Measurement of Microstructural Damage in Cylindrical Components using Guided Waves

Creep damage in high temperature pipes is a significant challenge to industry as it involves high value components whose integrity is critical to safety. This project aims to develop a novel Guided Wave Testing (GWT) method capable of detecting microstructural material damage, such as creep. GWT is an established method of Non-Destructive Evaluation, which is used worldwide for the inspection of petrochemical and power station components, primarily pipelines. Its principal attraction is that it can inspect the full volume of the material of the components very rapidly.

Observations in the field have shown that GWT signals can be affected, albeit slightly, by creep damage of the components. This project aims to understand the interactions of creep damage with guided wave propagation.

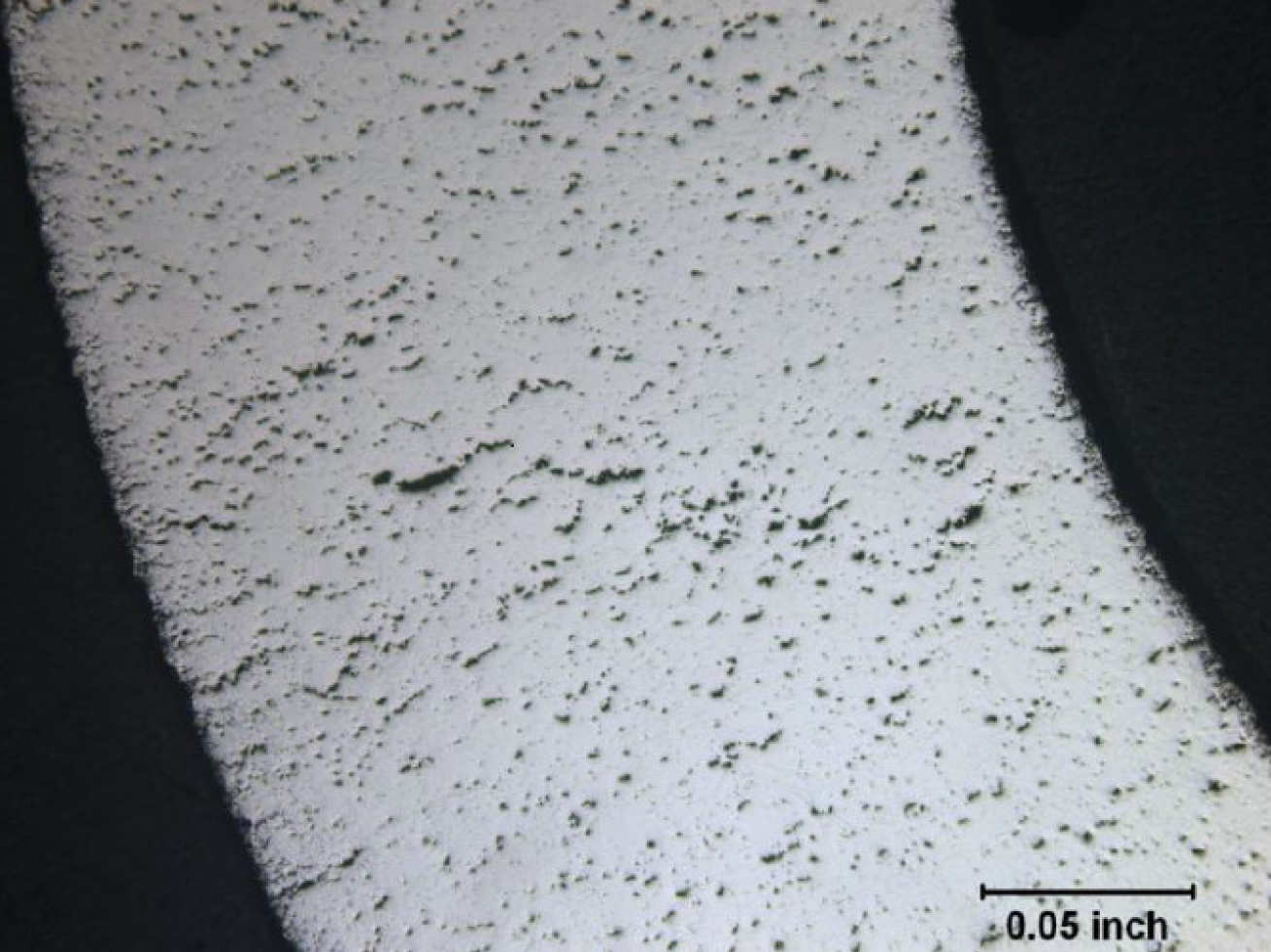

Voids and cracks that are found in creep damaged material are on a scale much smaller than the wavelength used in guided wave testing. In this regime effective material properties can be used to describe interactions as an approximation. A reduction in the effective stiffness of creep damaged material has been predicted by finite element modelling. Experiments are underway to experimentally validate these findings and whether new inspection methodologies can be developed to take advantage of this.