Resource sharing for better research

In this period of unprecedented environmental change, the need to take urgent, meaningful climate action is undeniable. The UK Research and Innovation sector, leaders in informing climate science, is well placed to lead the way in making R&I itself environmentally sustainable. As a world-leading STEMB university, Imperial aims to be at the forefront of this change. We are committed to creating sustainable environments for learning, teaching, researching and working and becoming a net-zero institution by 2040, and we were one of the first signatories of the Concordat for the Environmental Sustainability of Research and Innovation Practice. Our sustainability strategy (2021-2026) underpins the university-wide work we are doing on this, with much of it being complemented by action taken at faculty and department level.

The Department of Bioengineering is one of our departments pioneering sustainable laboratory practices at Imperial. The department’s sustainability committee, led by Dr Claire Stanley, oversees and coordinates this work. The committee meets monthly to discuss actions to improve sustainability in the department at various levels.

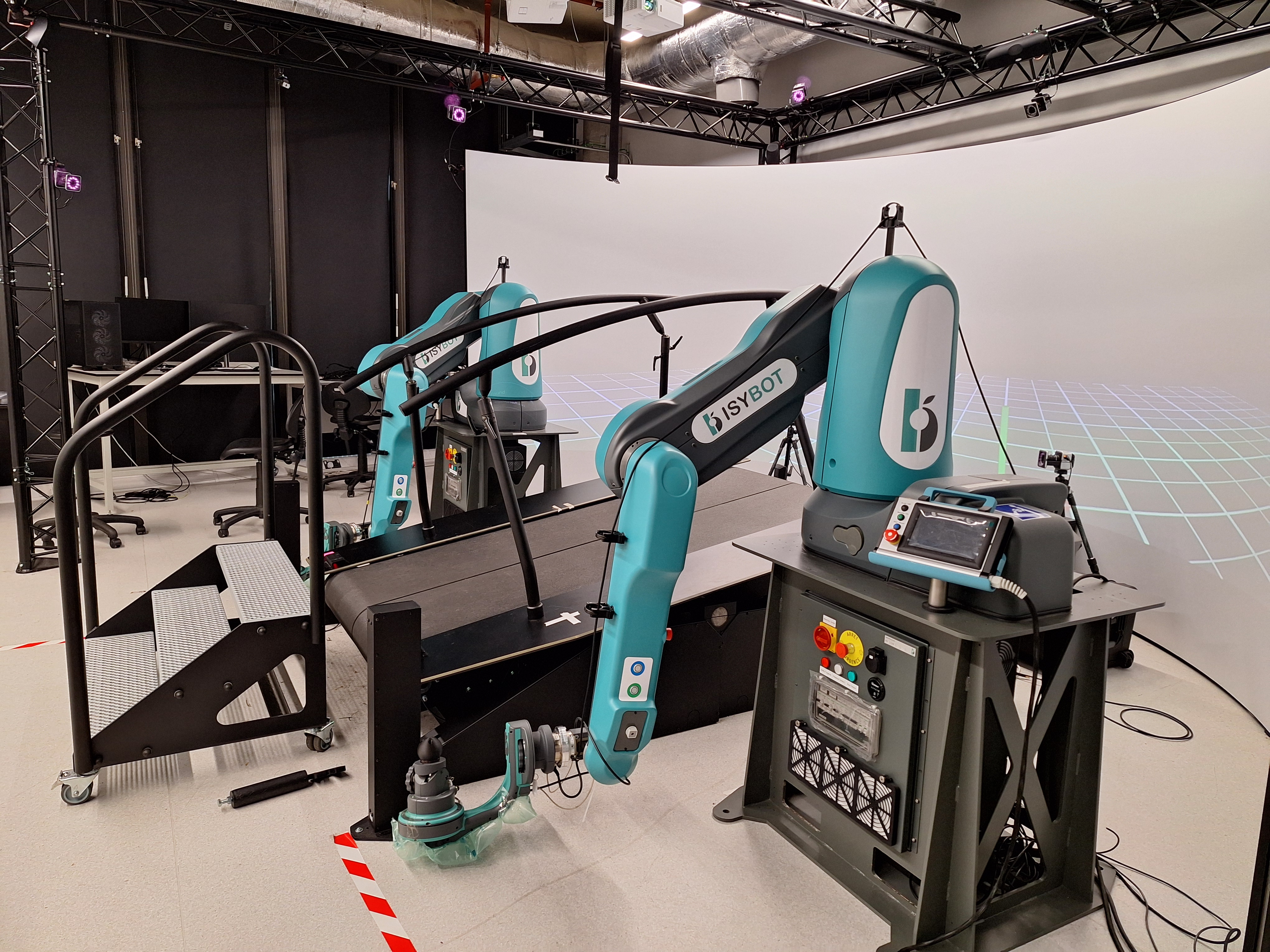

A key area of focus has been around equipment, facility, and consumable sharing, led by Dr Miguel Hermida Ayala, Deputy Technical Operations Manager. At the Department of Bioengineering, most large pieces of equipment are set up as shared equipment, available for everyone at Imperial to use. This is possible because all equipment is registered on PPMS (the facility and equipment booking and management system) and TRAC-listed, meaning that usage of equipment (and facilities) can be directly charged monthly, with no administrative burden on facility managers or users. Equipment requests on grant applications are reviewed by the department to assess need, considering current equipment availability across Imperial facilities. As a result of all these measures, usage of shared equipment managed by the department has been increasing sharply every year: in 2022, the total number of hours booked on the system was just under 14,500; this increased to over 41,000 in 2023 and nearly 100,000 in 2024.

An additional benefit of the centrally managed equipment is the development of relationships with local industry partners by allowing them to rent equipment. “Companies are attracted by our excellent facilities, close hospital links, and reputation for world-class research, as well as the support provided by our facility managers and technicians,” details Dr Florent Seichepine, Engineering Core Facilities Manager.

The department has also worked to promote sharing of facilities, particularly in the White City campus. “If we take the example of a tissue culture room, this would typically be ‘assigned to’ a particular Principal Investigator or research group. Instead, we make them available for anyone in the department to use and divide them according to the type of work being undertaken. This allows us to attribute them different levels of access based on training needed, a process which is overseen by our team of facility managers,” explains Florent. They also have shared molecular biology labs, which can be rented out by the hour – particularly useful in an engineering department, where most researchers may only need sporadic access to those facilities.

To share consumables across the different research groups, they use labcup, a laboratory inventory management platform, and some reagents that are widely used across the department, such as cell culture media, are bought in bulk to reduce cost and waste.

Underpinning much of this work has been the Department’s drive to increase participation in LEAF and My Green Lab, environmental accreditation schemes that give participating laboratories sustainable actions to carry out, including across waste, energy, and procurement. The Department is working towards having all their labs accredited with LEAF by summer 2025.

In the future, they hope to create better routes for communication with other facility managers across Imperial, to facilitate collaboration on sustainable initiatives, mutual learning and sharing of best practice. Sustainable research practice, where resources are shared and facilities and equipment are centrally managed by dedicated teams, contributes to a more positive research environment and, thus, better research.

We encourage any researcher interested in trying biosciences or engineering equipment or techniques to get in touch. The Department of Bioengineering offers free training and support, with hourly access to over 100 pieces of high-end equipment, led by a diverse and dedicated Technical Team.

Dr Miguel Hermida Ayala, Deputy Technical Operations Manager