Paper sends a signal in PulpaTronics’ alternative to metal-and-silicon RFID tags

by Ian Mundell

An Imperial startup has raised £430,000 to begin testing its low-cost, recyclable radio-frequency ID tags with retailers.

The tags attached to new clothing seem innocuous, but each one is essentially an electronic device. A microchip embedded in the tag stores information about the item, while a metal antenna allows the information to be accessed through a radio frequency reader. Together they make it possible for retailers to track inventory, operate self-checkout systems, and reduce theft.

But the multi-component tags are expensive to make and the combination of paper, plastic, silicon and metal makes them a nightmare to recycle. Plus, they add up: in the global fashion industry alone, more than 12 billion radio-frequency identification (RFID) tags are produced for single use each year, most ending up in landfill.

PulpaTronics, a startup company with its roots at Imperial, has a solution: all-paper RFID tags that are cheaper to make and can be dropped in a regular recycling bin once they have served their purpose. After over a year of R&D, the company has just raised £430,000 in pre-seed funding to accelerate product development and launch its first pilot studies with leading retail and packaging companies.

If a major retailer like Zara switched to our tags, we could already help them save 2% of their entire year’s greenhouse gas emissions. Chloe So PulpaTronics

“This investment not only kickstarts the growth of our vision but also empowers us to accelerate our R&D for commercialisation, so that we can do our part to make an impactful contribution towards climate change,” said Chloe So, co-founder and chief executive of PulpaTronics. This contribution could be substantial. “If a major retailer like Zara switched to our tags, we could already help them save 2% of their entire year’s greenhouse gas emissions,” she added.

The funding round was led by Sustainable Ventures, with contributions from NextSTEP, the NextEnergy Group’s venture fund; the Royal College of Art’s Design and Innovation S/EIS fund; molecules.vc; and the Cranfield Seed Fund. These funds were joined by angel investors Pierre Paslier (co-chief executive of Imperial startup Notpla), Adam Taylor, Thomas Plein and Suzannah Steele.

Making carbon work

The PulpaTronics approach dramatically reduces the components needed to make an RFID tag, cutting costs and simplifying recycling. In place of the metal antenna, the company uses a laser to convert carbon in the paper substrate into a conductive material, essentially etching an antenna onto the paper. The microchip can then be replaced by encoding data in the shape of the antenna, in much the same way that a QR code holds information in its pattern.

