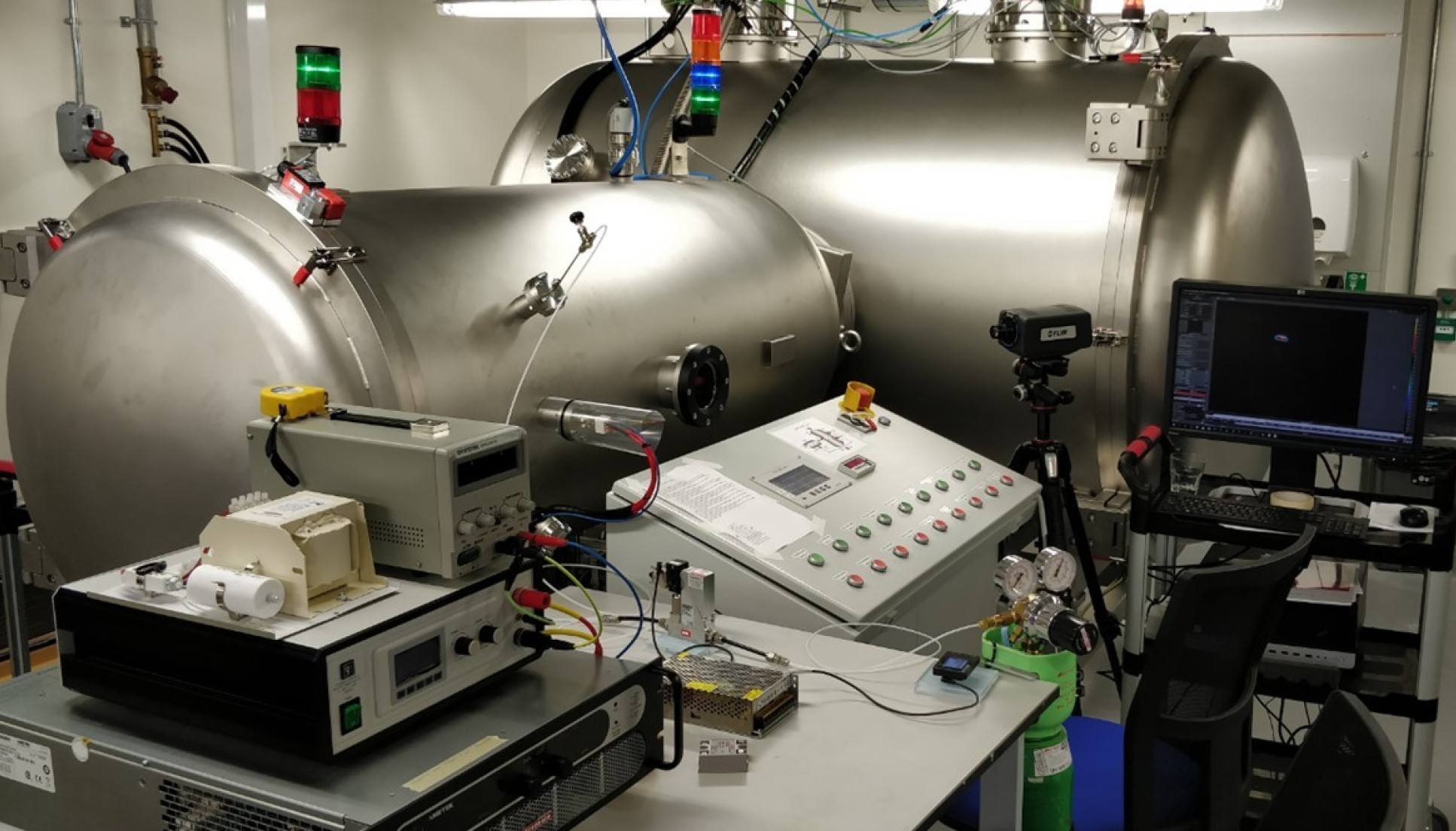

Boltzmann Vacuum Chamber

The Boltzmann chamber, commissioned in July 2018, uses a series of vacuum pumps to achieve background pressures representative of the low earth orbit environment. Its primary use is for the experimental characterization of plasma thrusters for spacecraft propulsion applications (also referred to as Electric Propulsion).

