stephens' group in the Department of Materials at Imperial College London.

His project focused on a process called HMF oxidation, which turns a substance made from plants and food waste into a chemical used to create eco-friendly (PEF) plastic. This process uses electricity and produces green hydrogen, a clean fuel.

PEF has better qualities than PET plastic, which is commonly used in water bottles and many other types of packaging. Currently, PET is made from petroleum-based chemicals and requires high temperatures and pressures to produce. Therefore, turning plant-based materials into PEF plastic through an electrochemical transformation is a much more sustainable option.

During A levels, I struggled with electrochemistry, but in my second year at Imperial, I put in extra effort and began to enjoy the subject. This motivated me to explore it further during a summer placement. Niall Randall Carrera

Niall's project involved testing a new molecular catalyst for HMF oxidation, made from carbon, hydrogen, oxygen, and nitrogen instead of expensive and often unethically sourced metals like platinum. Over six weeks, he carried out different electrochemical experiments and then summarised his findings in a presentation to the rest of the group and a paper-style report.

Niall's favourite thing about the project was his independence during the placement, thanks to his supervisor, Dr Zamaan Mukadam. This independence encouraged him to choose which experiments to run and problem-solve when things went wrong.

Niall comments: "Professor Ifan Stephens' group is full of great people who made the placement a fun and social experience.

Niall comments: "Professor Ifan Stephens' group is full of great people who made the placement a fun and social experience.

I'm more motivated now that I have applied what I've learned to real-life scientific research. I have also gained many new skills, both experimental and in scientific writing.

The experience should help with my third—and fourth-year studies."

Simran Khanna, BAE Systems

Simran completed a three-month industrial placement with BAE Systems, working in the Submarines Division. Her role was in Product Safety.

Simran completed a three-month industrial placement with BAE Systems, working in the Submarines Division. Her role was in Product Safety.

Simran began by investigating the method of 'Leak before Break' within pressurised systems onboard submarines. This involved applying much of her fracture mechanics knowledge from university modules and understanding the importance of the structural integrity of the boat. Simran also created safety checklists that all systems could use for Hazard Identification(HAZID) and a report to guide how to use them. Simran also became interested in the work of the Systems Engineering team and the opportunity to learn about lifecycle management.

Simran comments: "It has been great to experience engineering in such a critical setting, where there are many challenges with designing and building such a complex underwater vessel.

I will return to university with a newfound confidence in communication and a better understanding of the applications of my learning."

Alanna Senior, IROP at Massachusetts Institute of Technology (MIT)

Alanna completed an IROP placement at the Massachusetts Institute of Technology (MIT), supervised by Professor Ericmoore Jossou.

Her project involved synthesising, characterising and observing the oxidation of uranium tetraborides alloyed with yttrium, aluminium and chromium.

The project contributed to broader research aimed at developing a new accident-tolerant fuel to replace or serve as a secondary option alongside uranium dioxide in nuclear fission reactors. Developing accident-tolerant fuel (ATF) is important for enhancing the safety and resilience of nuclear reactors, as it can withstand higher temperatures and reduce the risk of radiation release during accidents.

We are hoping to publish a paper and I will be presenting a poster of my summer research at the next Nuclear Materials Conference. Alanna Senior

Alanna comments: "It has been great to work hands-on with radioactive materials for the first time and experience the research culture at MIT.

I feel prepared for my Master's project, which has given me food for thought about whether to do a PhD at MIT.

Outside of the research, it's been a fun summer hanging out with fellow IROP students. Much food and many trips have been involved!"

Miles Asuni, UROP at Imperial College London

Miles completed a UROP placement in Dr Oriol Gavalda Diaz's group in the Department of Materials at Imperial College London.

His project focused on the use of Ceramic Matrix Composites for fusion energy. A composite is a material made by combining two or more different substances, each with its own properties, to create a new material with improved characteristics. Due to their high strength and heat resistance, Ceramic Matrix Composites could be used in fusion reactors for structural components and thermal management.

I really enjoyed the project and the visit to Culham Science Centre with the UKAEA was a great experience. Miles Asuni

During the project, Miles mechanically tested composites under a microscope and used digital image correlation analysis to map the strain. He received training on new equipment, such as a Microtesting Stage and a Scanning Electron Microscope (SEM), and gained experience with research methodology and coding. The placement also involved a visit to the Culham Science Center with the UKAEA.

He comments, "Composite materials are an exciting area of materials. They behave in interesting ways and allow us to leverage more complex properties.

I enjoyed the project, and visiting Culham Science Centre with the UKAEA was a great experience. I had the chance to talk to many people about fusion energy, a topic I'm very interested in."

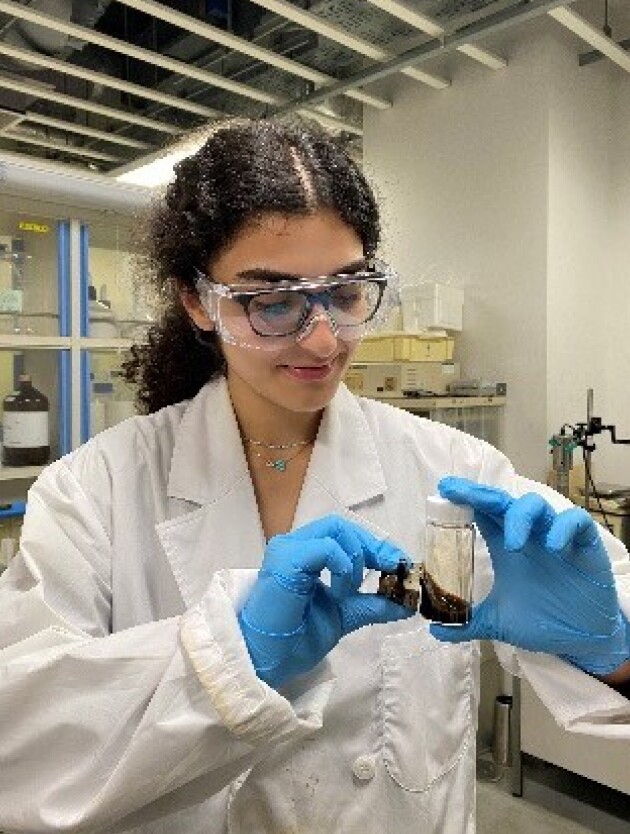

Ayla Ipakchi, Institute of Science Tokyo

Ayla completed an IROP placement at the Institute of Science Tokyo under the supervision of Professor Yoshitaka Kitamoto.

This experience allowed me to apply the knowledge I've gained from lectures and projects." Ayla Ipakchi

Ayla comments: "This experience allowed me to apply the knowledge I've gained from lectures and projects while also deepening my understanding, particularly in nanotechnology—a field I’m eager to explore further after graduation.

It has been an eye-opening opportunity. The skills I’ve developed will prove invaluable for my final year project and future career.

I loved immersing myself in Japan's energetic working environment and experiencing its rich, beautiful culture.."

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Kayleigh Brewer

Department of Materials