Spinning sustainable carbon fibres for the energy transition

More sustainable carbon fibre? Professor Milo Shaffer, Agi Brandt-Talbot (Imperial) and Pascale Launois (CNRS) project.

Spinning sustainable carbon fibres for the energy transition

A CNRS-Imperial joint PhD project conducted by:

Prof Milo Shaffer – Imperial PI

Dr Agi Brandt-Talbot – Imperial PI

Prof Pascale Launois – CNRS PI

Enny Tran – Imperial PhD student

Lucie Dieval – PhD student CNRS

Take a high end bike that is enviably light, so light in fact that you can lift it with one hand. The chances are it is made from carbon fibre, a material which dates back to the 1870s when it was first used for filament lightbulbs. Making new materials or improving on the old ones is a slow process. It requires a diverse set of skills to first synthesise and then test its capabilities. A case in point: carbon fibre’s incredible strength for its weight was only realised a full hundred years after its synthesis. Early experiments subjected natural fibres like cotton and silk to high temperatures, transforming their atomic structure to a more carbon rich, crystalline one, in a processes known as graphitisation. But today, the building blocks come from fossil fuels. In this project, natural fibres once again take centre stage as researchers from the CNRS and Imperial College London aim to make an old material in new, more sustainable ways.

To discover more about the project listen to the International Relations Office podcast "Voices of International Collaborations".

Voices of International Collaborations, Episode 1: Sustainable Carbon Fibers (Imperial/CNRS)

Discover more about the project

Open to read the transcript

INTRO

What are the possibilities when scientists collaborate across borders?

Enable great ideas to develop, Make new materials, revolutionise cancer treatment, and unlock the secrets of the physical forces that shape our world.

These projects highlight some of the incredible collaborative science made possible by the International Research Centre, a joint venture between Imperial College London and the Centre National de Recherche Scientifique or CRNS in France.

NARRATOR

Take a high-end bike that is enviably light, so light in fact that you can lift it with one hand. The chances are it is made from carbon fibre, a material which dates back to the 1870s when it was first used for filament lightbulbs. Making new materials or improving on the old ones is a slow process. It requires a diverse set of skills to first synthesise and then test its capabilities. A case in point: carbon fibre’s incredible strength for its weight was only realised a full hundred years after its synthesis. Early experiments subjected natural fibres like cotton and silk to high temperatures, transforming their atomic structure to a more carbon-rich, crystalline one, in a process known as graphitisation. But today, the building blocks come from fossil fuels. In this project, natural fibres once again take centre stage as researchers from the CNRS and Imperial College London aim to make an old material in new, more sustainable ways.

MILO

Carbon fibres are lightweight structural materials. They are fantastic. Uh, we use them anywhere. We need high-performance, strong, stiff materials, for example, in aircraft. And they generally improve fuel economy and reduce weight in their use. But their production at the moment is quite energy intensive and is derived from petrochemical precursors.

I'm Milo Shaffer. I'm a professor of materials chemistry.

NARRATOR

Professor Shaffer from Imperial College is one of the principal investigators on this project. His research focuses on nano-materials, like carbon fibres, which could help shift our society to a carbon-neutral one.