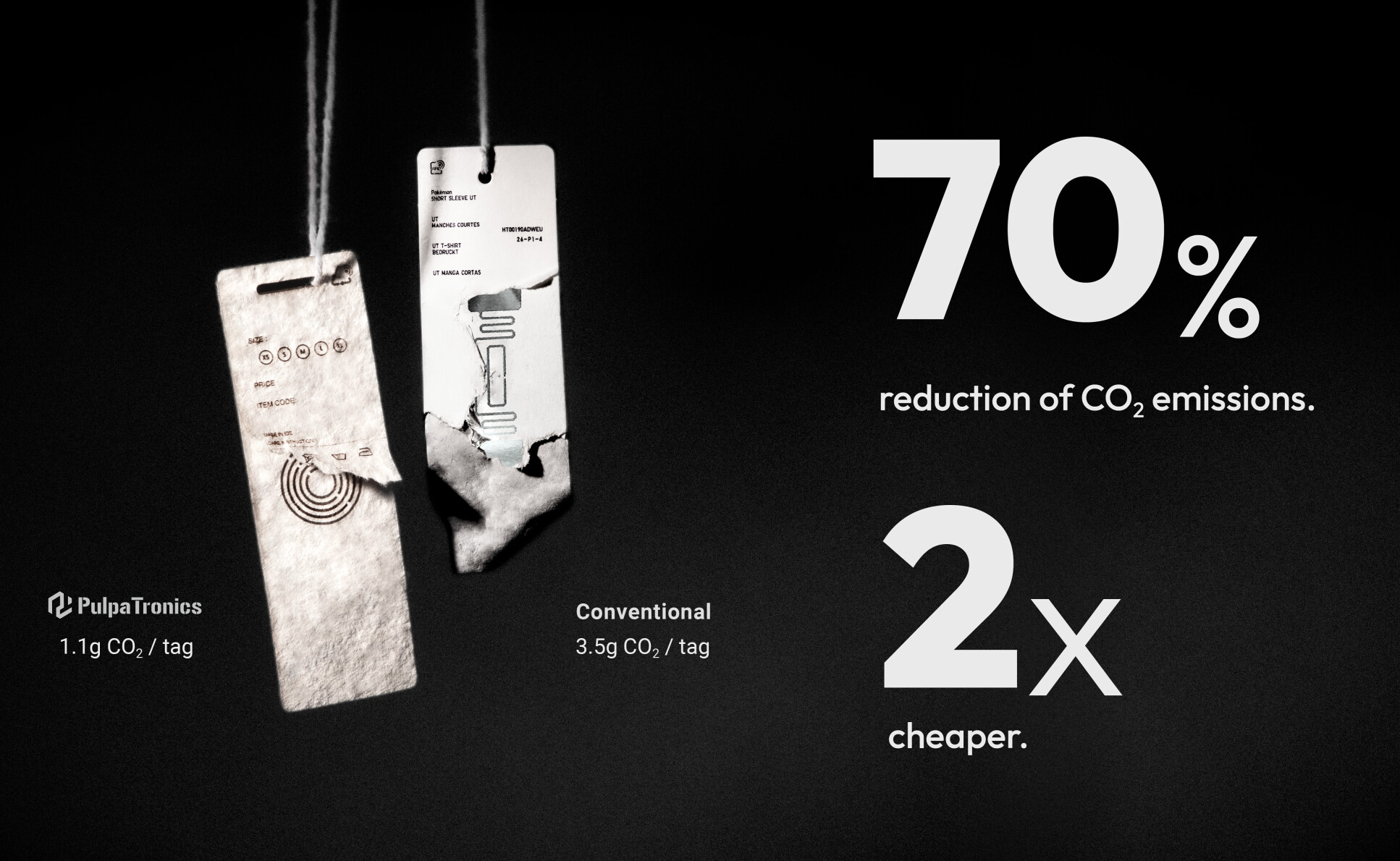

The result is a paper tag that can be recycled along with other paper and card. Costs are cut in half, and there is a 70% reduction in carbon footprint compared to a traditional RFID tag.

“We check the sustainability box, and we check the price-point box, and I think that’s why investors were so excited about this product and willing to give us their money,” said Ms So.

The idea came to company co-founders Chloe So and Barna Soma Biro during a group project for the Master’s programme in Innovation Design Engineering, run jointly by the Dyson School of Design Engineering at Imperial and the Royal College of Art. Together with two colleagues from the course they then entered the 2023 Venture Catalyst Challenge, Imperial’s flagship entrepreneurial competition, going on to win the Creative and Consumer track prize.

“The VCC competition kept us thinking about the idea while we were also busy completing our studies,” Ms So recalled. “It helped us hone our pitch and gave us a lot of resources on how to build a company from the ground up.”

Meanwhile, they were able to use resources at Imperial to start optimising a paper substrate for use with lasers, and to test their first tags in the Department of Electrical and Electronic Engineering’s near-field communication lab.

After the VCC, PulpaTronics went on to participate in The Greenhouse, Undaunted’s climate accelerator. “That gave us 12 months and £20,000 to try to make our idea work,” Ms So said. “Together, these two initial programmes really pushed us to execute our vision.”

Ready to pilot

At the same time, PulpaTronics ventured out from Imperial to join the Future Frontiers Fund programme at Cranfield University. This provided further funding for the team to gain a deeper understanding of chipless RFID technology, while testing the robustness, durability and performance of its RFID tags under various conditions.

The final phase of our first round of R&D is all about substrate optimisation, looking at off-the-shelf materials and different paper pulps to see what higher levels of connectivity we can achieve. Barna Soma Biro PulpaTronics

“We are in the last phase of our first round of R&D, which is all about substrate optimisation, looking at off-the-shelf materials and different paper pulps to see what higher levels of connectivity we can achieve,” said Barna Soma Biro, PulpaTronics’ chief technology officer.

The company is also completing an Innovate UK Net Zero Living grant, which has enabled it to build its first prototype chipless tag reader and test various aspects of the technology with Petit Pli, another Imperial startup, which makes children’s clothes designed to keep pace with growing bodies.

Meanwhile, the company has picked up numerous prizes for its technology, including from Dezeen, IDEAs, and IET Excellence and Innovation. This exposure has generated high levels of interest from retail and packaging companies. “A lot of our commercial pilots lined up for 2025 have come through that channel, so we haven’t had to do any marketing or make too many cold calls,” Ms So said.

These pilot trials will involve hybrid tags with carbon-based antennas that function similarly to conventional UHF RFID tags. “That allows us to work with existing store infrastructure and have a more seamless integration when working with different brands,” said Ms So. “And that will help us get to the market quicker.”

The pre-seed investment will help build an automated production line feeding tags to these pilot studies. The money has also helped the team grow, taking in additional expertise in radio-frequency technology, lasers and paper substrate optimisation.

Next, PulpaTronics is looking to broaden its network. “We would love to get connected with people who would be interested in advising us, or serving on our first board of directors,” Ms So said.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ian Mundell

Enterprise