Boltzmann is composed of a main and load lock (hatch) chamber separated by a gate valve, as seen in the above picture. The main chamber is 2 m in length and 1.5 m in diameter and the load-lock (hatch) chamber is 1.5 m in length and 0.75 m in diameter.

The main chamber is equipped with a three-stage pumping system composed of a Leybold LV 80C roughing pump, two Pfeiffer ATH 2303 M turbomolecular pumps each with a 2150 l/s pumping speed (N2), and a Leybold COOLPOWER CP140T cryopanel connected to a COOLPAK 6000H compressor unit. The load lock (hatch) chamber is equipped with a two-stage pumping system composed of a Leybold LV 80C roughing pump and a Pfeiffer HiPace 700 M turbomolecular pump with a 685 l/s pumping speed (N2).

Maxwell Vacuum Chamber

The Maxwell chamber functions in a similar way to Boltzmann. Composed of a single cylindrical chamber roughly 0.5 m in diameter and 0.5 m in length, it relies on a two-stage pumping system to achieve background pressure levels conducive to Electric Propulsion (EP) testing. In this case, a Trivac D16 A rotary vane pump is used in combination with a CTI Cryogenics Cryo-Torr 8 cryopump.

The Maxwell chamber functions in a similar way to Boltzmann. Composed of a single cylindrical chamber roughly 0.5 m in diameter and 0.5 m in length, it relies on a two-stage pumping system to achieve background pressure levels conducive to Electric Propulsion (EP) testing. In this case, a Trivac D16 A rotary vane pump is used in combination with a CTI Cryogenics Cryo-Torr 8 cryopump.