MILO

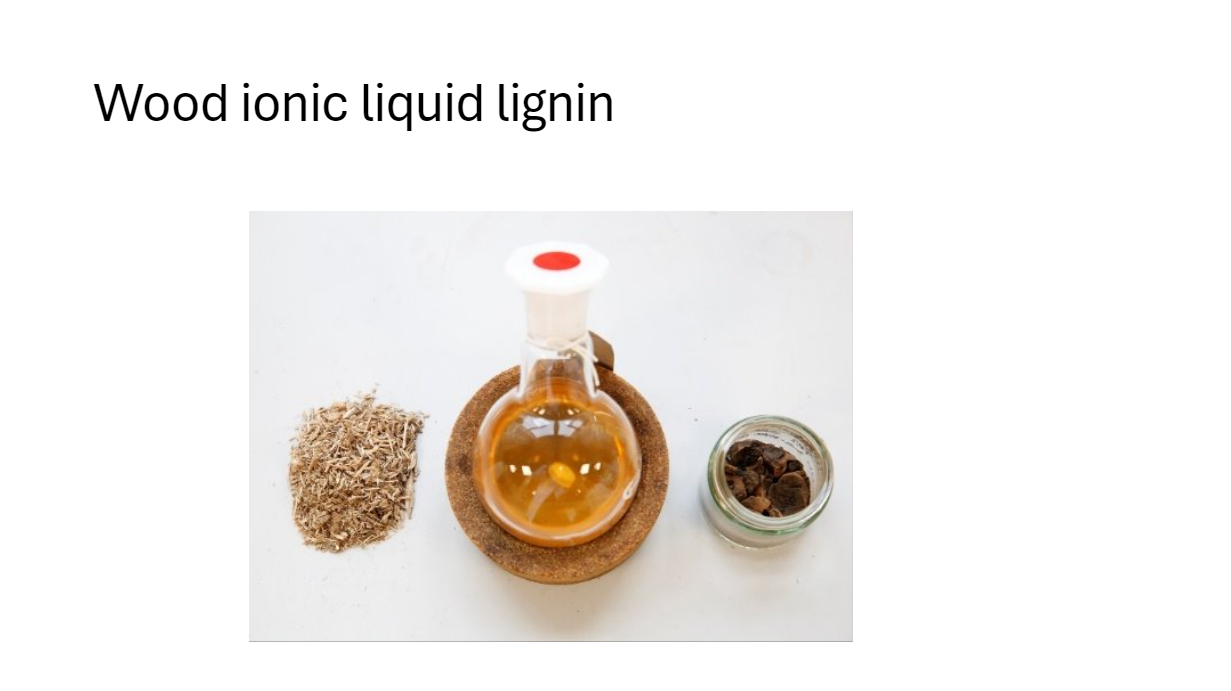

So this project is about developing a different way to make carbon fibre from renewable resources, specifically from lignin. Lignin is a component of wood. So what we're really talking about is taking biomass, in other words, trees or grasses. They could be waste biomass, could be like sawdust or chippings, and then converting that into, you know, really high-performance material.

NARRATOR

Lignin is the second most abundant polymer on earth after cellulose and is responsible for giving trees their structure and rigidity. But before it can be converted, lignin must first be separated from other plant materials. Lecturer in Chemistry at Imperial and Joint principal investigator Prof Agi Brand Talbot is an expert in lignin Chemistry and characterising fibres to determine their physical, thermal, and mechanical properties.

