Heterogeneous materials

- Porous and granular materials studies with a shock tube

- High rates compression of cells for blast injury studies

- Cellular biomechanics of blast

- Thuy-Tien N Nguyen (PhD student)

- Theresa Davey (PhD student)

- William Proud

Porous and granular materials have been used as protective covers and filters thanks to their shock attenuation properties. In this project, the percolation of gas and attenuation of blast waves through granular beds and perforated sheets were investigated using a shock tube. This study had two purposes, firstly to understand the effect of such materials on blast waves and secondly to allow us to adapt the pressure tube to produce a wide range of pressure pulses with control of height, duration and wave shape.

To place these studies in context, the blast waves produced by the shock tube corresponded to the output seen at 9–12.6 m from 20 kg TNT. At the low pressure end of this range pressures used can cause rupture and tearing of eardrum in 50% exposed population, while 1% ending in permanent hearing loss due to severe ruptures of the ear membrane.

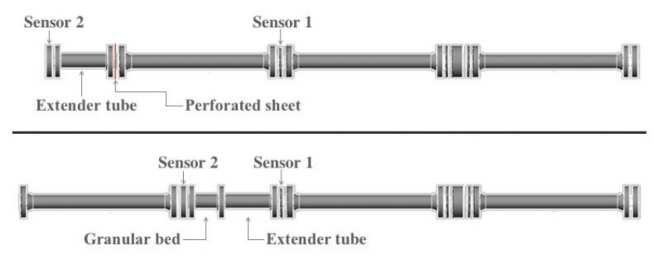

In the system 0.7 mm thick galvanised perforated steel sheets of different porosity were used, with 22%, 46%, 68%, and 79% of the plate surface being the holes. In addition, granular materials studied were samples of soda lime glass monospheres with diameters of 1.5, 2.0, 2.5, 3.5, 4.0, and 5.0 mm. These materials were used to form granular beds of 147, 123, 72, and 47 mm length. The beds were sealed at both ends with 46% perforated sheets. These perforated sheets and granular beds were inserted into the shock tube system as shown in figure 22.

Publication: 1. T-T N Nguyen, T Davey, WG Proud Percolation of gas and attenuation of shock waves through granular beds and perforated sheets In proc. New Trends in Research of Energetic Materials, Czech Republic, 2014

- David R Sory (PhD student)

- Anabela Cepa-Areias (PhD student)

- William Proud

- Darryl Overby

- Sara Rankin

This research takes forward ISP PhD graduate Dr Chiara Bo’s research into using Split Hopkinson Pressure Bars (SHPB) to load biological samples. Experiments are underway to study the effects of load and strain rate on cells immobilised in a three dimensional gel culture. In the theme of Blast Force Protection a full range of testing facilities in dynamic compression experiments has been developed for the examination of different aspects of blast waves. The facilities include a drop-weight impact tower, a SHPB and a 32 mm bore light gas gun. One of the main assets of the equipment lies in the capacity to load biological samples over a large and continuous range of strain rates (from the intermediate up to the very high strain rates) producing stresses relevant to blast processes.