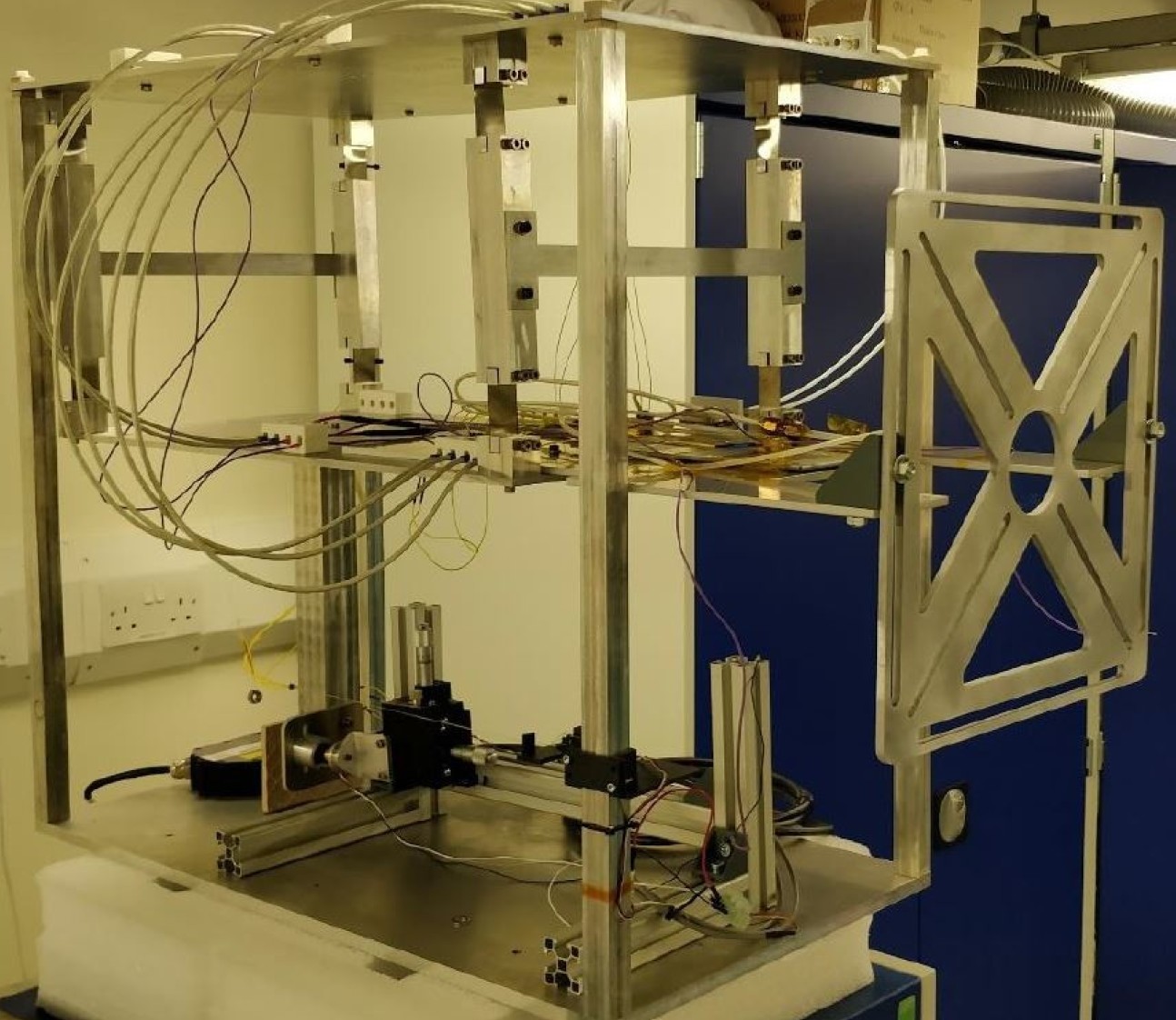

IPPL Thrust Balance

The IPPL thrust balance is a hanging pendulum style balance for performing direct thrust measurements of electric propulsion (EP) devices. Developed under a contract with the European Space Agency (ref. 5001026101), it measures thrust in the 1-1000 mN range with a precision of roughly 0.2 mN. Thermal stability is ensured by a closed loop-self compensating heating system, while traceability and stability of the calibration are ensured using two separate sub-systems: a Voice Coil Actuator (VCA) and a servomotor pulley system.

The central platform of the balance connected to a rigid support through an array of thin steel flexures, which effectively create a free hanging pendulum. A test article, such as a thruster and cathode, is mounted on the swinging platform using the interface plate. The thrust produced by the test article causes the central platform to move along the axis of thrust as the flexures bend. The relative displacement between the base and the central platform of the balance is measured with a laser triangulation sensor with sub-micrometer precision.

The balance sensitivity factor, which allows researchers to translate the displacement measured by the laser triangulation sensor into a thrust value, is determined using a VCA-based cross-calibration sub-system. The calibration forces produced by the VCA are first measured at a range of currents using a NIST traceable micro-balance. During this process, current is supplied using a high precision source meter. With the chamber vented, the VCA is then positioned at the base of the balance and made to provide the series of repeated non-contact calibration forces. The resulting displacement is measured, and the balance sensitivity factor thus calculated. A second calibration sub-system is used in-situ to monitor the stability of the balance sensitivity while in vacuum. This is achieved using a remotely commanded servo-motor fixed to the balance rigid support and connected through a guide hole to a test mass which is itself secured to the central platform. By rotating the servo arm, and so by changing the angle of the thread between the test mass and the central platform, a repeatable force along the thrust axis is created.

Further information on the IPPL thrust balance design and operation can be found here.

Plasma Diagnostics

The IPPL has a variety of diagnostic tools for plasma measurements and characterization available. These include Langmuir probes and an ExB probe. Furthermore, the lab also has a FLIR thermal imaging camera and a residual gas analyser available.