AGI

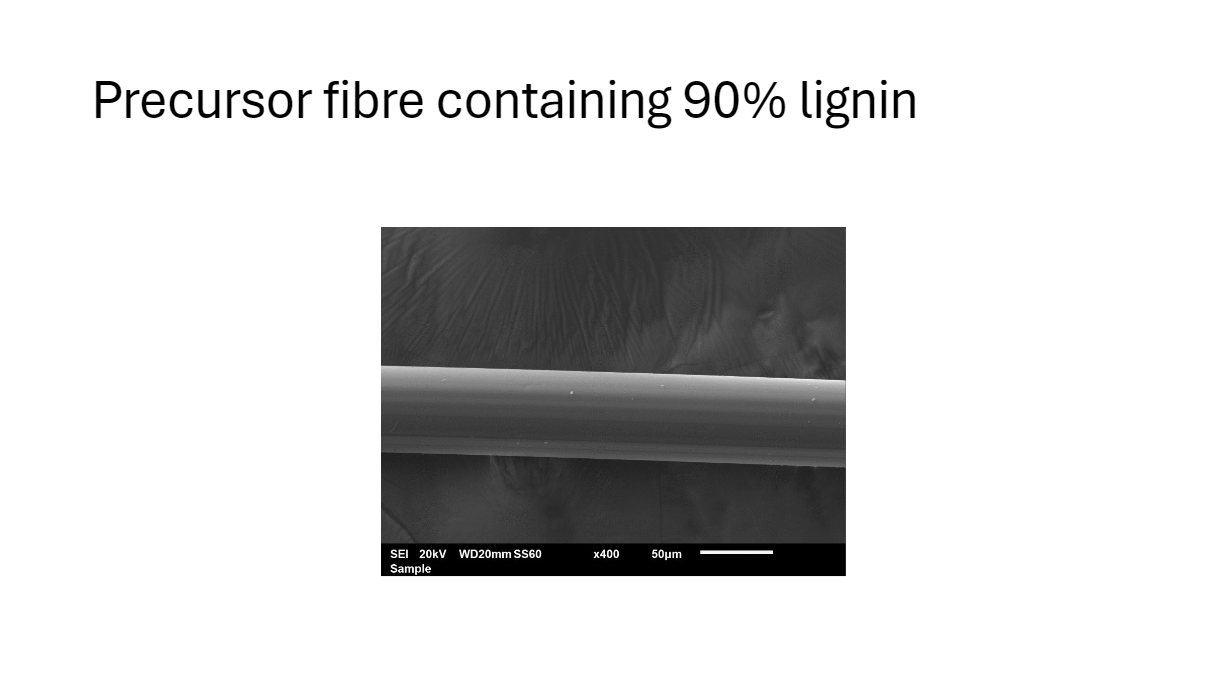

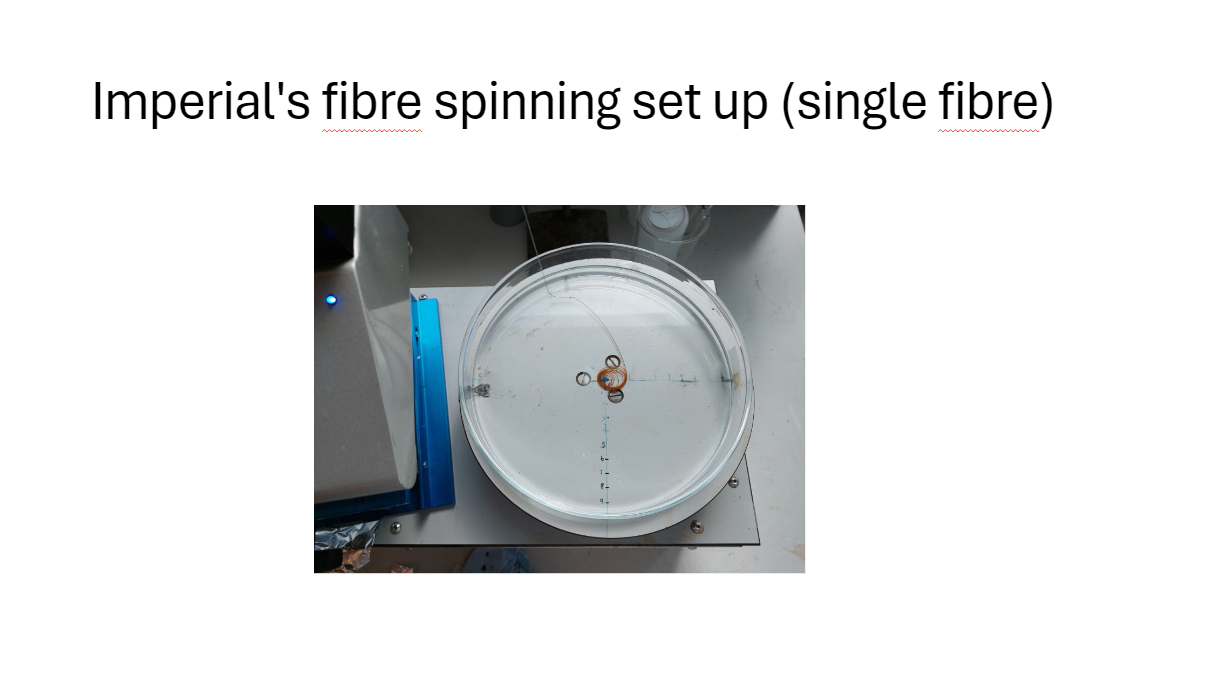

I'm a lecturer in the Department of Chemistry here at Imperial College. I'm bringing in, um, the, um, experience in sort of extracting and characterising, um, the lignin, sort of, knowing where it's, you know, what sort of liquid it's soluble in and which it's not soluble in, so we can make those fibres. Another goal of our project is to, so we don't, we want to make the materials more sustainable and lower cost as well. And lignin has that promise that you can, the materials can be, the raw materials are cheaper and then the conversion is, is our conversion method is, is lower cost as well. We have a way of extracting the lignin. And then we've now also developed, sort of, over the last two, three years, a method to bring it into a fibre form and then transform it into carbon fibres.