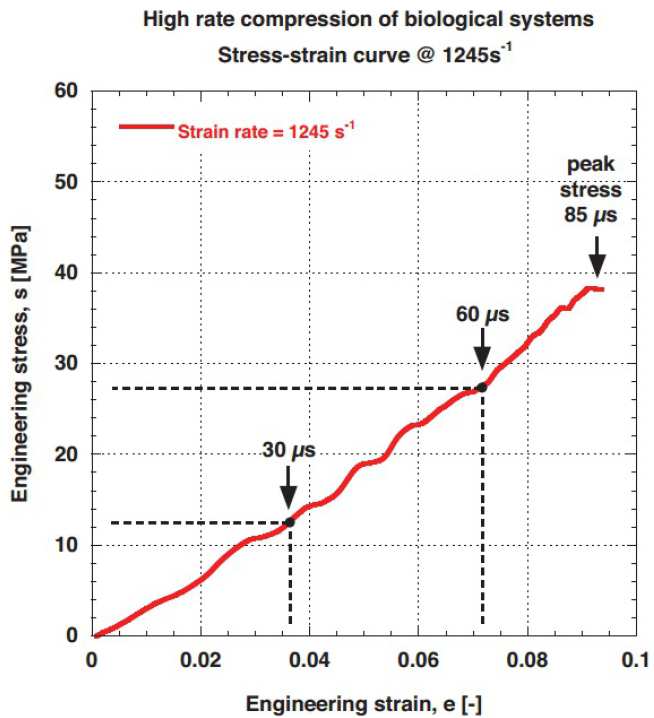

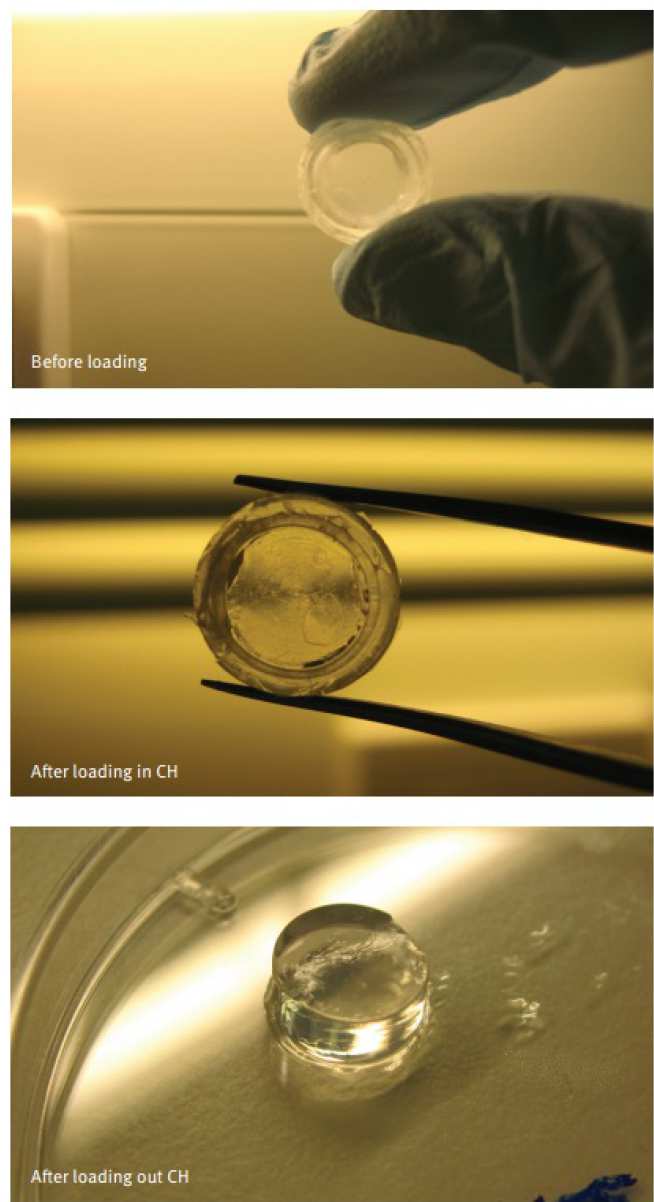

Initial experiments have been performed on a newly-designed biological load cell dynamically loaded in the SHPB. The biological load cell consists of cylindrical 3D-gel cell culture hermetically sealed in a polydimethylsiloxane silicone sample holder. An annotated photograph of the sample holder is shown in figure 23. Besides the benefits of fulfilling both the biological requirement of sterility and maximize transmission of the input stress to the gel sample, the polydimethylsiloxane silicone was chosen to facilitate gel recovery and post-pressurisation analysis such as cell survivability mapping and cell proliferation studies. Figure 24 shows three images taken during the compression of the new sample holder on the SHPB. The stress and strain levels experienced by the biological system in respect of the image time are presented in figure 25.

Along with the SHPB, a gas gun facility and a miniature drop-weight has been developed and brought into a calibration process in order to routinely allow material properties investigations of soft matter, and more specifically involve key experiments aiming to study the repercussions of high stress short duration pulses, and the effects of impulse delivered on biological systems.

Figure 23: Loading apparatus. A jacket surrounds the sample holder to ensure uniaxial strain is achieved.

Figure 24: High speed photography of the prototype sample cell during SHPB loading.

Figure 25: Stress strain curve of the biological systems. The arrows indicate the stress and strain levels experienced by the sample in respect of the images shown in figure 24.

- Anabela Areias (PhD student)

- Darryl Overby

- Jane Saffell

- David Sory (PhD student)

- William Proud

Blast injuries are the most common consequence of modern warfare in military personnel and civilians,1 affecting the biological functions of the body. Primary blast injuries are a result of the body being exposed to a discontinuous change in pressure produced by the blast wave.2 Living cells sense and respond to mechanical stimuli associated with the conditions of blast wave by changing their structural and functional attributes. In future work, the aim is to identify these biological changes within living cells by creating a model, which will allow us to mimic part of the real event. The intention is to use a Split Hopkinson Pressure Bar (SHPB) to produce high stress waves combined with Tissue Engineering techniques to produce a natural 3D cell environment. In this way, the current research is being focused on the design and development of a cell-seeded 3D hydrogel and (B) its holder that would interface with the SHPB allowing in vitro overpressure experiments with reproducible stress transmission.

Once the system optimisation is completed, the in vitro system will be used to induce cellular injury or immediate cell death. In a first stage, the target is establishing a connection between cell death and mechanical stress levels. Then, the examination of the cellular viability, cytoskeletal architecture, cell adhesions and DNA will be performed in order to understand how these changes within the cell may contribute to later pathology and morbidity in survivors of primary blast injury.

Publications: 1. SD Masouros, KA Brown, J Clasper, WG Proud et al. Briefing: Blast effects on biological systems Proceedings of the Institution of Civil Engineers: Engineering and Computational Mechanics, 166, 113–118, (2013) 2. SJ Wolf, VS Bebarta, CJ Bonnett, PT Pons, SV Cantrill Blast injuries Lancet, 374 (9687): 405–15 (2009)

Figure 28: Hydrogel inside its correspondent holder before (A) and after (B) loading. Hydrogel outside its holder after loading (C).