NARRATOR

But this is easier said than done and requires instrumentation and expertise that traverses borders. Back to Professor Shaffer:

MILO

The challenge is how to graphitise those lignin fibres, which are normally considered to be rather difficult. And to help us, we're working together with CNRS in Paris, because they can study the structure of the carbon as it converts at high temperature, using, uh, x-ray scattering techniques.

Uh, there's not an obvious one in the UK, for example. So it makes sense to, uh, collaborate with, uh, different groups, um, and institutions where there is an established capability there. So we're trying to do something for the world if you like. It would make sense to find the best places in the world to accelerate the process.

So they have a specialist focus on scattering, where you can get very intense X-rays, which is good if you want to look at the sample as it changes in real time. What we're hoping is that we'll, you know, add a really complementary facet. So, we're very much experimental, doing the materials development, but with, you know, The skills in, in CNRS, we should be able to understand much more fundamentally what's going on. So that should accelerate the progress a lot.

NARRATOR

CNRS Research Director, Professor Pascale Renoir is the final principal investigator working on this project, bringing analytical techniques and a different perspective to the project. By firing X-rays at the carbon fibres made by Imperial College and analysing the patterns formed when they pass through the material, Prof Renoir can determine their crystal structure and other useful properties. This helps the team compare the similarities and differences between their lignin derived fibres and current ones in use for manufacturing.

PASCALE

I'm Pascale Launoy, I'm a physicist working at the Laboratory of Solid State Physics. I am a specialist in x-ray scattering and analysis of x-ray scattering diagrams, which give information on order, disorder, structure, orientation of objects, and so on. This collaboration has been very complementary….

The ultimate goal is to produce marketable blue-derived carbon fibres. But even if we don't succeed in doing it, we will make progress in this direction and understand the carbonization and graphitization process of a lignin-based fibre. Also, if we are able to understand the graphitization process of lignin, it can be useful for the production of batteries and supercapacitors.

Working at the cutting edge of material science to achieve that goal are PhD students, Enny and Lucie, who have joint supervision from all 3 PIs. Although each has their specific area of focus, they collaborate closely

They do not only do they assist with the project, but they also gain experience working in another country

ENNY

I'm Eni, a first-year PhD student in materials at Imperial College London. Lucy's working on, um, like x-ray scattering of these carbon fibres, but there are a lot of other techniques that we can use, so, um, such as transmission electron microscopy, and we can also, uh, use focus ion beams to get, like, specific sections of these fibres to analyze in more detail. I'm excited to go and visit them and see how their research group works. They'll have different areas of expertise because they have an x-ray synchrotron which has massive capabilities, so I'll be able to learn more. I'm excited about this collaboration, um, yeah, I haven't, um, collaborated with people internationally, so, uh, and, like, um, learning more about materials characterization is exciting.

LUCIE

I'm Lucie, I just started my PhD under the supervision of Pascal Launois. With Ennye, my fellow PhD student at Imperial College, we exchange ideas and discuss our results approximately once a month. During our last visit, Enny, Milo, and Agi demonstrated the process of making and characterizing lignin-based fibre. This hands-on experience provided me with a deeper understanding of the process and the challenges they face while making those fibres. We also brainstormed on new experimental ideas that we could make and presented the results we had so far.

NARRATOR

So this cohort of researchers has already started to make carbon fibres derived from lignin on a small scale. But once we have our functional carbon fibres, what can be done with them? Well, that depends on what they are needed for. By combining carbon fibres with other materials, it is possible to make composites that are customised to specific uses. Carbon fibres are quite brittle by themselves, so are often suspended in a more flexible substance called a matrix.

MILO

There's a lot of work in the world now considering how to make bio-derived or sustainable matrices for composites. So, because The most common systems are epoxy based, which are petrochemical, but a lot of interest in, uh, making them out of, uh, renewable resources as well.

So in principle, you could then combine a renewable matrix with our renewable lignin fiber and have an all-renewable composite.

AGI

The carbon fibre composites are also very interested, interesting in wind turbines, so they can make the blades lighter and then higher performing.

So we get more energy, um, from a single wind turbine. Um, yeah, those sort of, those would be our target markets. So large scale where we can really have an, have an impact on, on, you know, the sustainable, sustainability of our energy use and fuel efficiency.

MILO

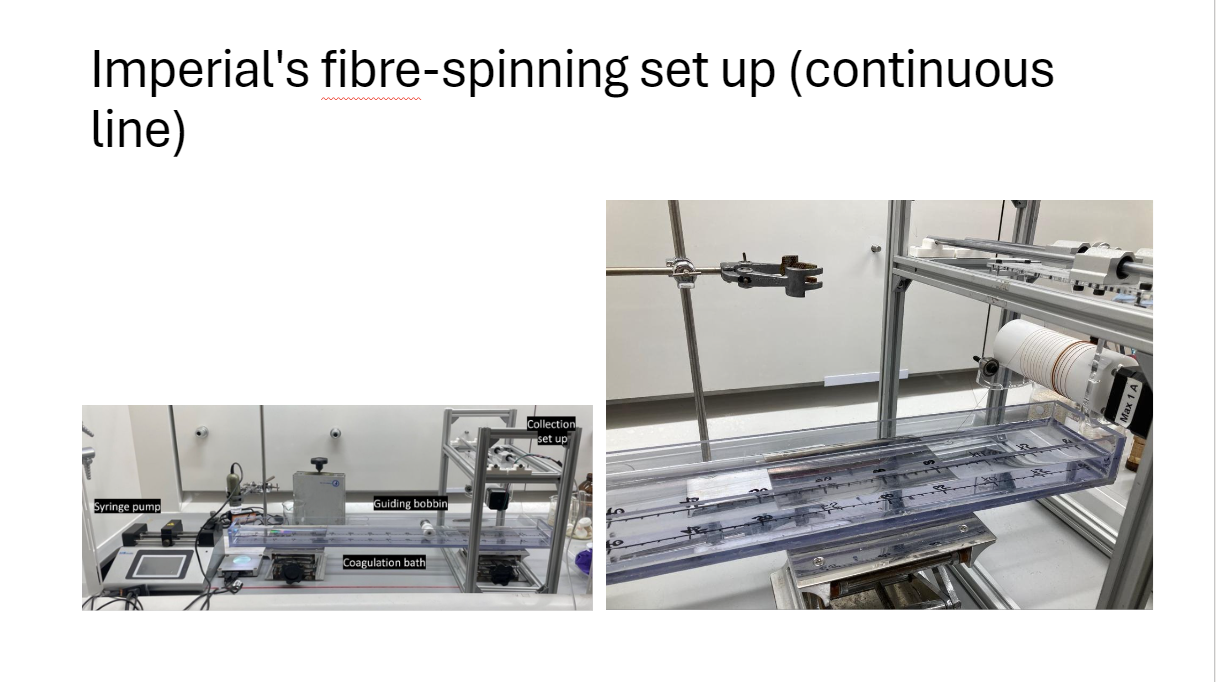

If we can work out how to make a large enough quantity of good quality fibre, we hope that will stimulate, you know, the take up of the technology into a kind of industrial process.

We're not really expecting the fibres to reach the maximum performance of the current best carbon fibres, but to reach a good enough performance that they can be used in a whole range of applications, which are in need of carbon fibres, but cheaper, more sustainable ones, so particularly in automotive, to help with the electrification of the automotive sector.

We're hoping that we will have found, um, that it's possible to produce better quality fibres from lignin than it has been. previously been achieved, that the performance is good enough to start considering, uh, their practical application. Then there's a process of scaling up and showing that that can be transferred to a more realistic manufacturing process.

NARRATOR

So, in the not-too-distant future, bikes which were once made from wood and could barely be lifted may return to their plant-based roots, this time a good deal lighter and speedier.

Some photos of the project